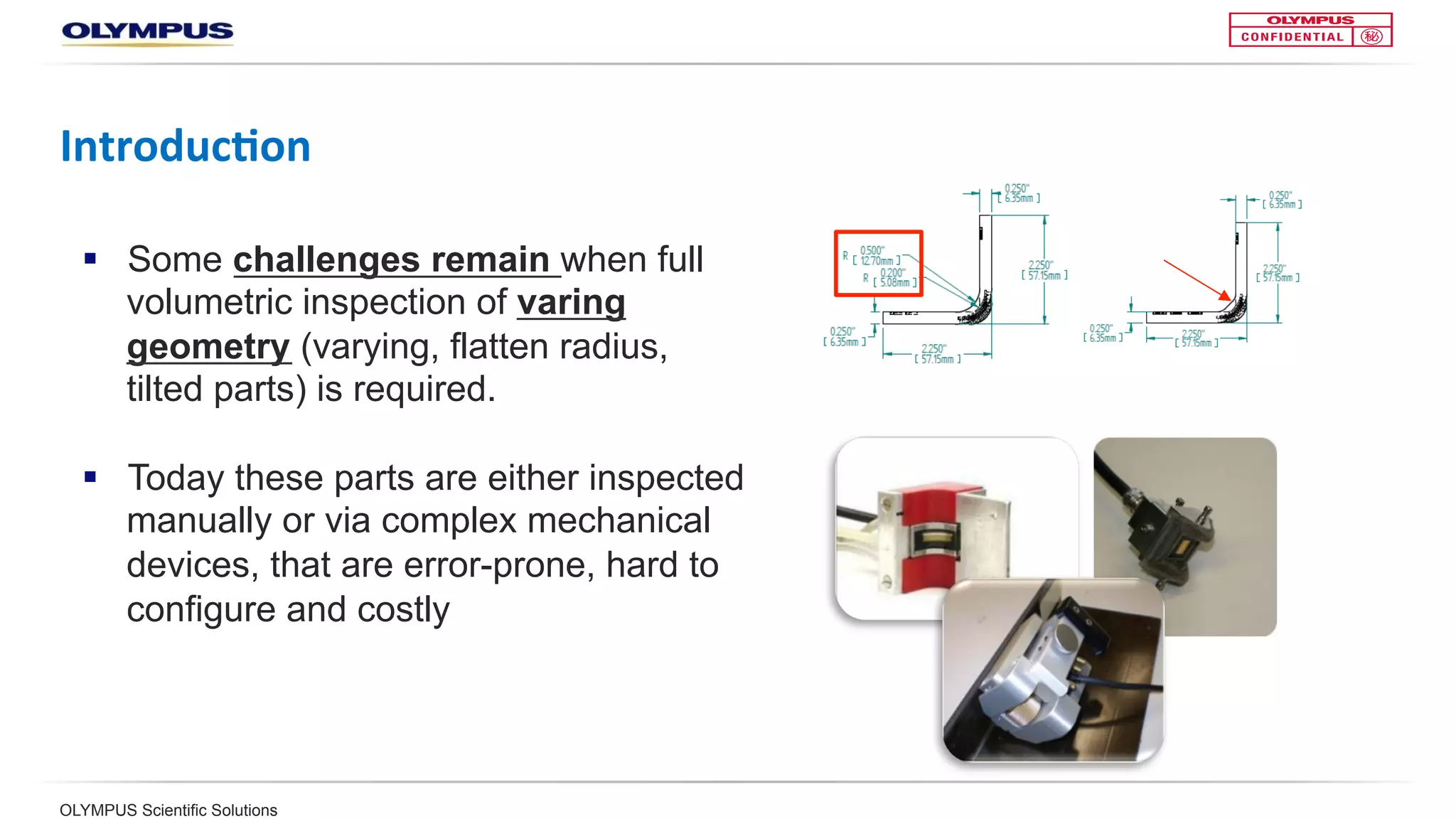

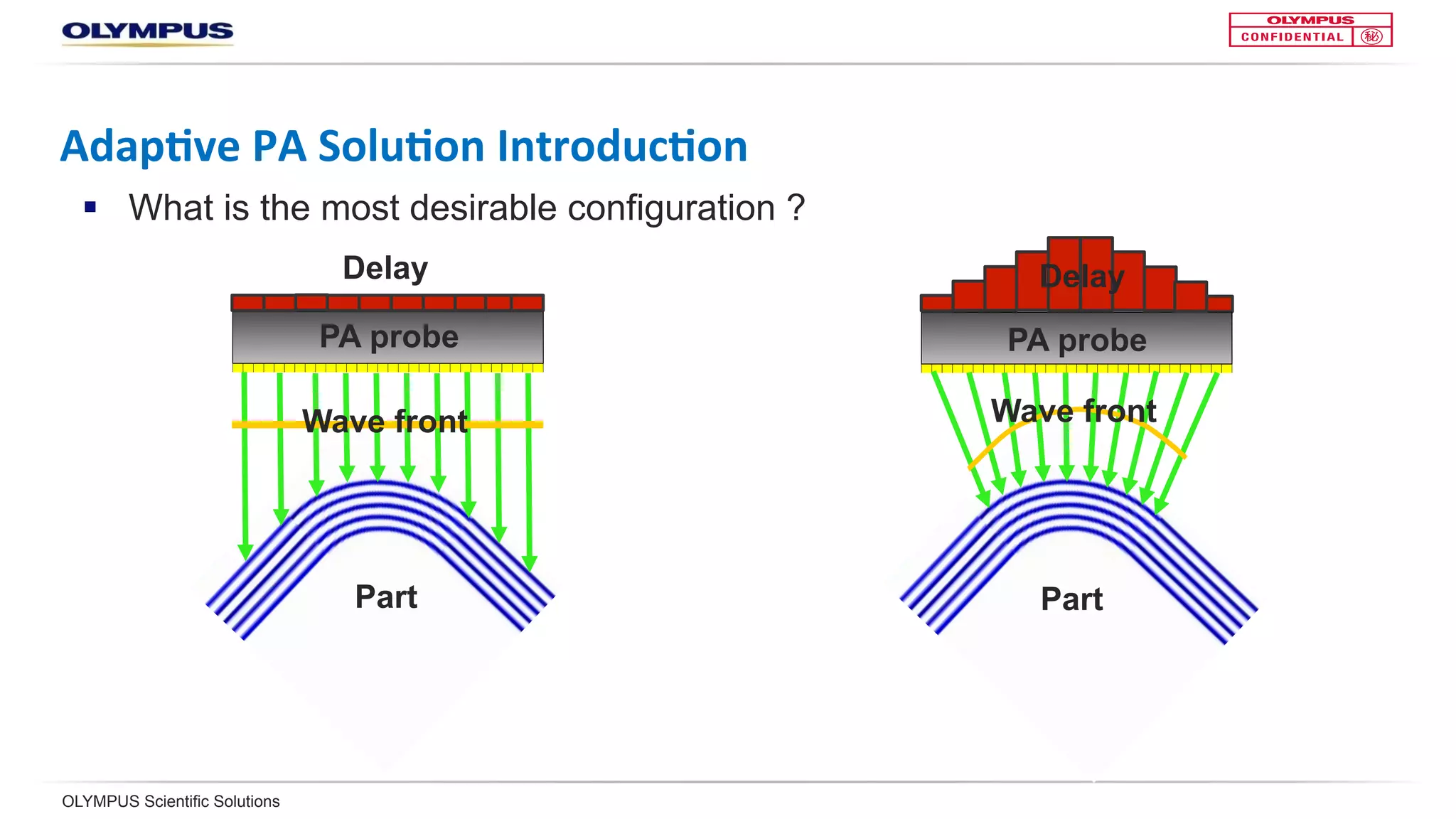

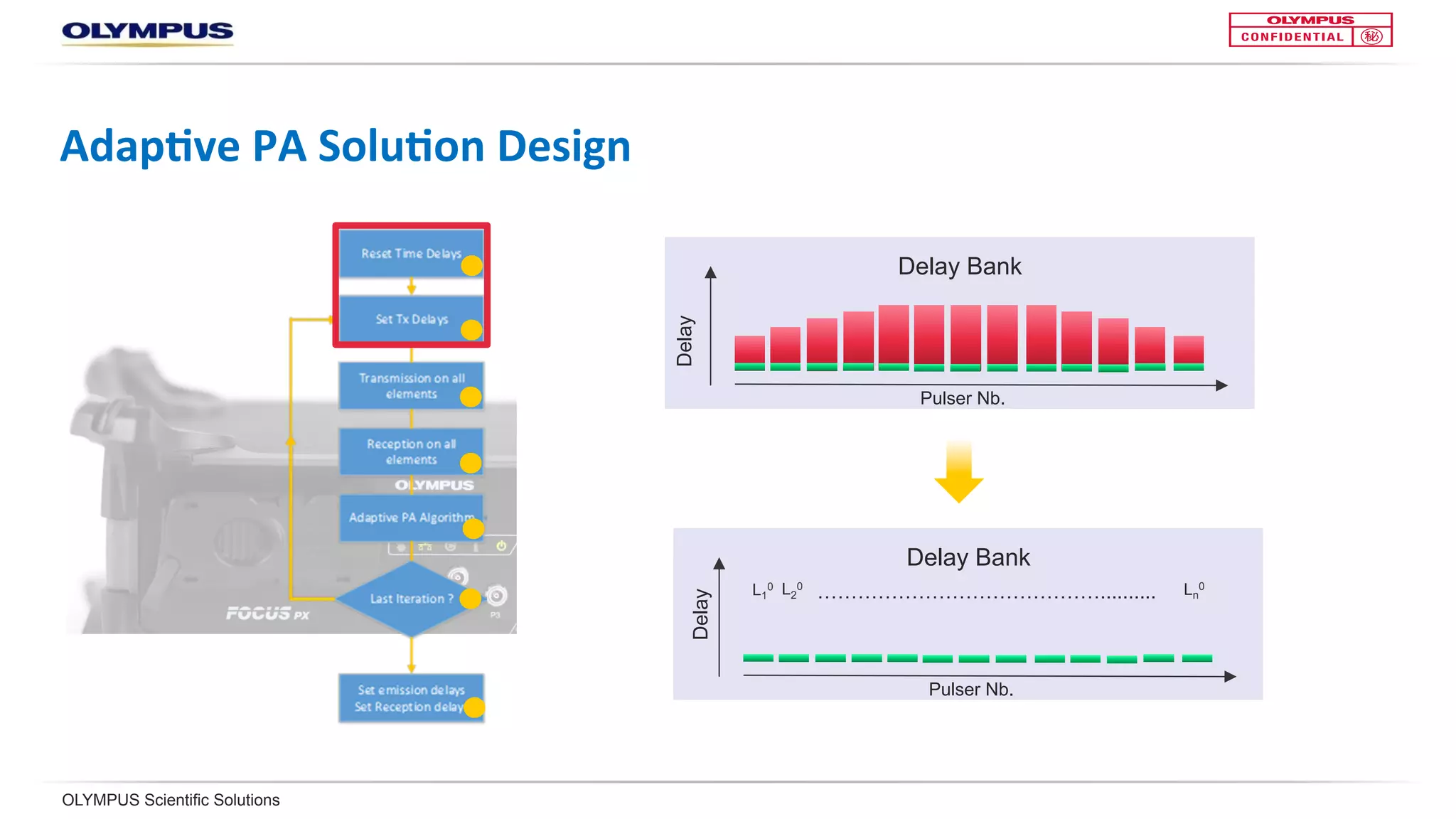

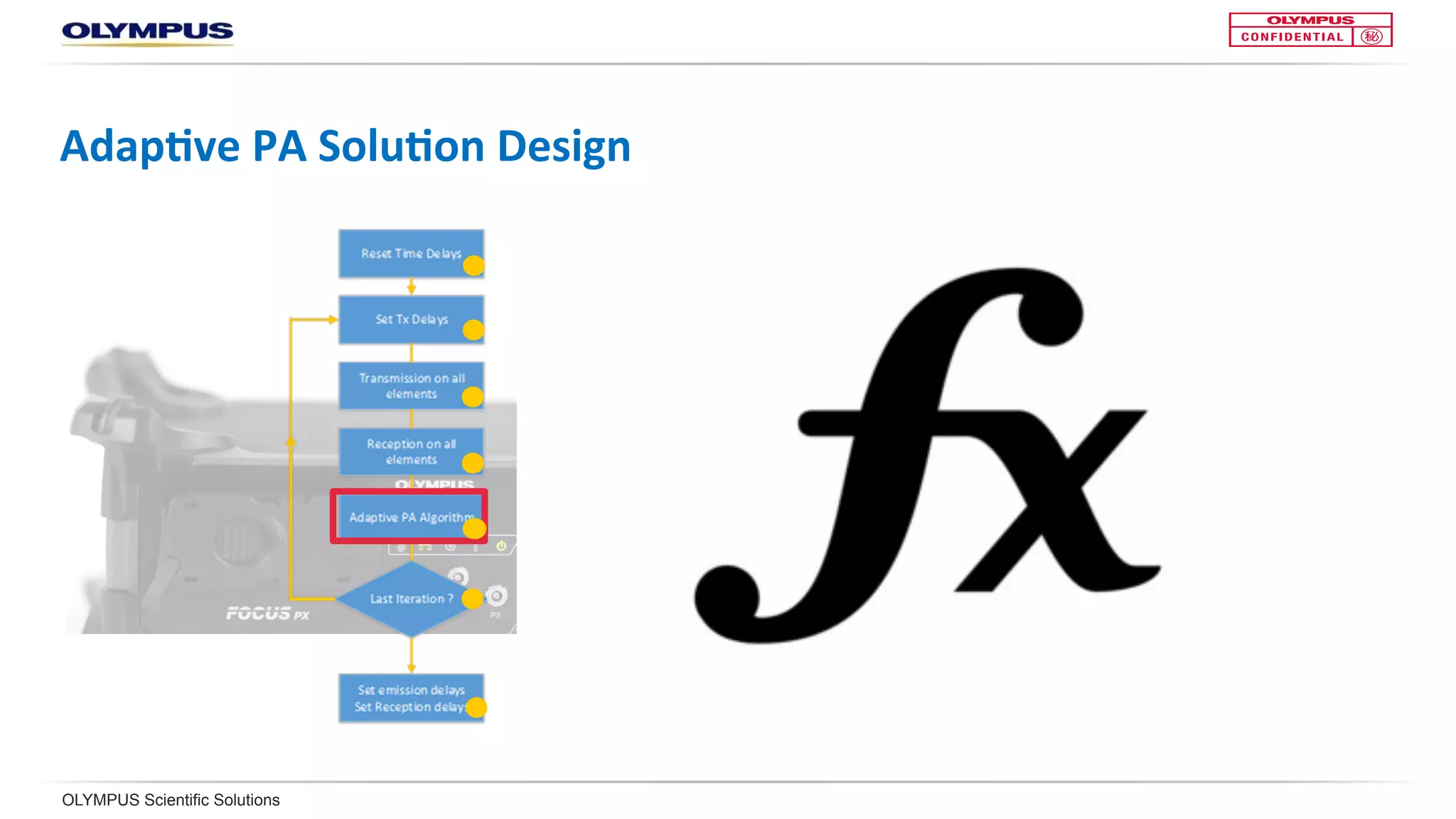

