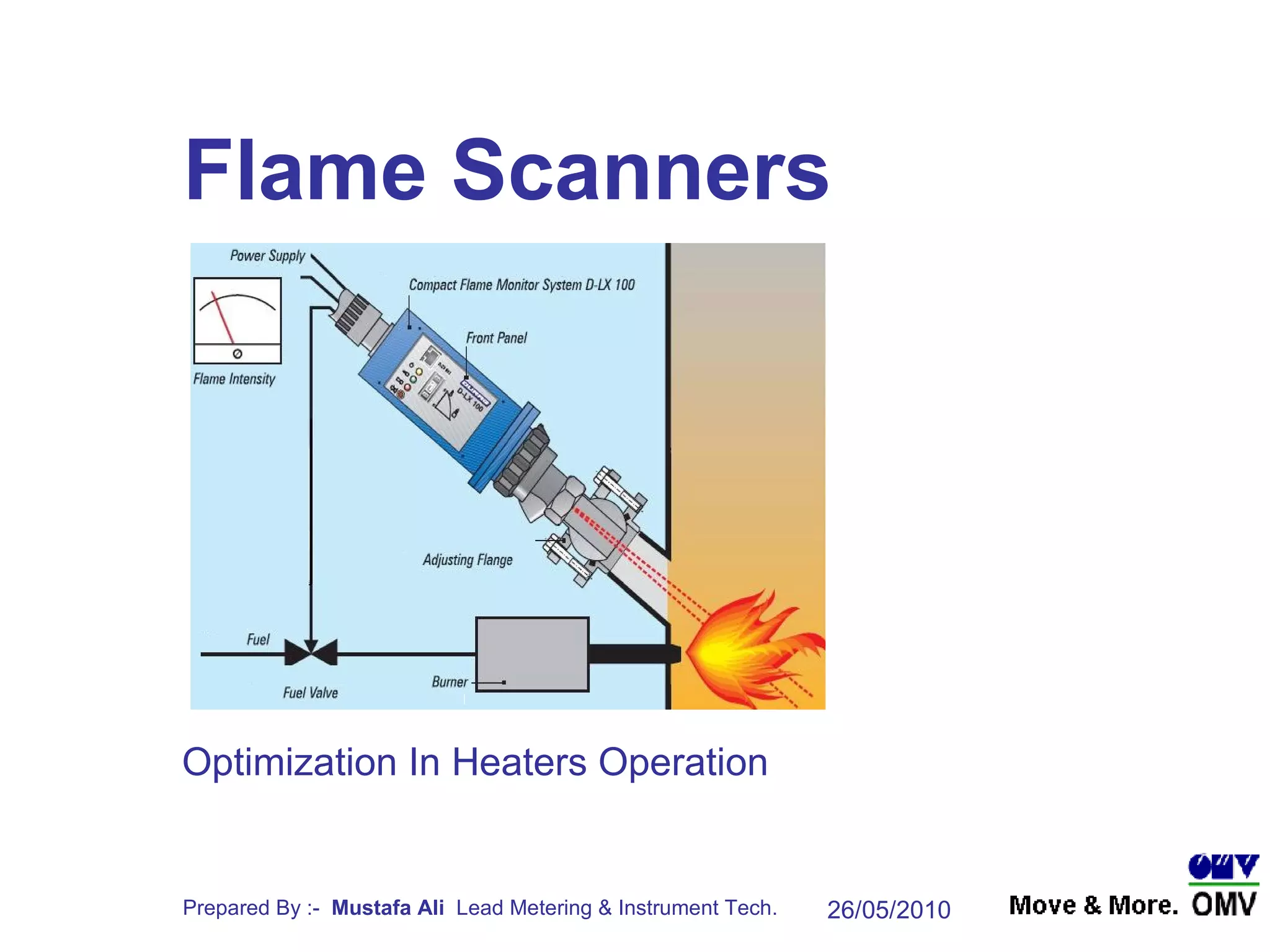

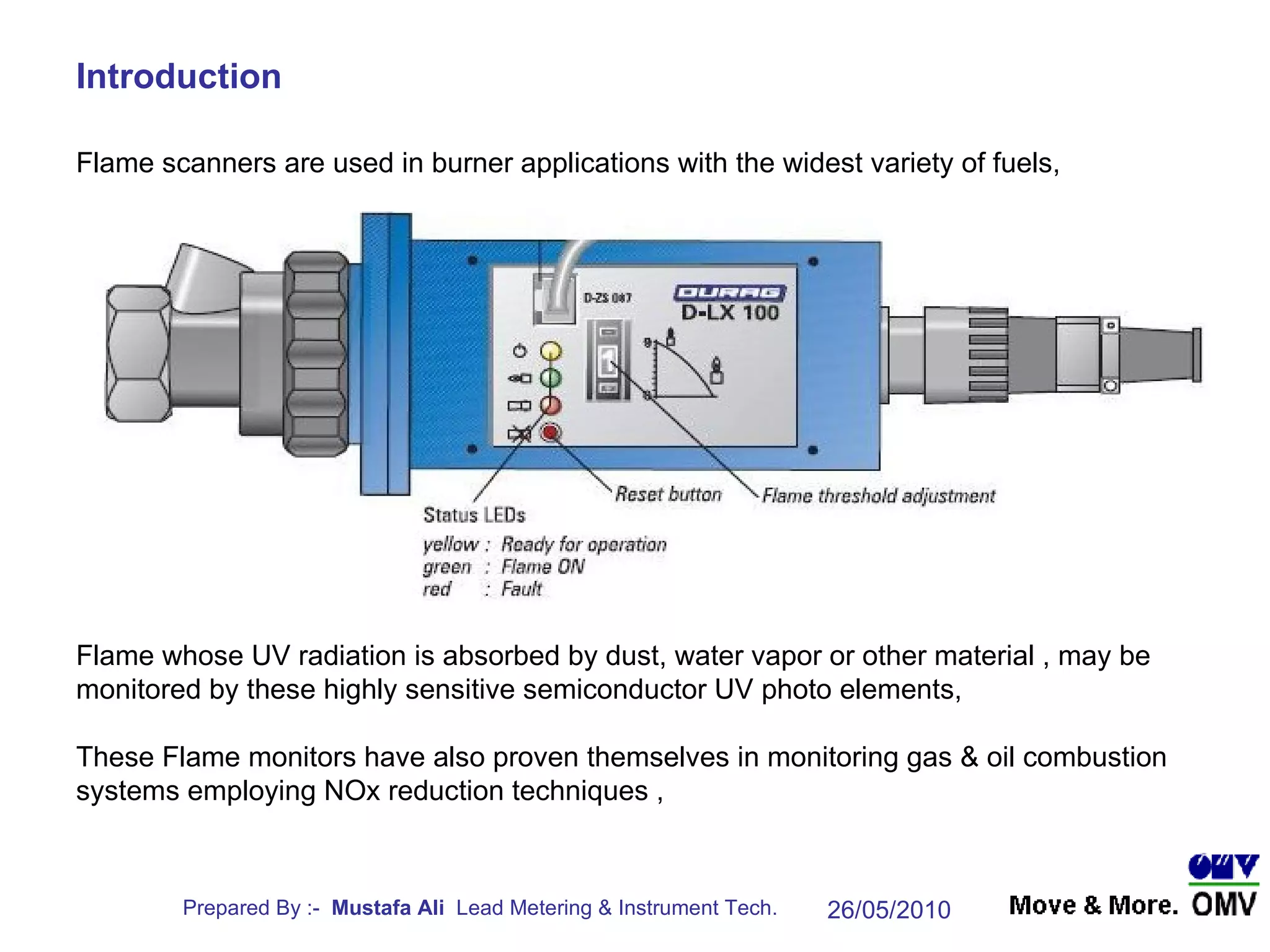

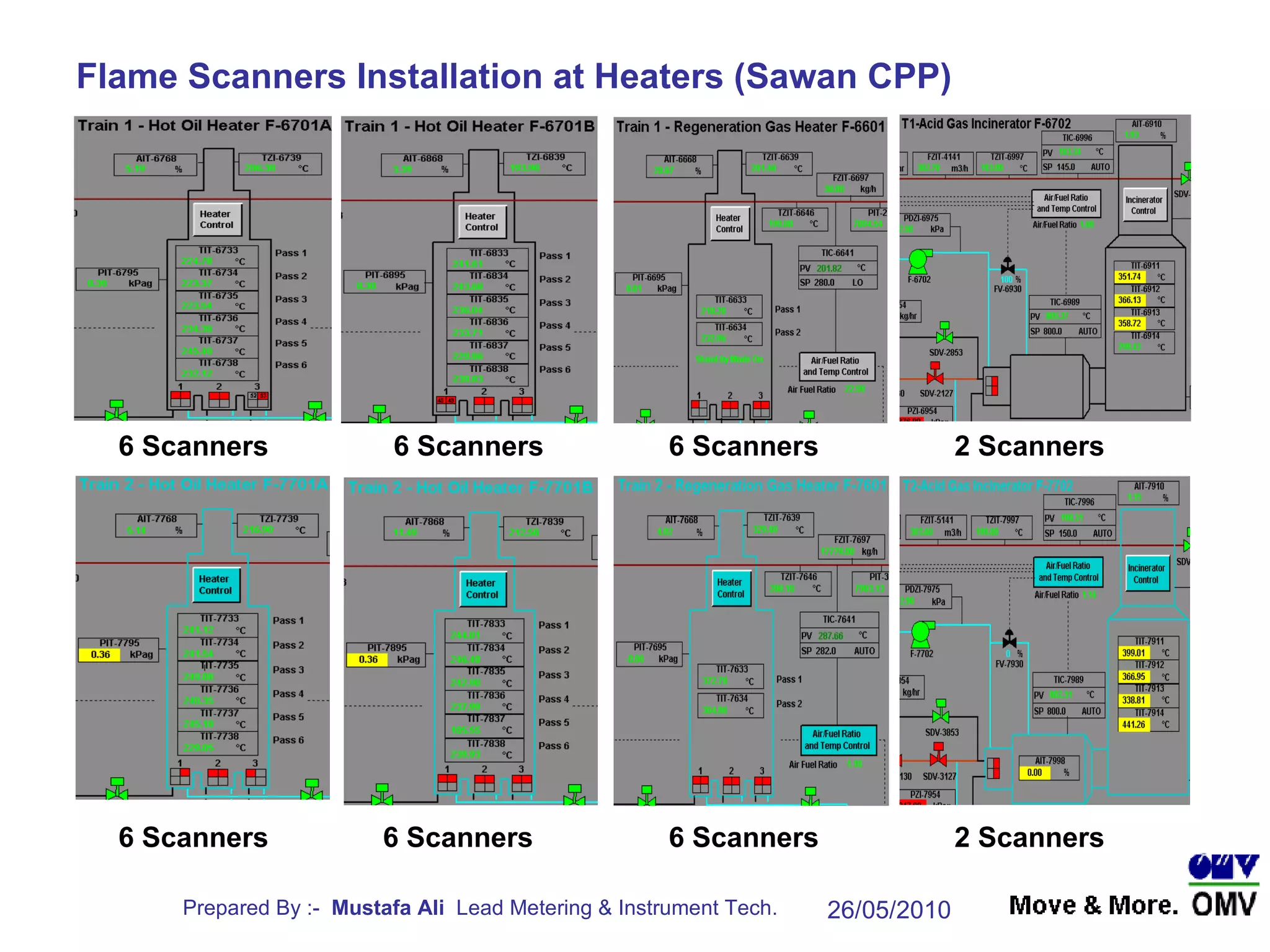

