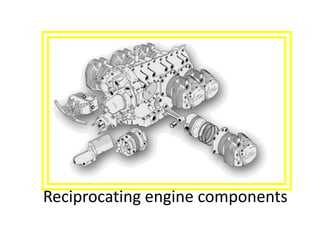

Piston engine construction

- 2. Crankcase • The crankcase is that part of the engine block below the cylinders. It supports and encloses the crankshaft and provides a reservoir for the lubricating oil. • The crankcase holds all of the engine parts in alignment and supports the cylinders and crankshaft • It provides a place to mount the engine to the aircraft • Constructed of aluminum alloy • Divided into sections (radial)

- 3. Crankcase • Nose section - Houses prop shaft and bearings • Power section - mount for cylinders • Fuel induction section - intake tubes, blower, manifolds (supercharger) • Accessory section - mounts for magnetos, pumps, generators (magnesium)

- 4. Crankcase • Opposed crankcase • Sections are not as distinct as in the radial and the crankcase splits from front to rear instead of in radial sections

- 5. Crankshaft

- 6. Crankshaft • Constructed of chrome-nickel-molybdenum-steel • May be one piece or as many as three separate pieces • The crankshaft rotates within the crankcase and is supported by main bearing journals • Crankshaft throws or crankpins are off center and account for the reciprocating motion of the pistons

- 7. Crankshaft

- 8. Crankshaft • Counterweights are used to reduce vibration but they are rigid • Counterweights are used in piston engines because the power pulses and movement of the pistons create large amounts of vibration • Vibration shortens airframe and engine life and can lead to premature component failure

- 9. Crankshaft • 2 Piece Crankshaft With Counterweights (Single Throw, Single Cylinder)

- 10. Camshaft

- 11. Camshaft • Used to open the valves for intake and exhaust • Must be mechanically coupled to the crankshaft for timing purposes (gears, belts, chains) • The camshaft consists of bearing journals and lobes spaced along the shaft • Each lobe is positioned to open and close a valve at a specific time Lobe

- 12. Sump

- 13. Sump • reservoir for the lubricating oil. • A wet sump is a lubricating oil management design for piston engines which uses the crankcase as a built-in reservoir for oil. • Piston engines are lubricated by oil which is pumped into various bearings, and thereafter allowed to drain to the base of the engine under gravity. • A wet sump offers the advantage of a simple design, using a single pump and no external reservoir.

- 15. Accessory gearbox • The accessory drive gearbox is most often attached directly to the outside cases of the engine at or near the bottom. • The accessory gearbox is driven the crankshaft of the engine. • The gearbox has attachment pads on it for accessories that need to be mechanically driven.

- 16. Cylinder barrel

- 17. Cylinder Barrel • Chrome-molybdenum or nickel-molybdenum steel • Used to guide and seal piston and to mount cylinder assembly to head • Barrel threads into head to form cylinder assembly

- 18. Cylinder head • Valve • Spark plug

- 19. Cylinder head • Cylinder heads • Constructed of cast aluminum alloy • Provides combustion chamber, and mounting areas for spark plugs and valve parts

- 20. Cylinder head • The cylinder head is designed to transfer heat by conduction to the fins and then from the fins to the air by convection

- 21. Piston

- 22. Piston • Constructed of aluminum alloy • Parts include top, ring grooves, ring lands, skirt, and piston pin boss • Cooling fins on the bottom help the oil carry heat away from the piston top

- 23. Ring

- 24. Ring • Provide seal between cylinder wall and piston • Rings ride on a thin film of oil • Conduct heat from the piston out to the cylinder and the fins • Material is cast iron or chrome steel • Piston rings (type) • compression ring is to prevent gases from leaking by the piston during the compression and power strokes. • The oil ring, usually located just above the piston pin,it is an oil-regulating ring. This ring scrapes the excess oil from the cylinder walls and returns some of it, through slots, to the piston ring grooves.

- 25. Ring • The gap at the end of the rings allows for expansion and contraction and unevenness in the cylinder wall . • Always place the end gaps during ring installation away from each other to prevent losing compression.

- 26. Piston Pin

- 27. Piston Pin • The piston is attached to the connecting rod by the piston pin (wrist pin). • Piston pins are made of alloy steel with a precision finish • They are lubricated by splash from the crankcase or by pressure passages bored in the connecting rods • The pin is retained in the piston with clips or plugs to prevent cylinder wall scoring

- 28. Piston Pin • Three methods are commonly used for fastening a piston pin to the piston and the connecting rod

- 29. Connecting rod

- 30. Connecting Rod • Connecting Rod Assembly • The link between the crankshaft and the piston • Normally steel but some low powered engines use aluminum to save weight • Types include : Plain Rod Fork and blade rod Master and articulated