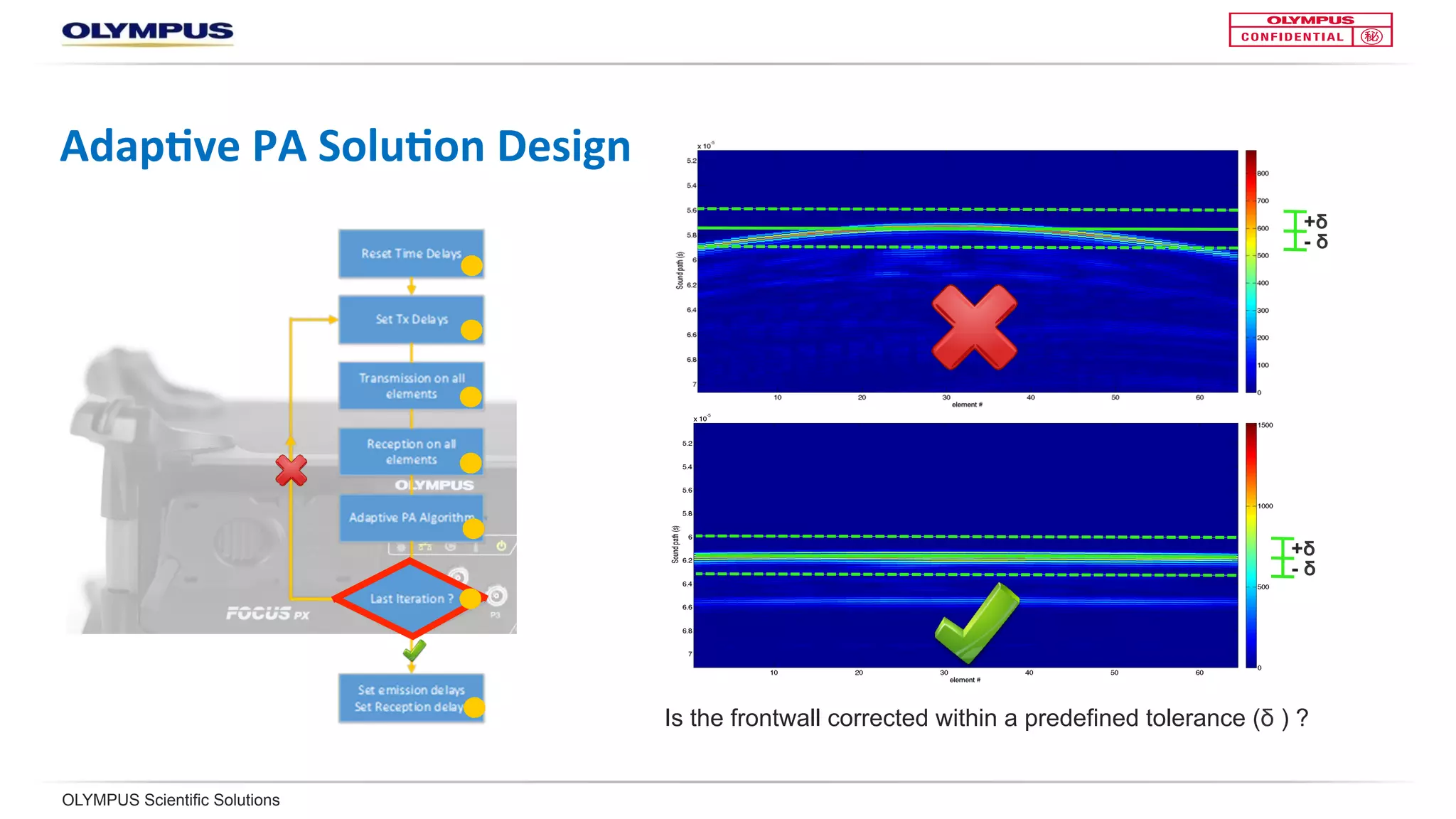

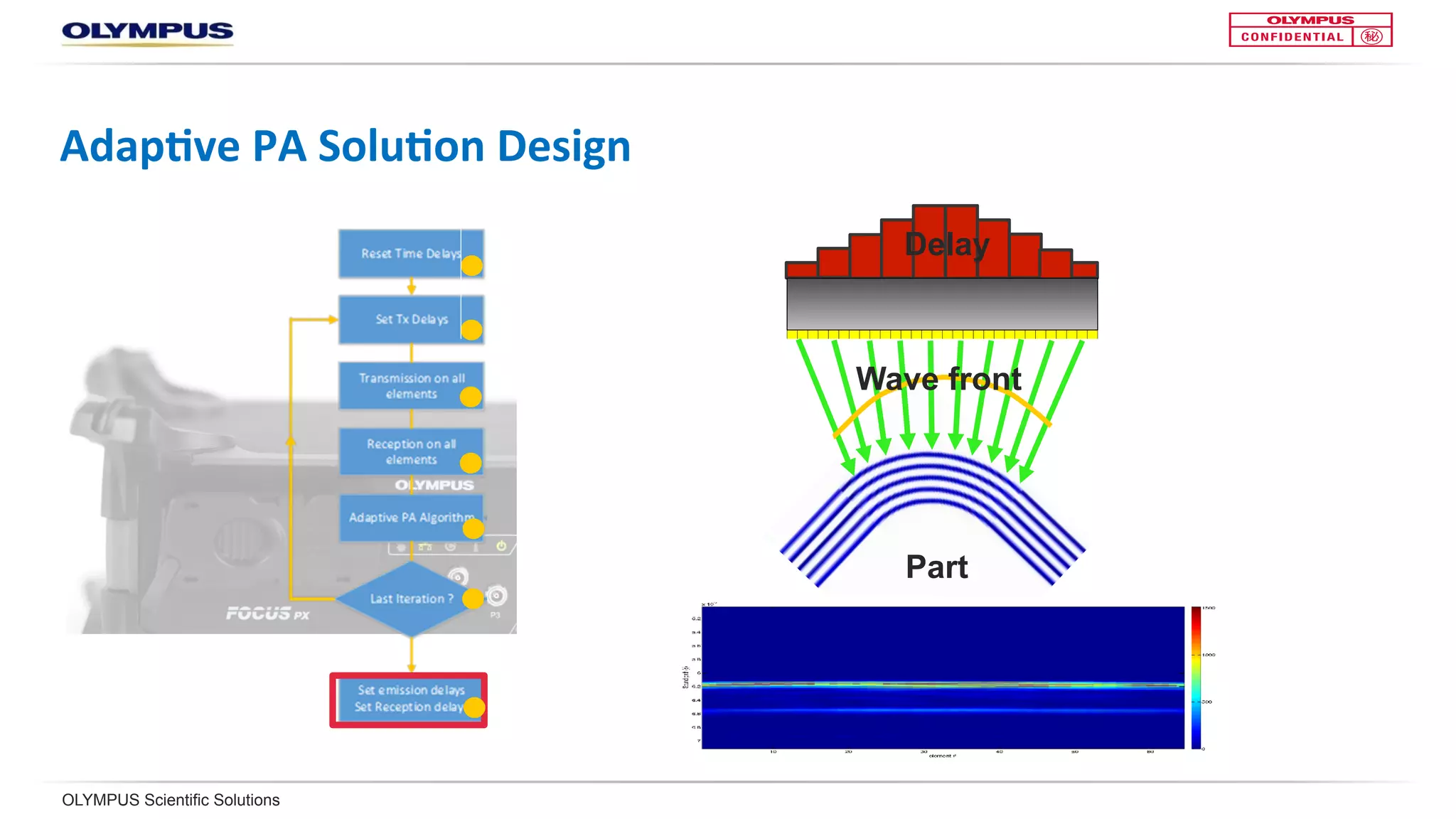

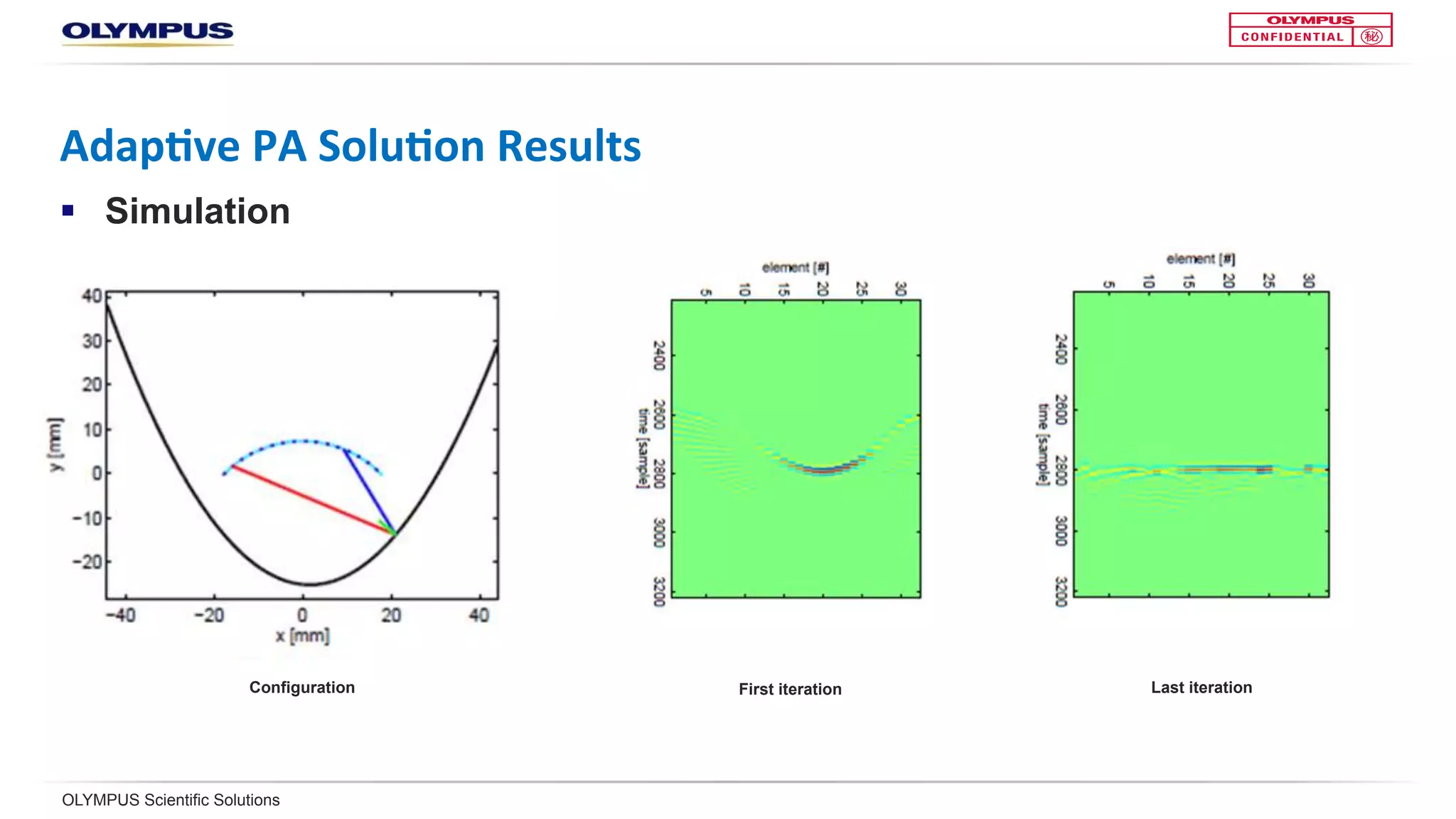

