Introduction to Civil Engg. Unit-IV.pdf

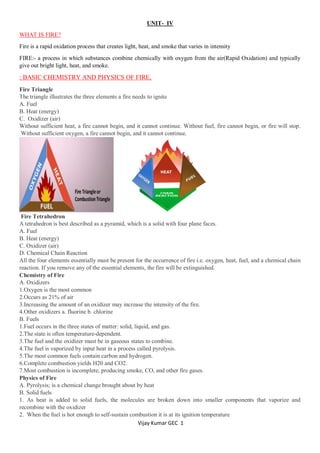

- 1. Vijay Kumar GEC 1 UNIT- IV WHAT IS FIRE? Fire is a rapid oxidation process that creates light, heat, and smoke that varies in intensity FIRE:- a process in which substances combine chemically with oxygen from the air(Rapid Oxidation) and typically give out bright light, heat, and smoke. : BASIC CHEMISTRY AND PHYSICS OF FIRE, Fire Triangle The triangle illustrates the three elements a fire needs to ignite A. Fuel B. Heat (energy) C. Oxidizer (air) Without sufficient heat, a fire cannot begin, and it cannot continue. Without fuel, fire cannot begin, or fire will stop. Without sufficient oxygen, a fire cannot begin, and it cannot continue. Fire Tetrahedron A tetrahedron is best described as a pyramid, which is a solid with four plane faces. A. Fuel B. Heat (energy) C. Oxidizer (air) D. Chemical Chain Reaction All the four elements essentially must be present for the occurrence of fire i.e. oxygen, heat, fuel, and a chemical chain reaction. If you remove any of the essential elements, the fire will be extinguished. Chemistry of Fire A. Oxidizers 1.Oxygen is the most common 2.Occurs as 21% of air 3.Increasing the amount of an oxidizer may increase the intensity of the fire. 4.Other oxidizers a. fluorine b. chlorine B. Fuels 1.Fuel occurs in the three states of matter: solid, liquid, and gas. 2.The state is often temperature-dependent. 3.The fuel and the oxidizer must be in gaseous states to combine. 4.The fuel is vaporized by input heat in a process called pyrolysis. 5.The most common fuels contain carbon and hydrogen. 6.Complete combustion yields H20 and CO2. 7.Most combustion is incomplete, producing smoke, CO, and other fire gases. Physics of Fire A. Pyrolysis; is a chemical change brought about by heat B. Solid fuels 1. As heat is added to solid fuels, the molecules are broken down into smaller components that vaporize and recombine with the oxidizer 2. When the fuel is hot enough to self-sustain combustion it is at its ignition temperature

- 2. Vijay Kumar GEC 2 3. The size, arrangement, continuity and moisture content of the solid fuel can affect the rate of pyrolysis c. Liquid fuels 1.Factors affecting liquid fuels a. Flow like water but do not readily separate b. Specific Gravity: c. Boiling Point: when the vapor pressure equals atmospheric pressured. d. Volatility: the ease at which the liquid gives off vapors at ambient temperatures. Flash Point: the minimum temperature at which a liquid gives off vapors sufficient to forman ignitable mixture with air f. Miscibility: the ability of the liquid to mix with water Gaseous fuels 1.Tend to expand indefinitely 2.Flammable Limits/Flammable Range: the fuel mixture can be too rich or too lean to burn 3.Classification: flammable or nonflammable 4.Some nonflammable gases support combustion: oxygen is an example 5.Flammable vapors are not always visible Extinguishing Agent means a source of extinguishment in which to quickly and effectively suppress the fire Heat and Temperature A. Sources of heat energy: 1.Chemical 2.Mechanical 3.Electrical Heat Transfer Three methods of heat transfer: 1.Conduction: through a medium without visible motion 2.Convection: through a circulating medium (liquid or gas) 3.Radiation:by wavelengths of energy .Direct Flame Contacts a combination of the three methods of heat transfer as objects are bathed in flames Classification of Fires A. Class A: ordinary combustibles B. Class B: flammable liquids (gases) C. Class C: energized electrical equipment D. Class D: flammable metals E. Class K: cooking materials (cooking oils/fats/grease) Stages/Phases of Fire A. Incipient stage: oxygen at 21%, flame temperature 180 degrees F –220 degrees F. The heat has not spread to other fuels nearby B. Growth stage: early stage of a fire; availability of fuel and oxygen is unlimited. Characterized by rapid increase of heat (temperature) C. Fully Developed: energy release is at a maximum rate and limited only by the availability of fuel and/or oxygen D. Decay: when much of the fuel has been consumed, the energy being released has diminished, and the temperature decreases. In this stage, the fire goes from ventilation-controlled to fuel-controlled Life cycle of fire The six elements of the life cycle of fire are 1. input heat, 2. fuel, 3. oxygen, 4. proportioning, 5. mixing, 6. ignition continuity. All of these elements are essential for both the initiation and continuation of the diffusion flame combustion process. RECOGNITION OF POSSIBLE FIRE SOURCES Fires need three things to start

