Milling machine MACHINE SHOP

•Download as PPTX, PDF•

0 likes•116 views

Milling machine MACHINE SHOP

Report

Share

Report

Share

Recommended

More Related Content

What's hot

What's hot (20)

Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECH

Milling machine-types-operations..etc..from L.NARAYANAN,M.E.,AP.MECH

Similar to Milling machine MACHINE SHOP

Similar to Milling machine MACHINE SHOP (20)

Mechanical Technology Grade 12 Chapter 6 Terminology Of Machines

Mechanical Technology Grade 12 Chapter 6 Terminology Of Machines

MILLING MACHINE PPT 2: PARTS AND CLASSIFICATION OF MILLING MACHINES

MILLING MACHINE PPT 2: PARTS AND CLASSIFICATION OF MILLING MACHINES

More from GLA UNIVERSITY MATHURA

More from GLA UNIVERSITY MATHURA (20)

Vcrs Vars ( vapour compression refrigeration cycle)

Vcrs Vars ( vapour compression refrigeration cycle)

Recently uploaded

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

Booking Contact Details

WhatsApp Chat: +91-7001035870

Nagpur Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts Nagpur understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

27-april-2024(v.n)

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur EscortsCall Girls in Nagpur High Profile

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...Call Girls in Nagpur High Profile

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Call Girls Service Nagpur Tanvi Call 7001035870 Meet With Nagpur Escorts

Booking Contact Details

WhatsApp Chat: +91-7001035870

Nagpur Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts Nagpur understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

27-april-2024(v.n)

Call Girls Service Nagpur Tanvi Call 7001035870 Meet With Nagpur Escorts

Call Girls Service Nagpur Tanvi Call 7001035870 Meet With Nagpur EscortsCall Girls in Nagpur High Profile

Recently uploaded (20)

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Meera Call 7001035870 Meet With Nagpur Escorts

(PRIYA) Rajgurunagar Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...![(PRIYA) Rajgurunagar Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![(PRIYA) Rajgurunagar Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

(PRIYA) Rajgurunagar Call Girls Just Call 7001035870 [ Cash on Delivery ] Pun...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

High Profile Call Girls Nagpur Isha Call 7001035870 Meet With Nagpur Escorts

High Profile Call Girls Nagpur Isha Call 7001035870 Meet With Nagpur Escorts

UNIT-V FMM.HYDRAULIC TURBINE - Construction and working

UNIT-V FMM.HYDRAULIC TURBINE - Construction and working

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Call Girls Service Nagpur Tanvi Call 7001035870 Meet With Nagpur Escorts

Call Girls Service Nagpur Tanvi Call 7001035870 Meet With Nagpur Escorts

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

result management system report for college project

result management system report for college project

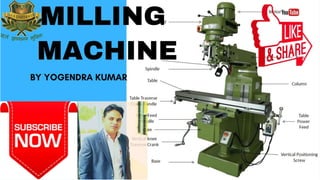

Milling machine MACHINE SHOP

- 2. What is Milling Machine? It is a machine which is used to remove metals from the workpiece with the help of a revolving cutter called milling cutter. It is used to machined the flat, rough and irregular surfaces and this is done by feeding the workpiece against a rotating milling cutter.

- 3. PARTS OF MILLING MACHINE 1. Column & Base Column including base is the main casting that supports all other parts of milling machine. The column contains an oil reservoir and a pump which lubricates the spindle. The column rests on the base and base contains coolant reservoir and a pump which is used during machining operation that requires coolant. 2. Knee It is a casting that supports the saddle and table. All gearing mechanism is enclosed within the knee. It is fastened to the column by dovetail ways. The knee is supported and adjusted by a vertical positioning screw (elevating screw). The elevating screw is used to adjust the knee up and down by raising or lowering the lever either with the help of hand or power feed.

- 4. 3. Saddle and Swivel Table The saddle is present on the knee and supports the table. It slides on a horizontal dovetail on the knee and dovetail is parallel to the axis of the spindle ( in horizontal milling m/c). The swivel table (in universal machines only) is attached to the saddle that can be swiveled (revolved) horizontally in either direction. 4. Power Feed Mechanism It is the knee which contains the power feed mechanism. It is used to control the longitudinal ( left and right), transverse ( in and out) and vertical (up and down) feeds. To get the desired rate of feed on the machine, the feed selection lever is positioned as indicated on the feed selection plates. On some universal knee and column milling machine, the feed is obtained by turning the speed selection handle until the desired rate of feed is indicated on the feed dial. Most of the milling machines have a rapid traverse lever that can be engaged when a temporary increase in the speed of the longitudinal, transverse or vertical feeds is required. For example this lever would be engaged when the operator is positioning or aligning the work.

- 5. 5. Table It is a rectangular casting which is present on the top of the saddle. It is used to hold the work or work holding devices. It contains several T-slots for holding the work and work holding devices (i.e. jigs and fixtures). The table can be operated by hand or by power.To move the table by hand, engage and turn the longitudinal hand crank. To move it through power, engage the longitudinal direction feed control lever. 6. Spindle It is the shaft that is used to hold and drives the cutting tools of the milling machine. The spindle is mounted on the bearings and supported by the column. Spindle is driven by the electric motor through gear trains. The gear trains are present within the column. The face of the spindle which lies near to the table has an internal taper machined on it. The internal taper at the front face of the spindle permits only a tapered cutter holder or arbor. It has two keys at the front face which provides a positive drive for the cutter holder or arbor. The drawbolt and jam nut is used to secure the holder and arbor in the spindle.

- 6. 7. Over Arm / Overhanging Arm It is a horizontal beam present at the top face of the column. It may be a single casting which slides on the dovetail ways present on the top face of the column. The overarm is used to fastened arbor support. It may consist of one or two cylindrical bars which slide through the holes in the column. 8. Arbor Support It is a casting with bearing that supports the outer end of the arbor. It also helps in aligning the outer end of the arbor with the spindle. It prevents the springing of outer end of the arbor during cutting operations. There are generally two types of arbor supports used in the milling machine. The first one has small diameter bearing hole, 1-inch in maximum diameter. And the other one has large diameter bearing hole, usually upto 23/4 inches. The arbor support has an oil reservoir that lubricates the bearing surfaces. It can be clamped anywhere on the overarm. The arbor support is used only in the horizontal types of milling machine.

- 7. 9. Ram The overhanging arm in the vertical machine is called ram. One end of the ram is mounted on the top of the column and on the other end milling head is attached. The ram can be a moved transversally ( in and out) on the column by a hand lever.