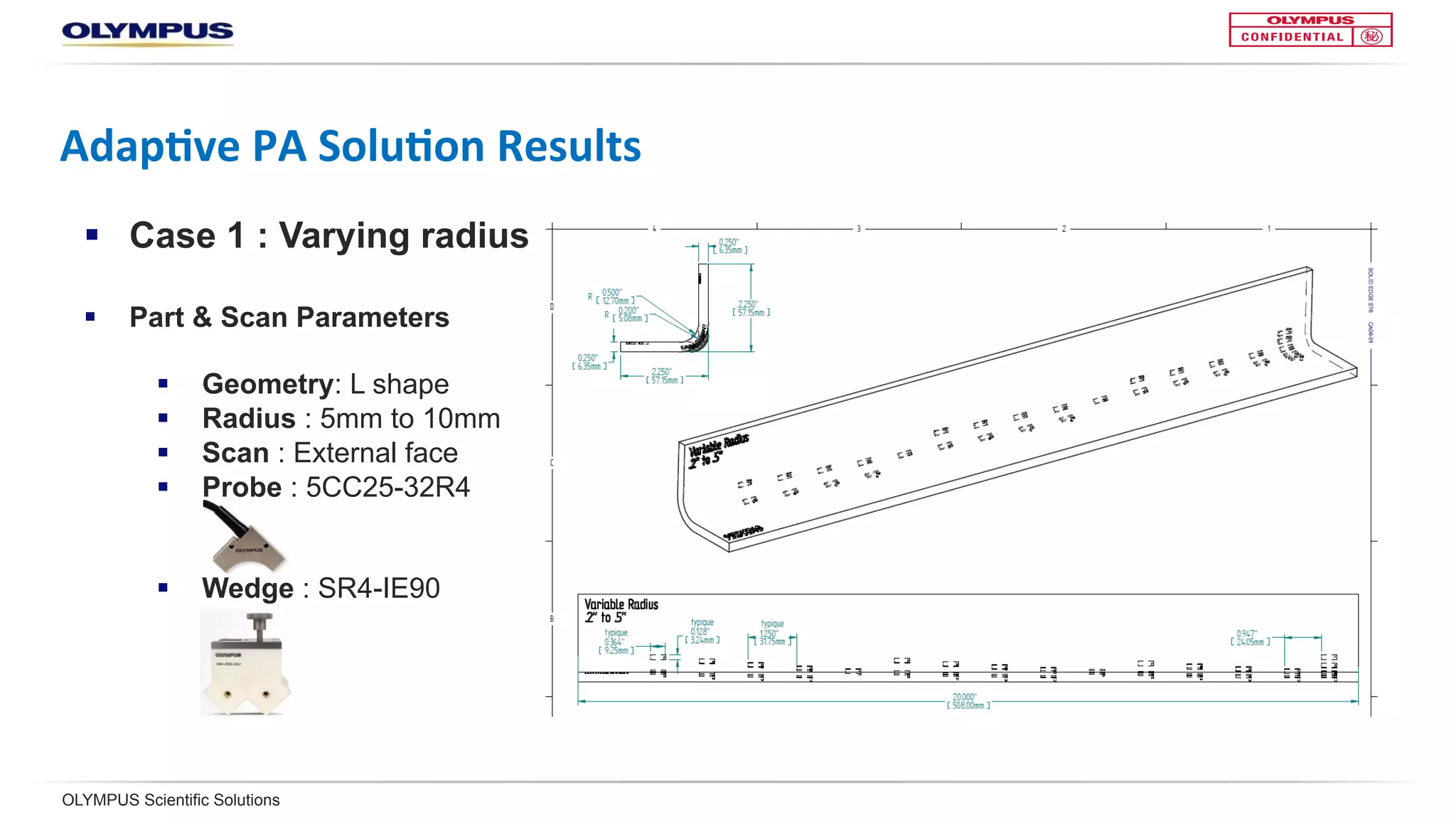

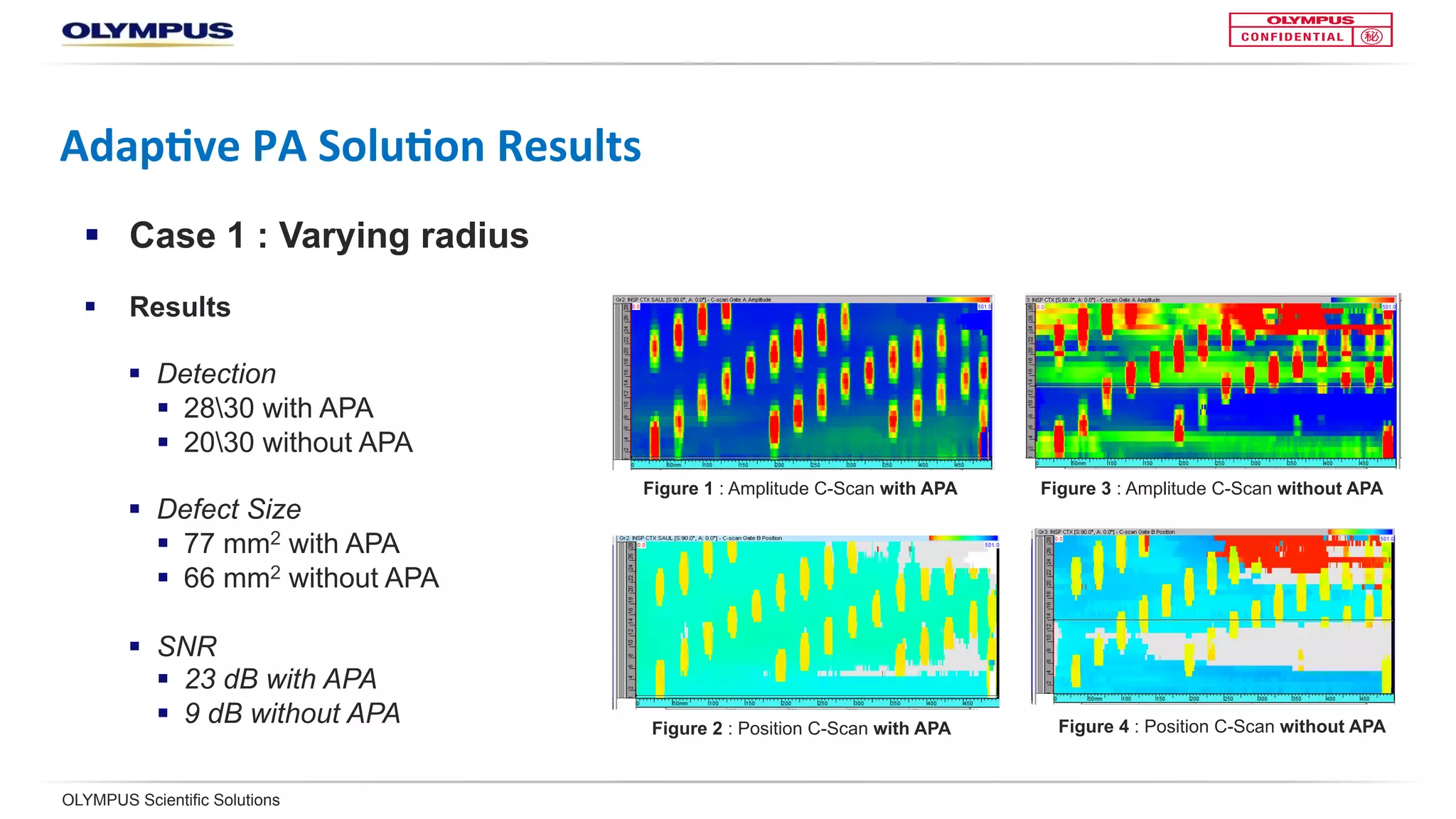

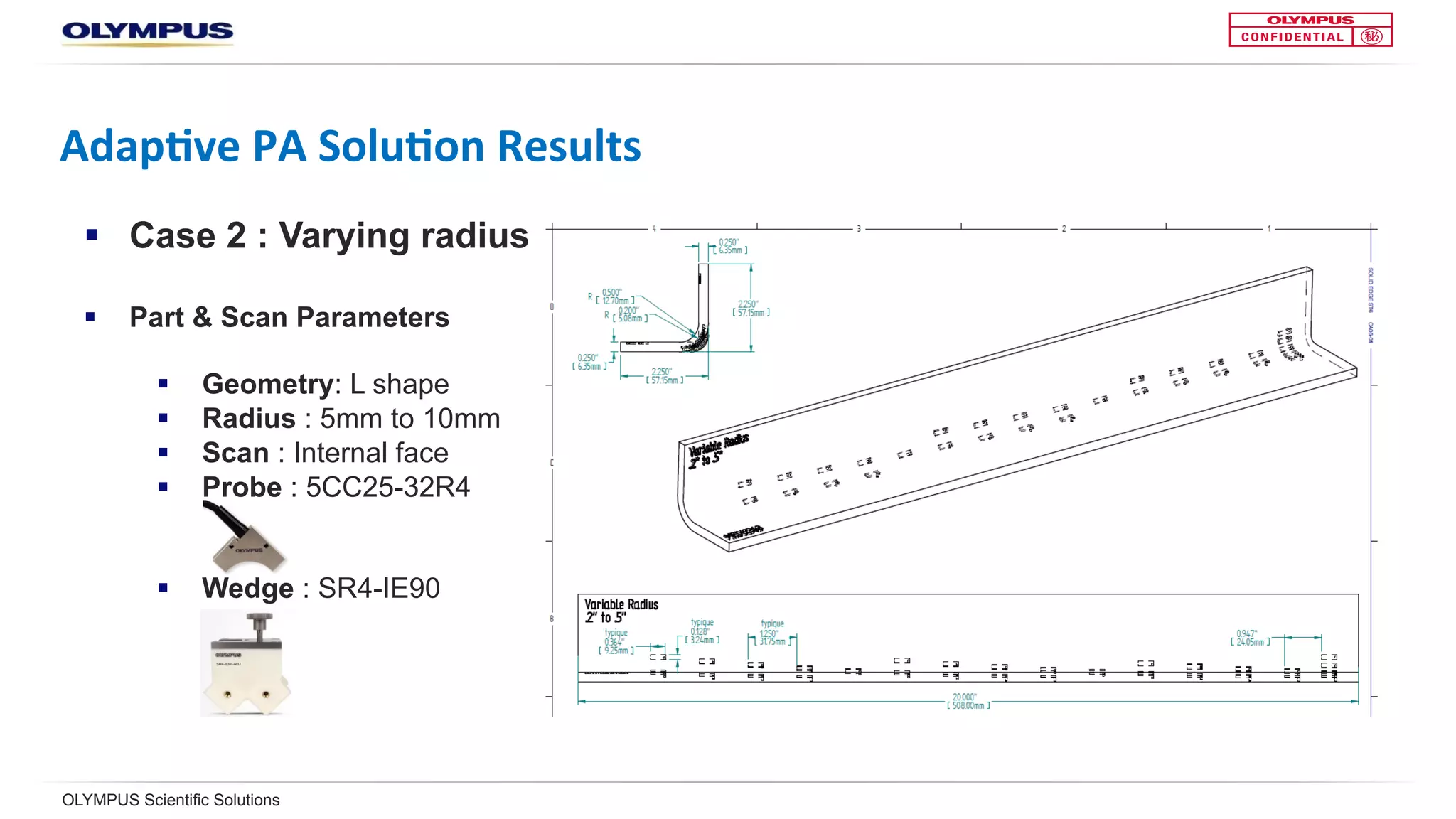

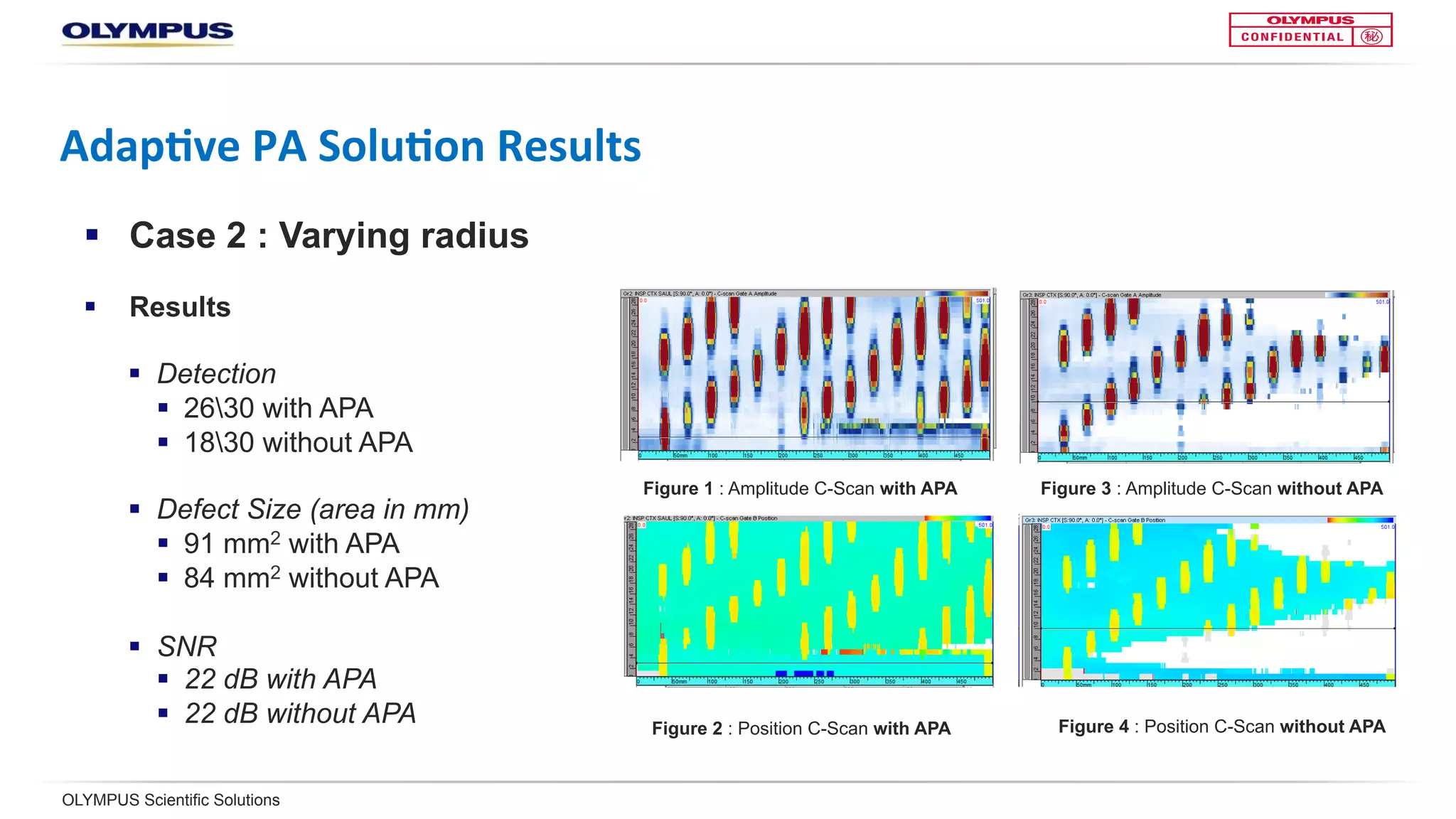