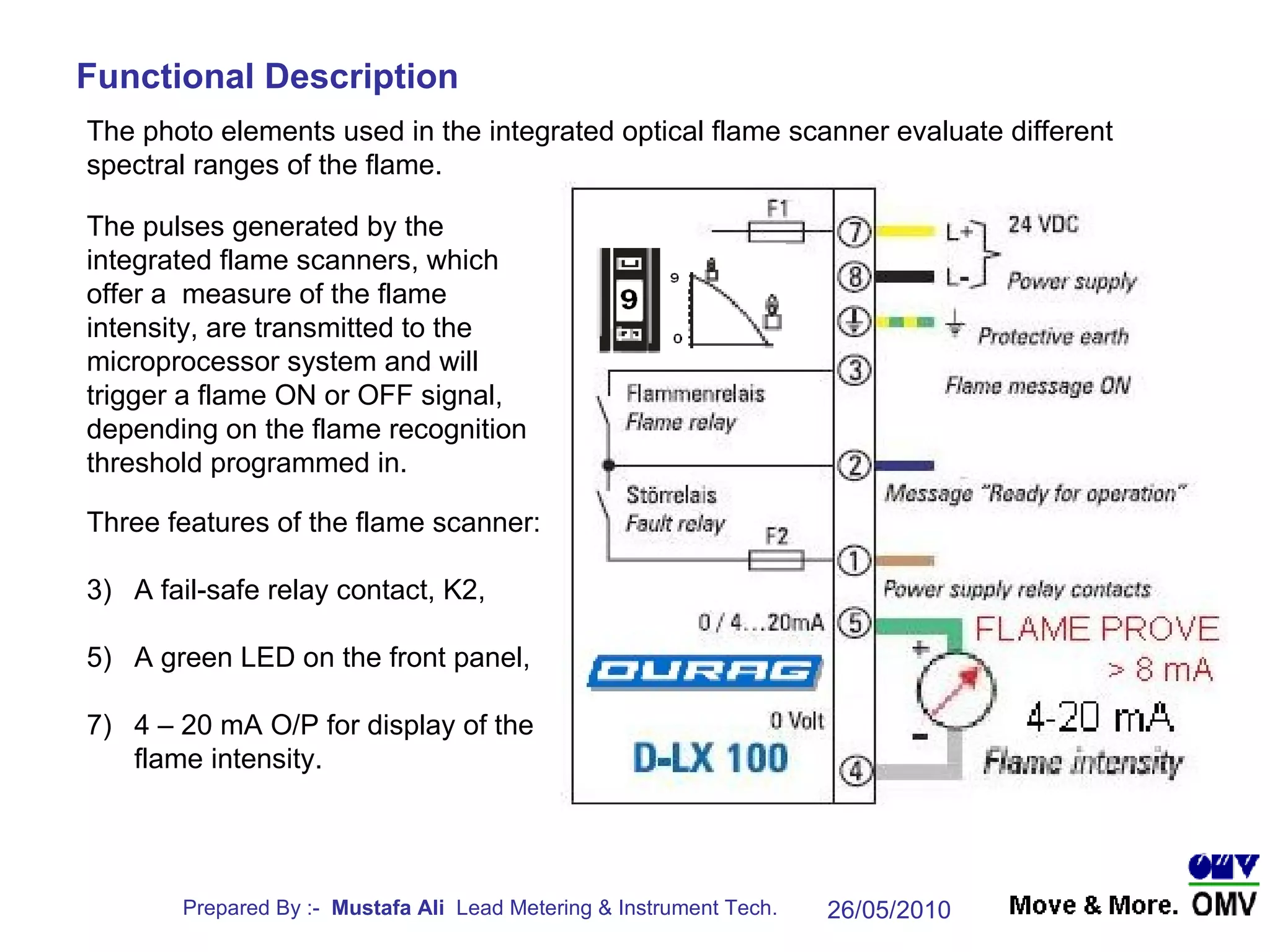

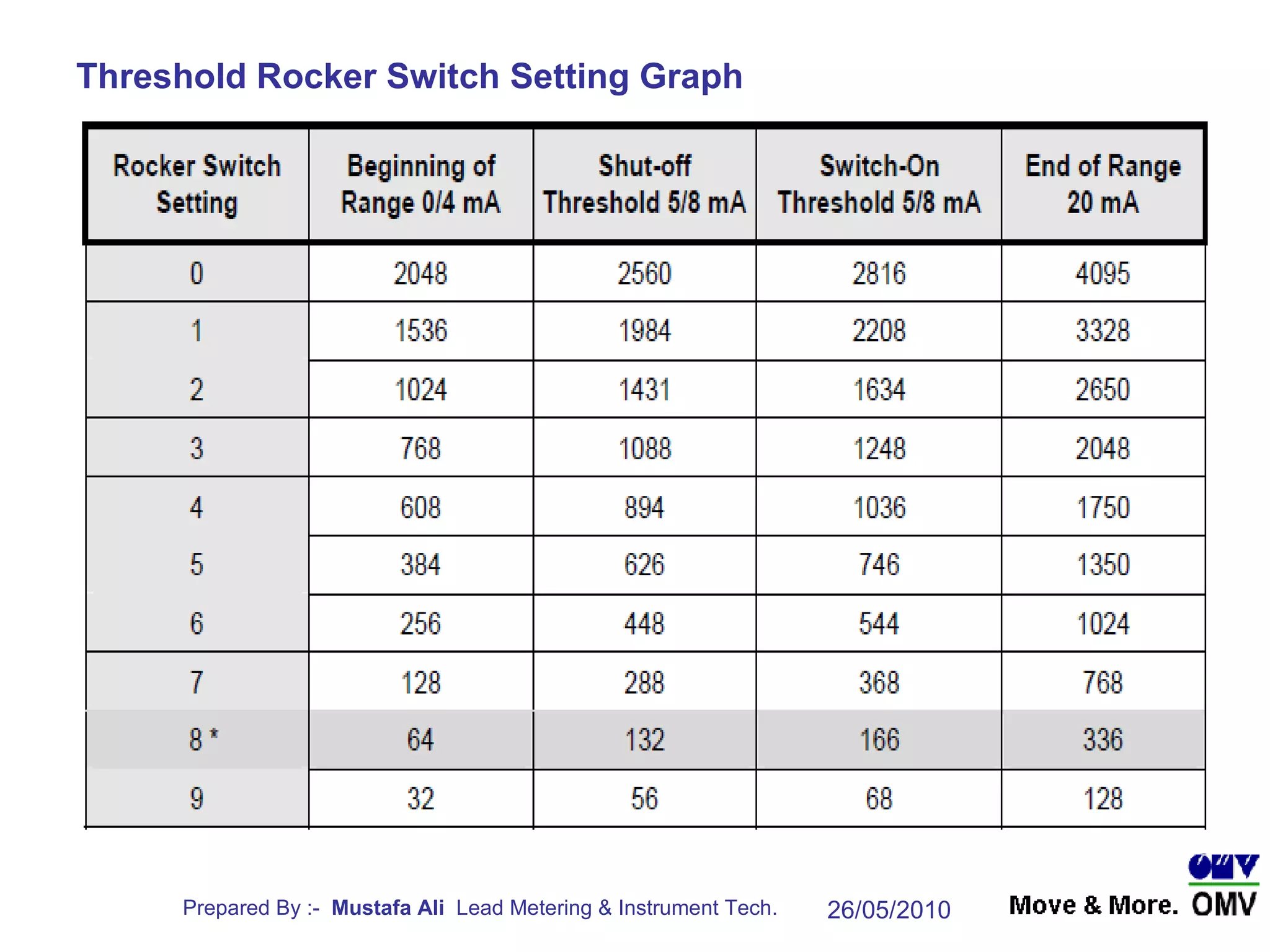

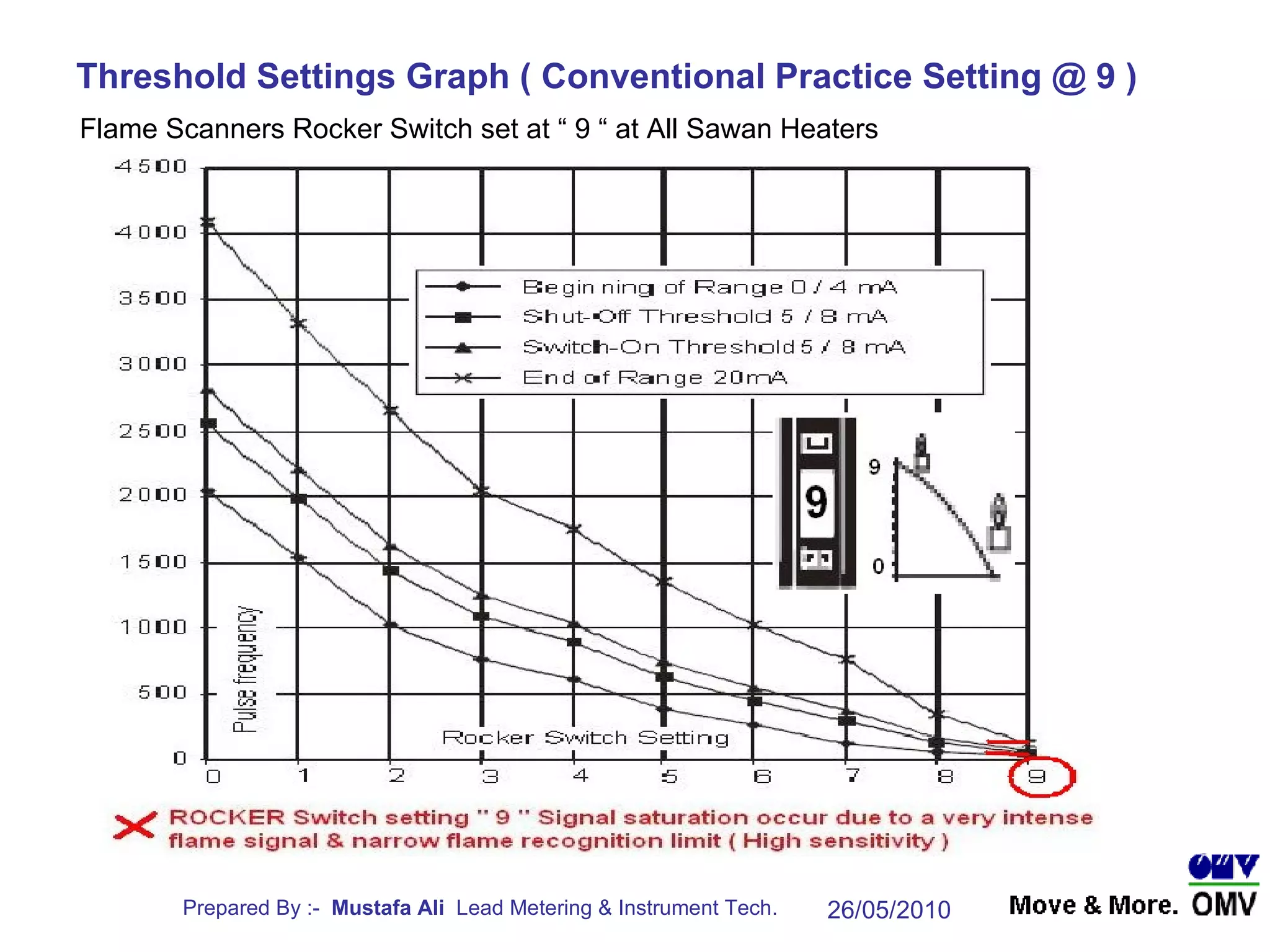

