Retire the PDCA wedge

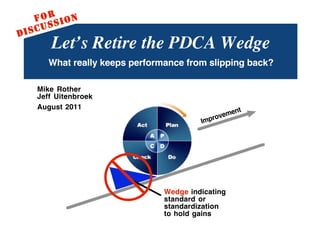

- 1. F O RS I O N S D I SCU Let’s Retire the PDCA Wedge What really keeps performance from slipping back? Mike Rother Jeff Uitenbroek August 2011 nt roveme Imp Wedge indicating standard or standardization to hold gains Mike Rother RETIRE THE PDCA WEDGE? 1

- 2. SOMETHING TO THINK ABOUT Dear Lean Community, We may have a bug in our programming, which is hampering our efforts to achieve continuous improvement. The PDCA wedge may be a creation of an occasional-improvement mindset, which allows for backsliding between events, instead of a mindset of continually improving and learning. Mike Rother RETIRE THE PDCA WEDGE? 2

- 3. IS THE PDCA WEDGE BASED ON A MISCONCEPTION? There is a popular concept that we can utilize standards to maintain a process condition. Such standards are often depicted graphically as a wedge that prevents the process from backsliding. However, it is generally not possible simply to maintain a level of process performance. Process performance tends to degrade no matter what, even if a standard is defined, explained to everyone, posted and regularly audited. This is not because of poor discipline, but due to interaction effects and entropy, which say that any organized process naturally tends to decline to a chaotic state if we leave it alone. Where did the wedge concept come from? Mike Rother RETIRE THE PDCA WEDGE? 3

- 4. ITʼS PROBABLY NOT FROM DEMING In the “Act” part of the PDSA cycle, Deming talks about “adopting the change.” That is, if a solution or countermeasure has been successfully tested you might decide to make it permanent. Deming seems to be talking about standardizing not to prevent slipping back, but simply in regard to putting a tested countermeasure into place. Deming makes a different statement on the topic of not slipping back: you have to keep turning the PDCA wheel. To maintain gains and uniformity, you have to keep improving. “Continue the cycle, over and over, with never-ending improvement of quality, at lower and lower cost.” ~ W. Edwards Deming, Out of the Crisis, p181 “Quality of a product does not necessarily mean high quality. It means continual improvement of the process, so that the consumer may depend on the uniformity of a product and purchase it at a low cost.” ~ W. Edwards Deming, 1980 Mike Rother RETIRE THE PDCA WEDGE? 4

- 5. ITʼS PROBABLY NOT FROM TOYOTA The Toyota way of thinking about many standards is that they are more like something you are striving to achieve. The standard itself doesnʼt make anything happen. Itʼs a definition of where you want to be. Standard Standard Actual Actual A “standard” is a description “Standardized work” means, in of how a process should essence, that a process is operate. Itʼs the intended, actually operating as specified normal pattern. by the standard. Consider this: Toyota is achieving quality excellence not because processes are done the same way each time, but because Toyota is striving to achieve the target condition of processes being done the same way each time. Itʼs a subtle but important distinction. Mike Rother RETIRE THE PDCA WEDGE? 5

- 6. WEDGE WAY versus TOYOTA WAY Wedge thinking Toyota thinking When an abnormality occurs When an abnormality occurs Weʼre slipping We arenʼt back there yet What is preventing We need us from reaching the to maintain target condition? The operators Management is are responsible responsible We need more What is the discipline! next step? In the wedge way of looking The Toyota way of thinking at it we think an abnormality turns this around: the means weʼre slipping back, abnormality means we have and itʼs someoneʼs fault. not yet have reached the target condition. There are still obstacles. Illustration from Toyota Kata, page 115 Mike Rother RETIRE THE PDCA WEDGE? 6

- 7. WHY DID WE COME UP WITH THE WEDGE CONCEPT? One reason may be that we think in terms of improvement projects (start, stop, move on), which leads us to an audit & compliance mindset. This thinking may in turn be based on a desire for certainty and misunderstanding of what is ʻscientific.ʼ • Quantification and precision What we • Objective and certain may think scientific is • Reveals what is there Eg: a standard is definitive • Involves uncertainty, ambiguity & incompleteness What scientific • Never free from error really is • A process of discovery, via systematic trial and error Eg: a standard is a hypothesis Mike Rother RETIRE THE PDCA WEDGE? 7

- 8. WE NEED A STANDARD, OF COURSE Thereʼs no genie who, without us defining the desired standard, is going to make processes work in a way that serves customers with highest quality and lowest cost. But, likewise, just because weʼve defined a standard does not cause a genie to appear and make things so and hold entropy at bay. So a process needs a standard. But how does it work? Mike Rother RETIRE THE PDCA WEDGE? 8

- 9. A STANDARD IS LIKE A TARGET CONDITION A standard is an idea of where you want to be ent rovem Imp Itʼs here! The standard is not here Rather than a backstop, a standard is something you aspire to. Just waiting for deviations and abnormalities and then reacting to them is not enough. Without something to strive for, entropy will set in no matter what you do. Mike Rother RETIRE THE PDCA WEDGE? 9

- 10. BOTTOM LINE Thereʼs no steady state The point is that any process is either slipping back or being improved, and the best and perhaps only way to prevent slipping back is to keep trying to move forward - every process every day - even if only in small steps. The best way to sustain results is to make improvement toward your vision part of normal daily activity. Fortunately, striving toward a target condition is highly motivating, brings a team together and can be a lot of fun. Mike Rother RETIRE THE PDCA WEDGE? 10

- 11. SO LETʼS RETIRE THE WEDGE Itʼs a lifelong process of striving, for which we are well equipped. We can practice, learn and teach a fundamental way (a kata) for meeting challenging target conditions along uncertain paths. Mike Rother RETIRE THE PDCA WEDGE? 11