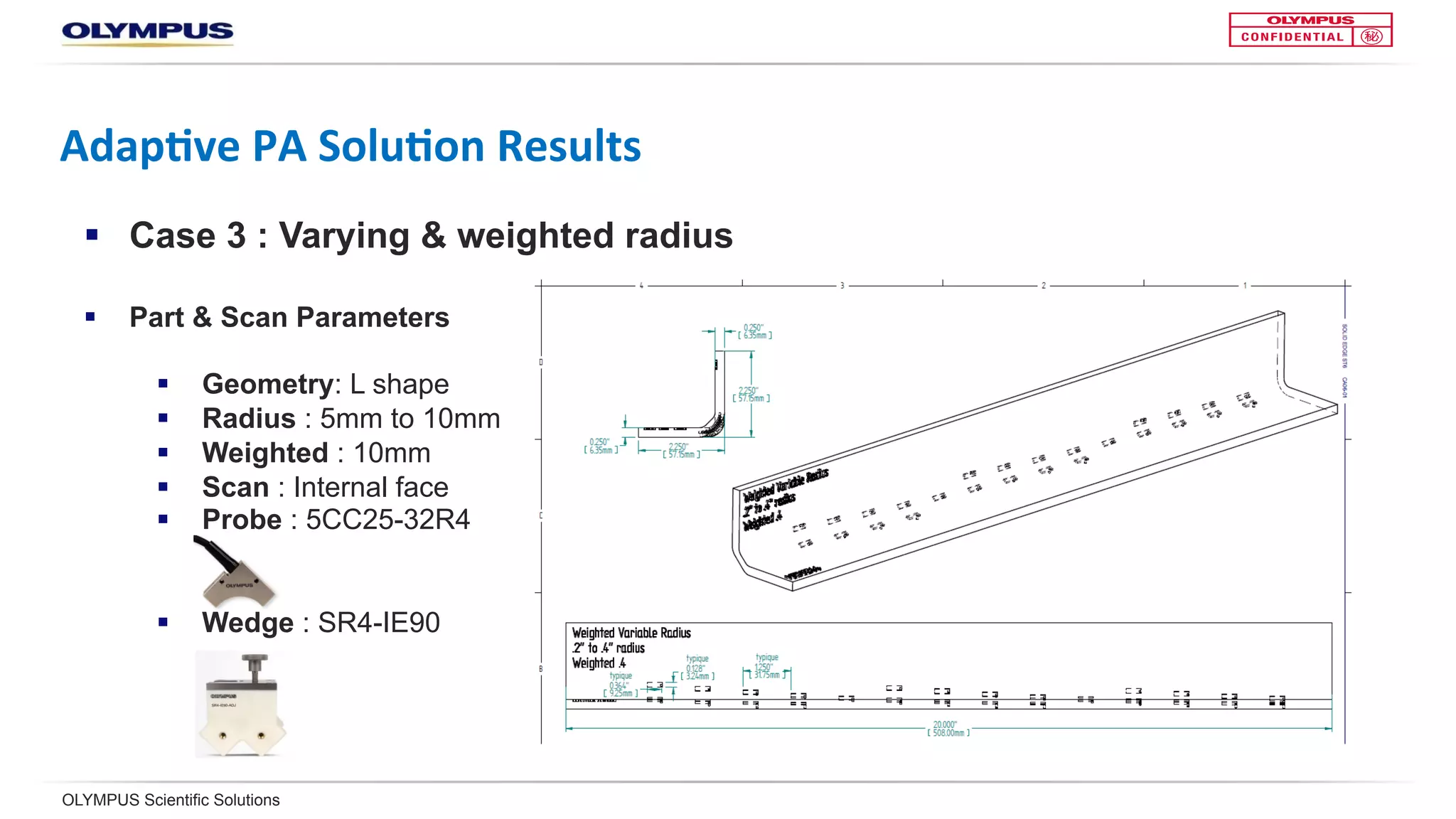

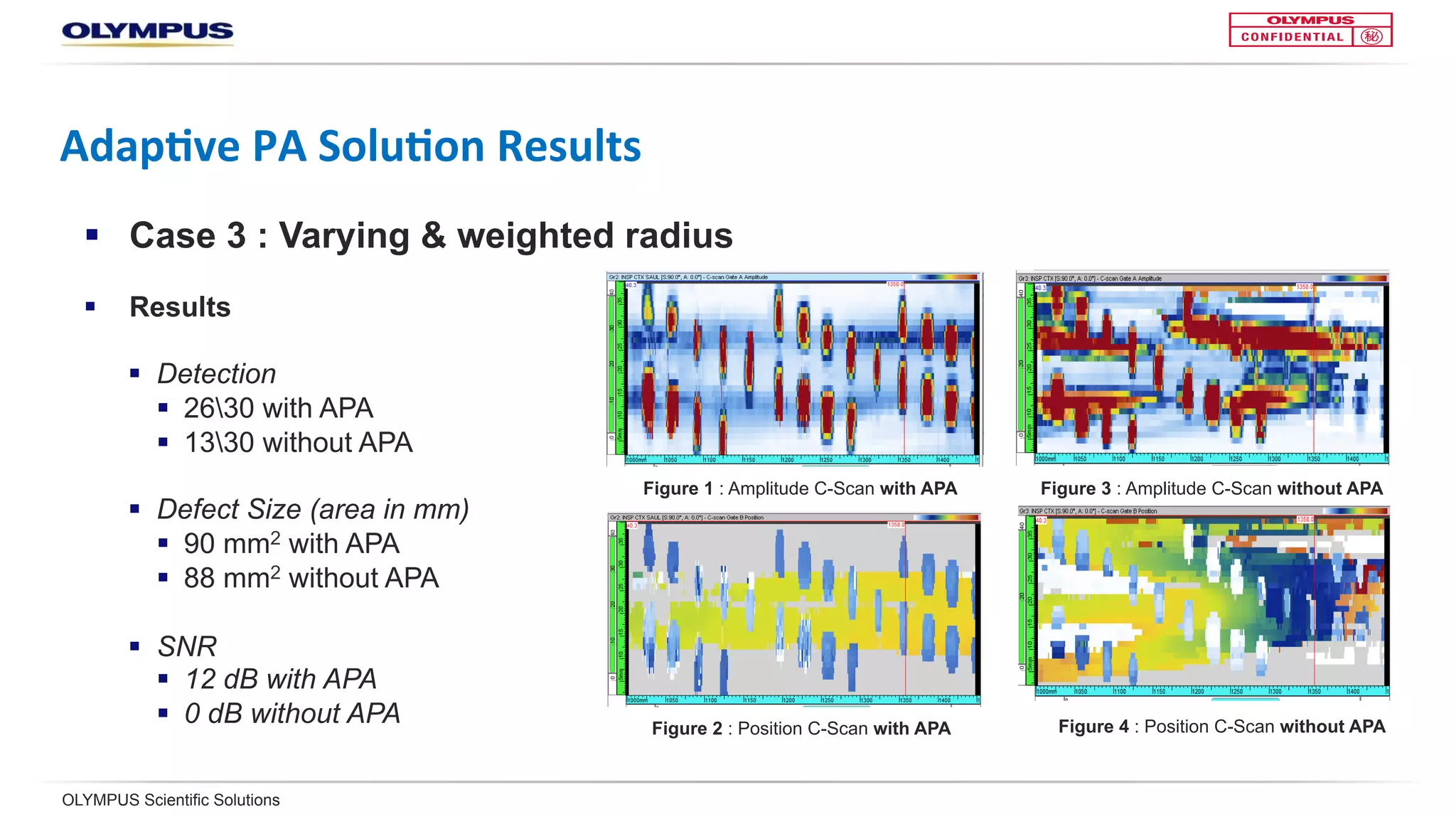

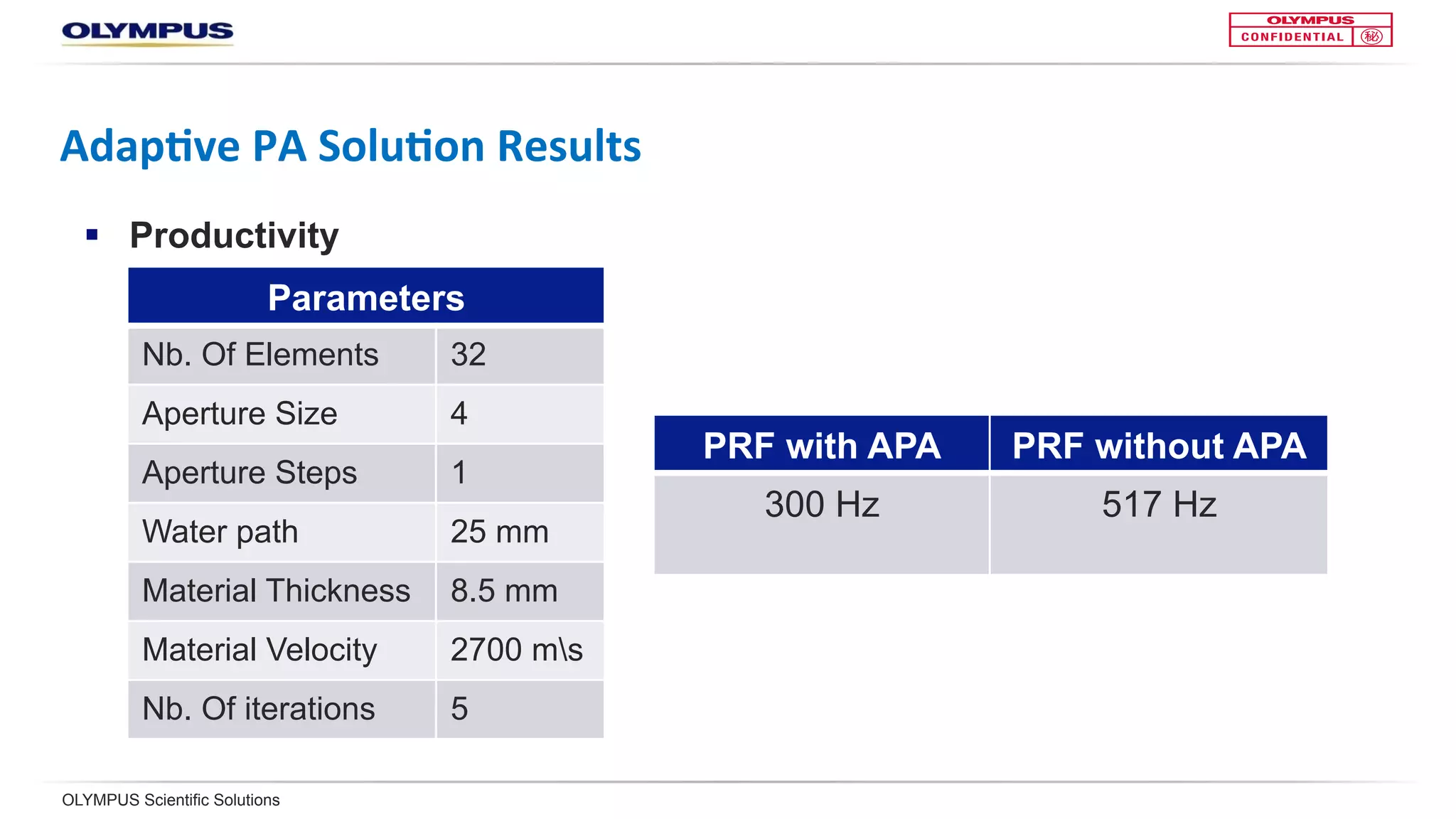

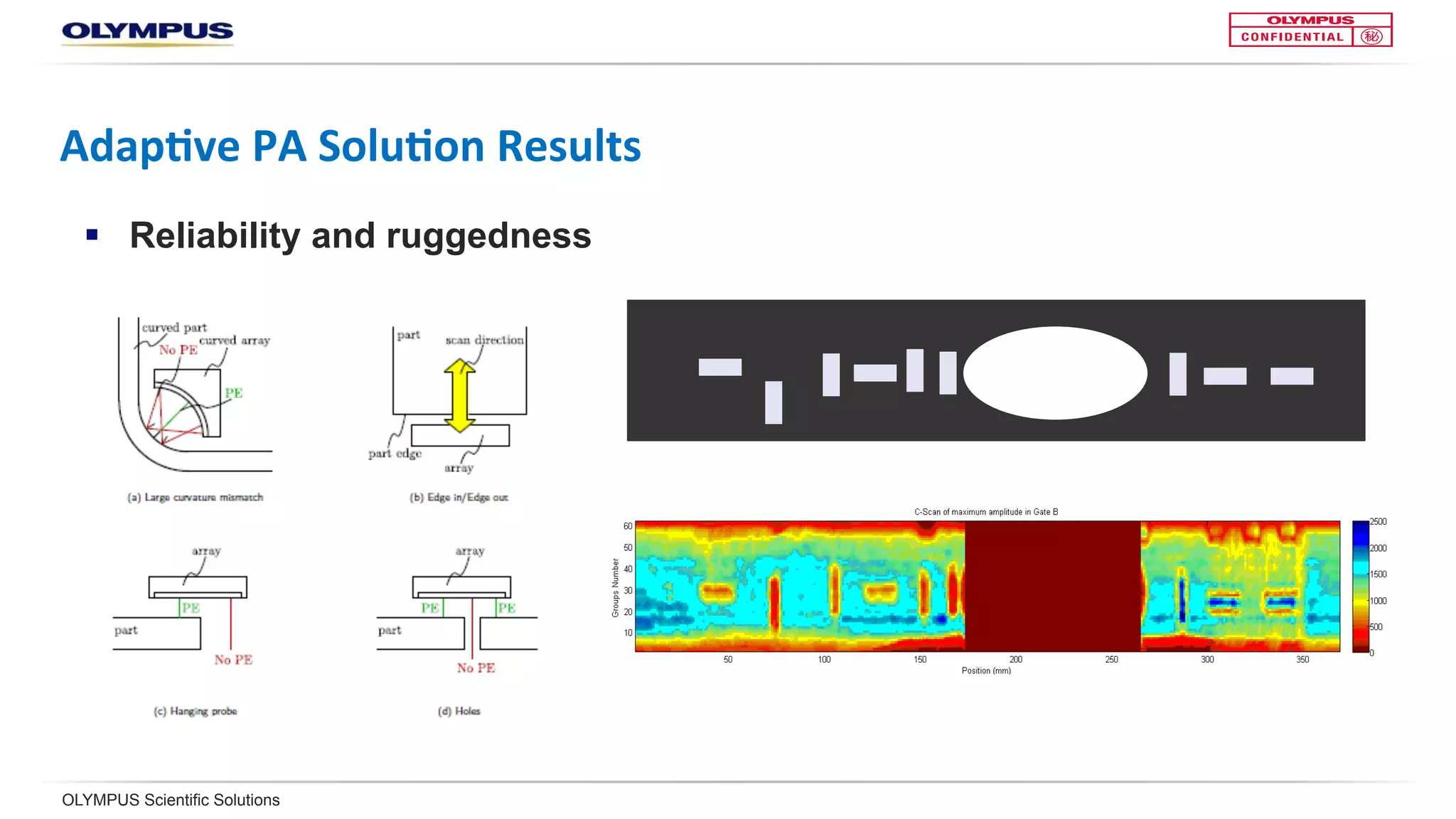