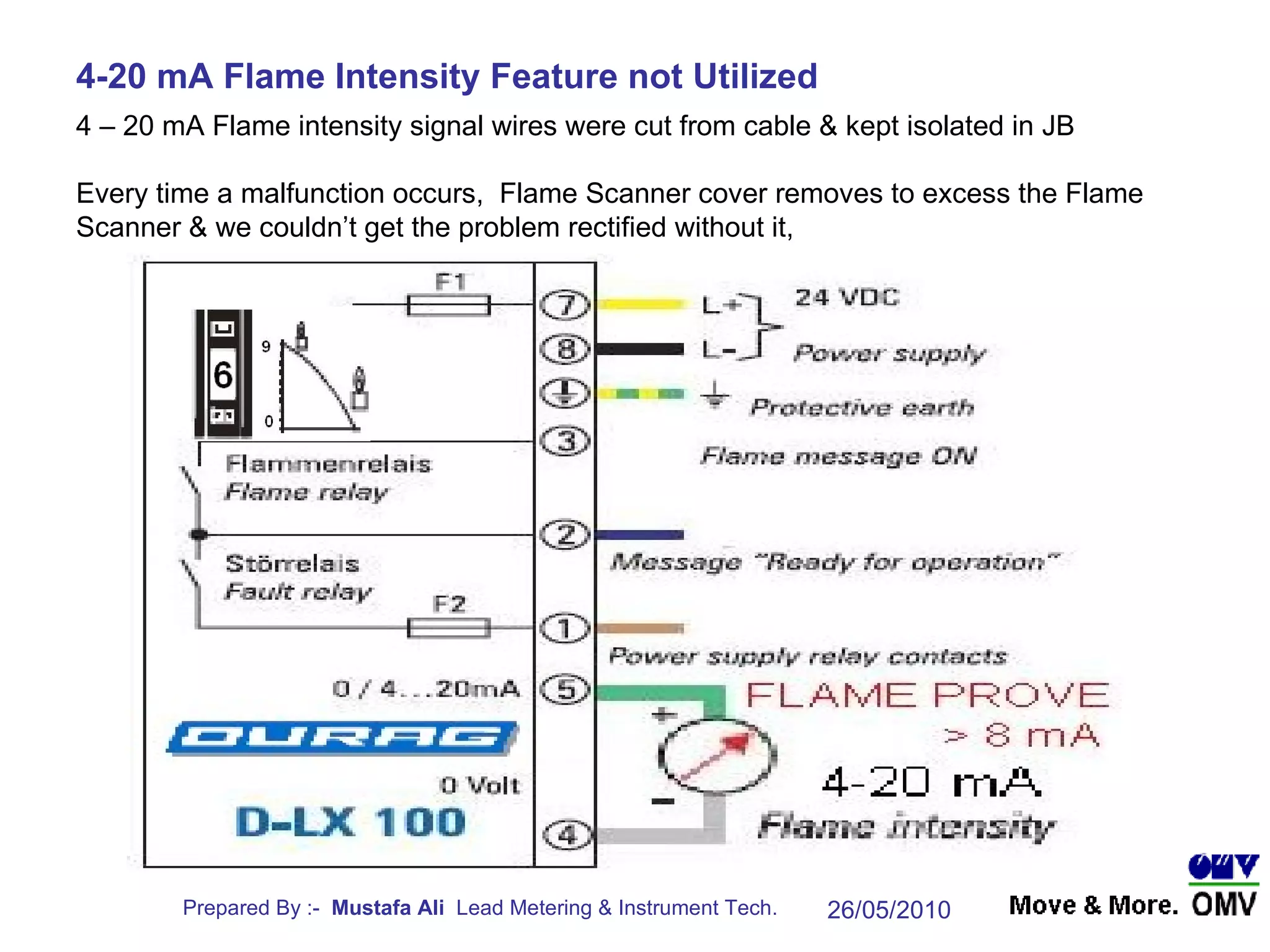

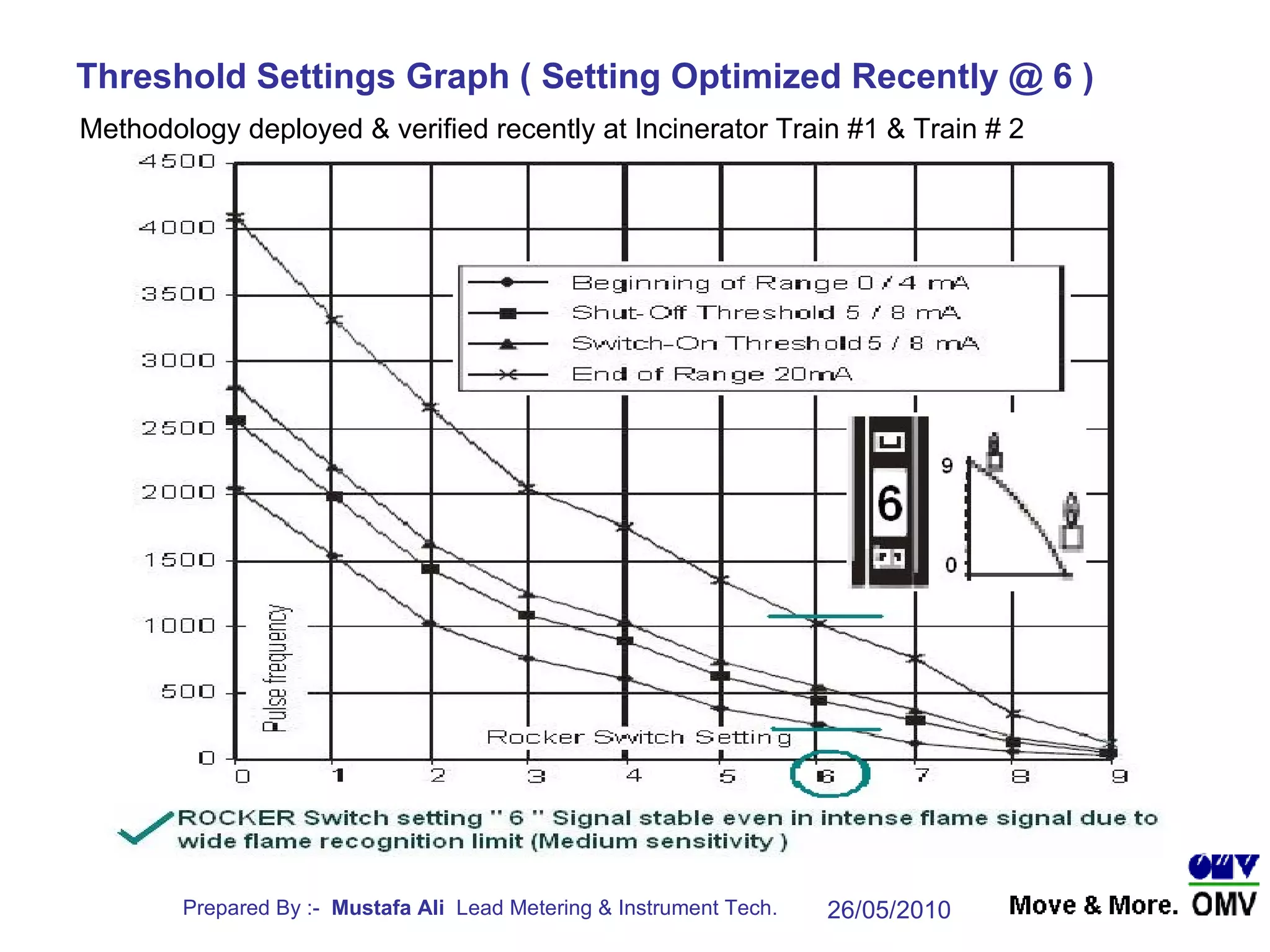

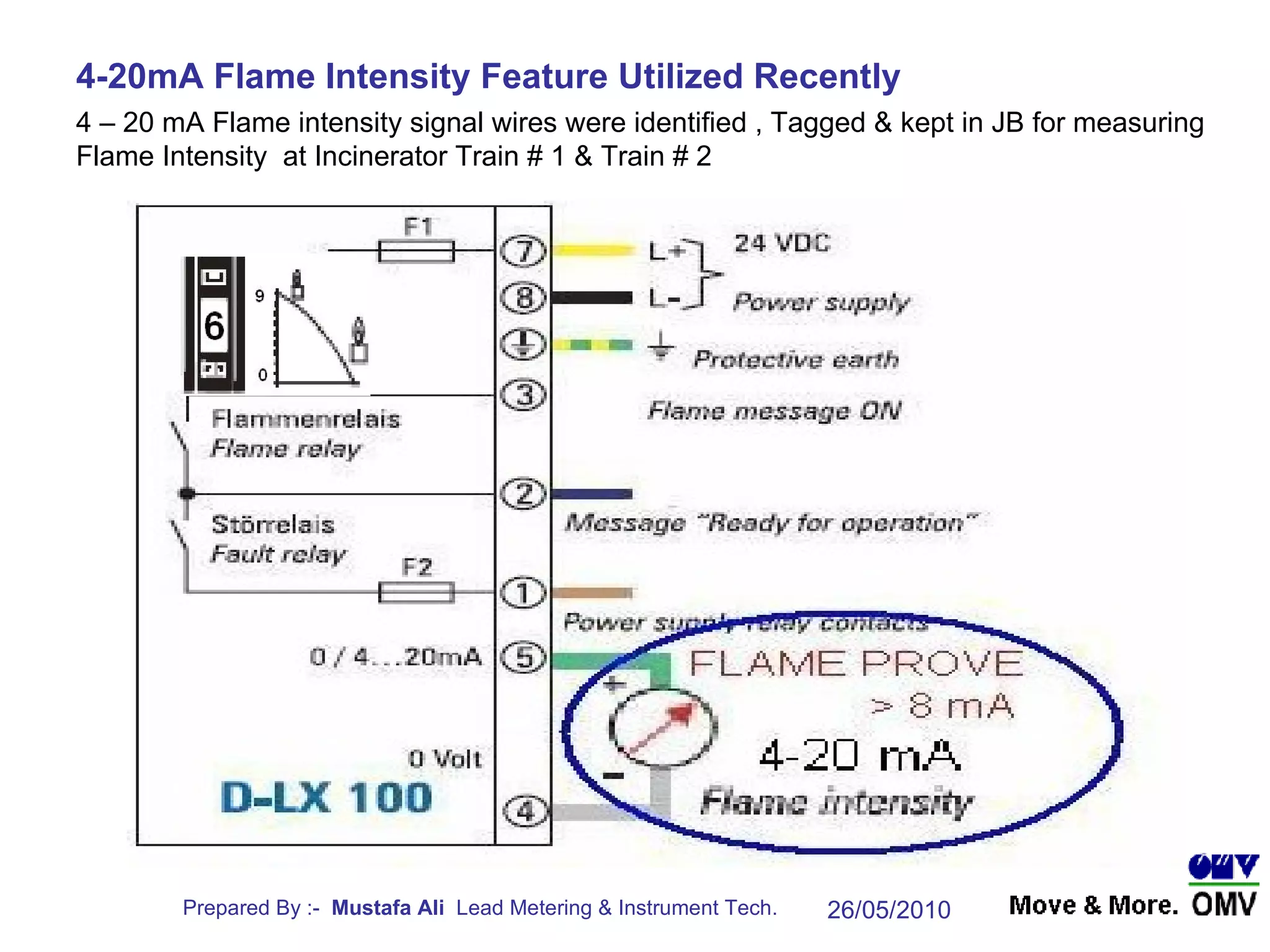