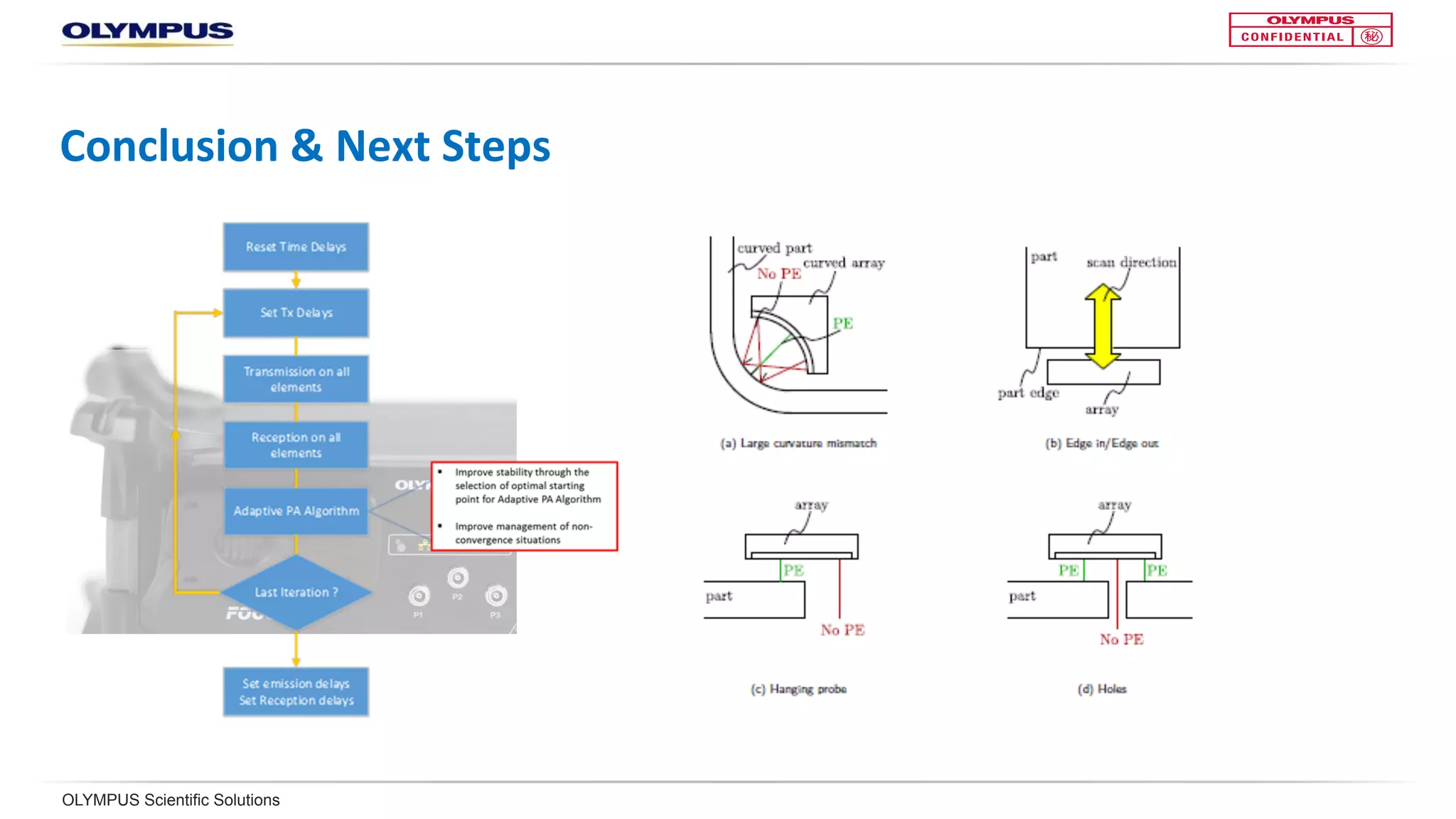

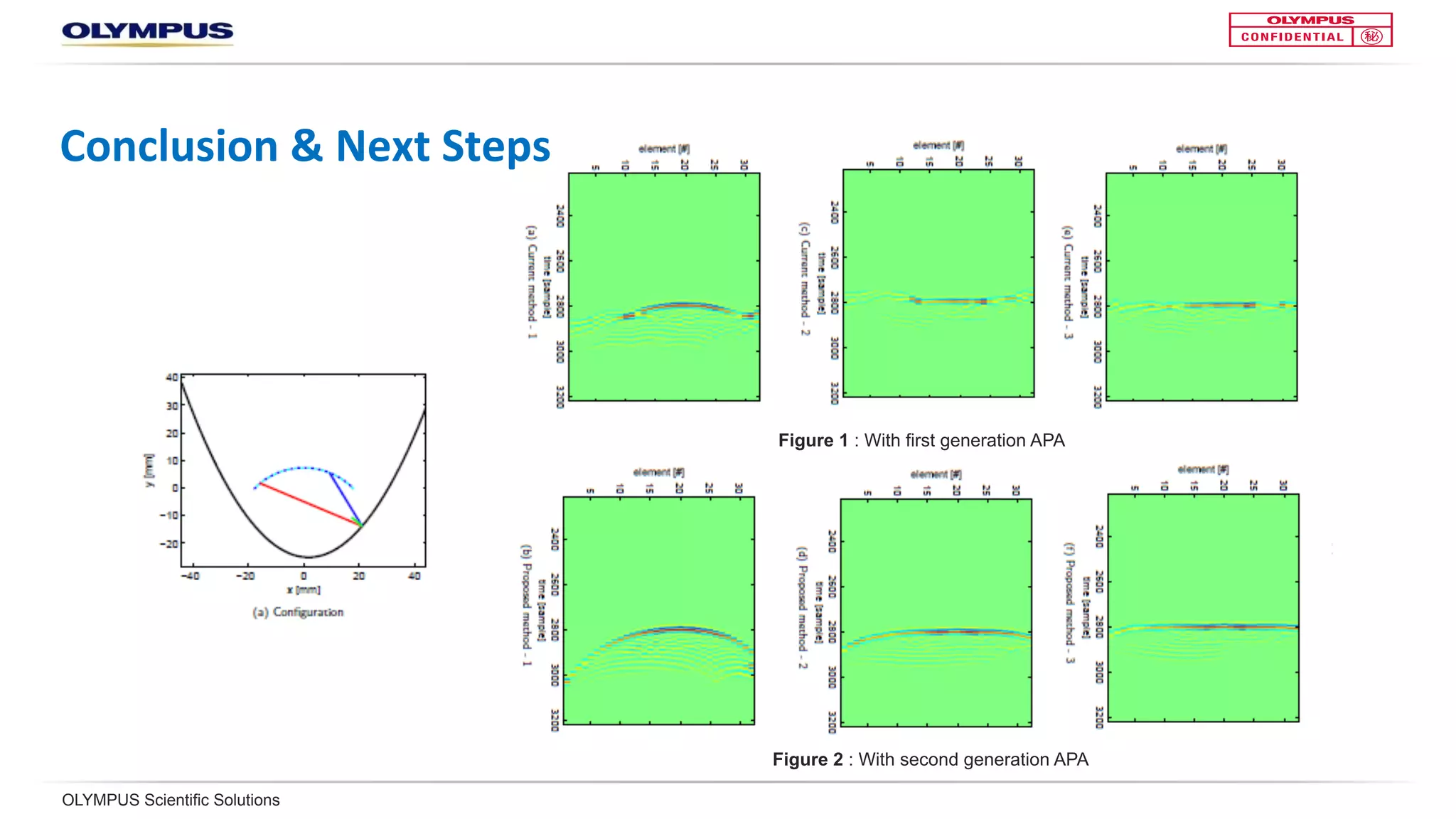

The document discusses Olympus NDT Canada's adaptive phased array (APA) solution for inspecting complex geometry components in the aviation industry. It outlines the evolution of non-destructive testing (NDT) technologies, addressing challenges such as complex geometry and the need for skilled operators, while highlighting the benefits of APA for faster and more reliable inspections. Results from various cases demonstrate improved detection rates and defect size measurement when using the APA compared to traditional methods.