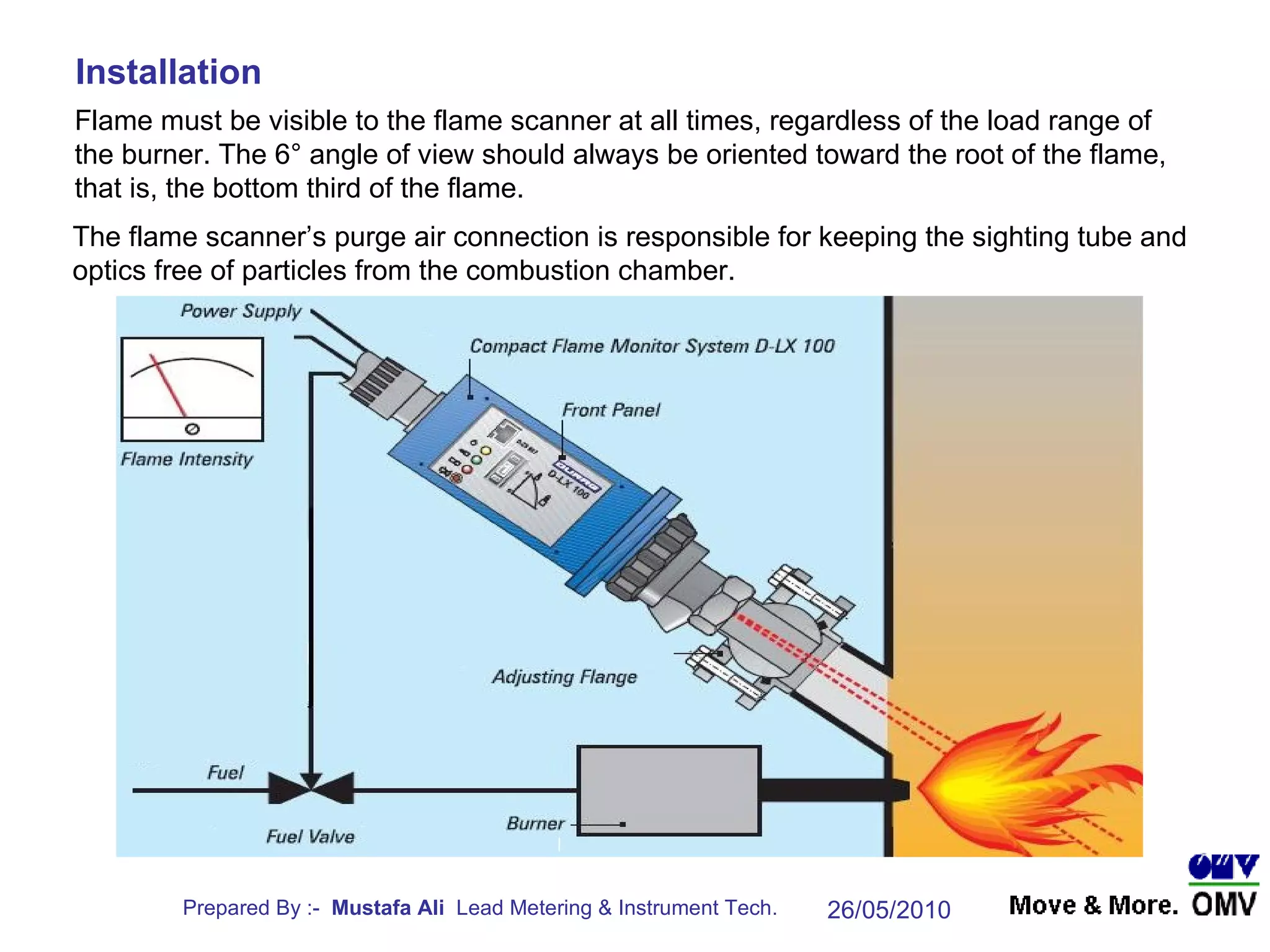

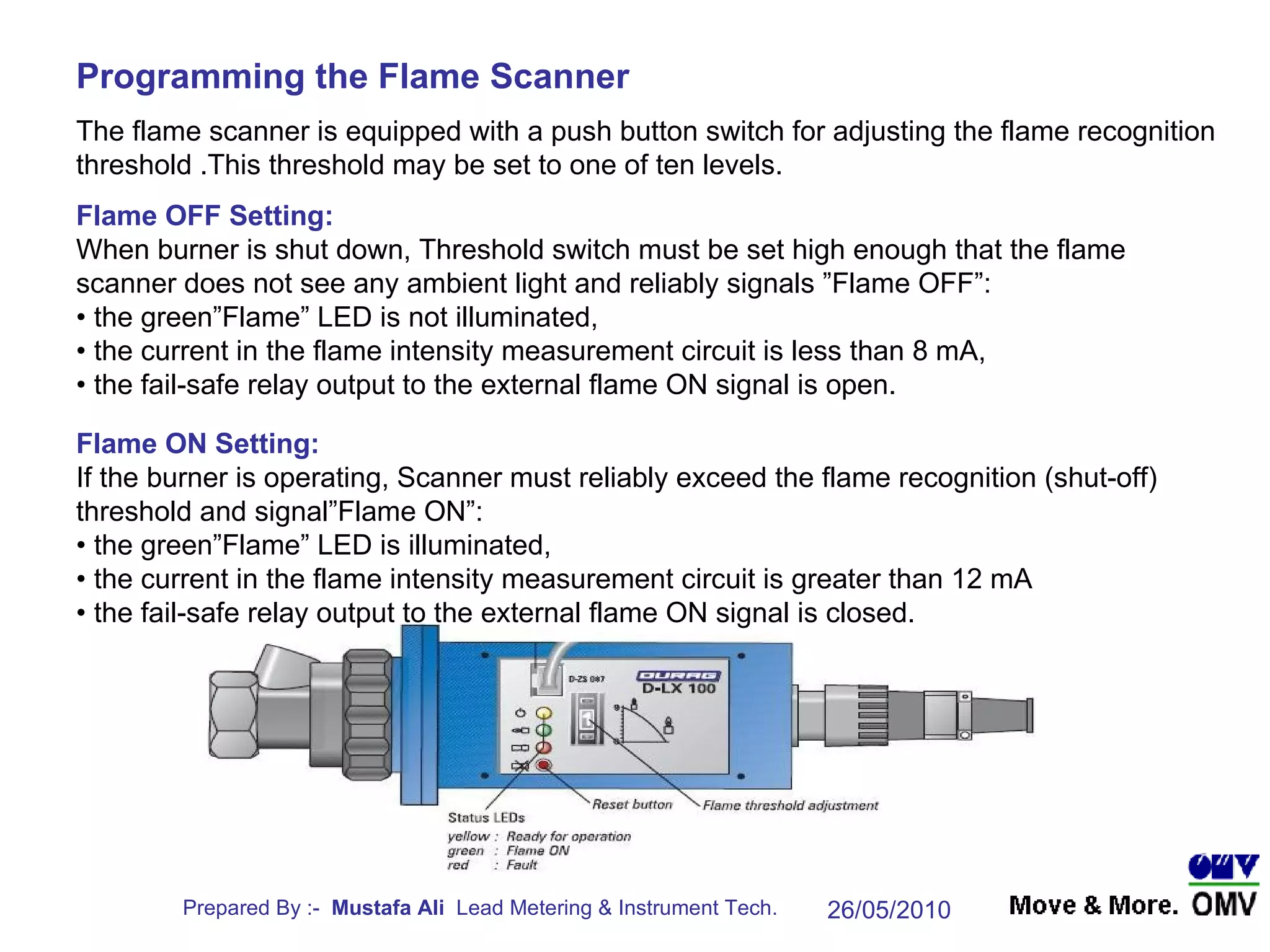

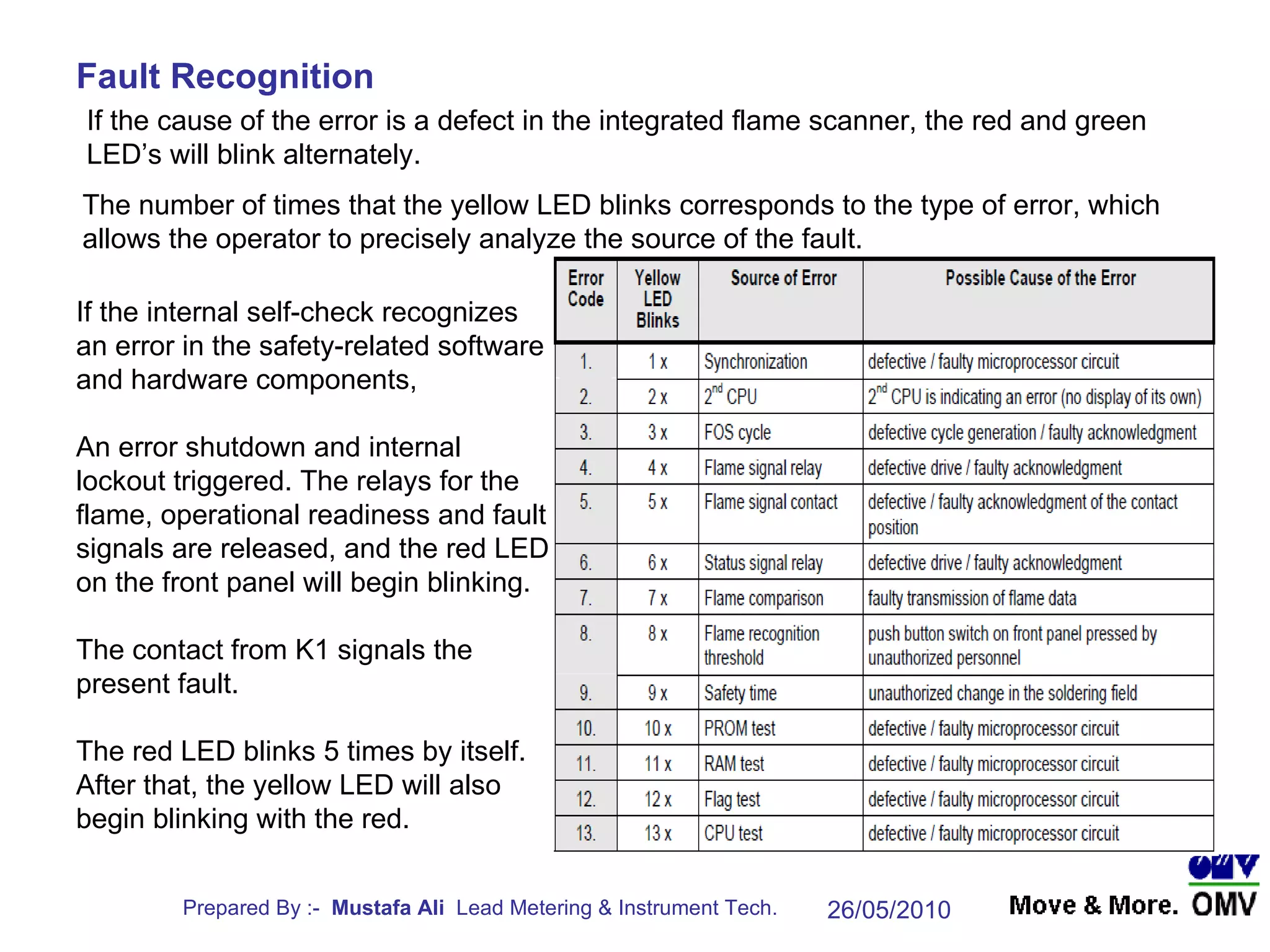

Flame scanners are critical for monitoring flame intensity in heaters, particularly in gas and oil combustion systems, ensuring safe operation. The document discusses the optimization of flame scanner settings, adjusting sensitivity from 9 to 6 to improve functionality and reduce malfunctions during heater startups. Recommendations for maintaining effective flame detection include proper installation and programming of flame scanners to reliably differentiate between flame on and off states.