- 3. Vijay Kumar GEC 3 1. A SOURCE OF IGNITION (HEAT), 2. SOURCE OF FUEL (SOMETHING THAT BURNS) AND 3. SOURCE OF OXYGEN: SOURCES OF IGNITION INCLUDE 1. Electric spark and electric wire short circuit 2. Naked flames- welding, burner, cutting torch 3. Malfunctioning ,failure of electrical equipment and system , 4. Smokers’ materials (cigarettes, matches etc.), 5. Hot surface, 6. Hot Engine, 7. Anything else that can get very hot or cause sparks; 8. Lightning strike, 9. Trash Containers 10. Spontaneous Heating 11. Heaters, Boiler, ovens/ blast furnace 12. Open fire 13. Electrostatic spark 14. Sun 15. Smoking SOURCES OF FUEL INCLUDE 1. LIQUID: gasoline, petrol, diesel, kerosene, LPG, motor oil, cleaning solvents, paints (oil base), linseed oil, mineral oil 2. Chemical,;- acetone, ether, pentane, toluene, diethyl ether, alcohols, benzene, ethanol petroleum ether 3. SOLID; wood, paper, plastic, rubber or foam, loose packaging materials, waste rubbish and furniture, cloth. metallic sodium and potassium, oily fabrics, processed metals, Aluminum powder, Camphor, Magnesium Matches, Naphthalene, Nitrocellulose Phosphorus,Sulfur 4. GASES ;- propane, hydrogen, butane, methane, ethylene, acetylene, ammonia, ethane silane ammonia, carbon monoxide. hydrogen cyanide, hydrogen chloride, and acrolein. SOURCES OF OXYGEN INCLUDE THE AIR AROUND US.

- 4. Vijay Kumar GEC 4 EMERGENCY PROCEDURES IN THE EVENT OF A FIRE, 1. Be Calm and Act Quickly 2. Close the Immediate Door 3. Activate the Fire Alarm 4. Warn Others of the Danger 5. Cover Your Nose If There is Smoke 6. Use Fire Extinguisher or Smother Blanket 7. Switch of Electricity and Gas Supply 8. Exit the Building 9. Do Not Re-enter the Building 10. Call for HelpIf the fire is out of control and a danger, do not attempt to put it out, evacuate the building immediately 11. Assist injured personnel or notify emergency responders of the medical emergency. 12. Exit the building following emergency maps. 13. Assist physically impaired individuals to a secure area and notify emergency responders. 14. Ensure all personnel are out of the building. FIRE CLASSIFICATION Class A Fires—Fires involving solid combustible materials of organic nature such as wood, paper, rubber, plastics, etc, where the cooling effect of water is essential for extinction of fires. Class B Fires—Fires involving flammable liquids or liquefiable solids or the like where a blanketing effect is essential. Class C Fires—Fires involving flammable gases under pressure including liquified gases, where it is necessary to inhibit the burning gas at fast rate with an inert gas, powder or vaporizing liquid for extinguishment.

- 5. Vijay Kumar GEC 5 Class D Fires—Fires involving combustible metals, such as magnesium, aluminium, zinc, sodium, potassium, etc, when the burning metals are reactive to water and water containing agents and in certain cases carbon dioxide, halogenated hydrocarbons and ordinary dry powders. These fires require special media and techniques to extinguish. FIRE EXTINGUISHING AGENTS A fire extinguishing agent is a product used to extinguish a fire. 1. Dry Chemical. 2. Wet Chemical. 3. Clean Agent. 4. Water Stream (extinguisher). 5. Water Mist (extinguisher). 6. Foam. 7. Dry Powder. 8. Carbon di oxide Dry Chemical. This agent is made up of very small particles of sodium bicarbonate, potassium bicarbonate, or ammonium phosphate with additives to help enhance flow and prevent packing and caking. Interrupts chemical reactions . Dry Chemical fire extinguishers extinguish the fire primarily by interrupting the chemical reaction of the fire triangle. This agent also works by creating a barrier between the oxygen element and the fuel element on Class A fires. Today’s most widely used type of fire extinguisher is the multipurpose dry chemical that is effective on Class A, B, and C fires. Wet Chemical Wet Chemical is an agent that extinguishes the fire by removing the heat of the fire triangle and prevents re-ignition by creating a barrier between the oxygen and fuel elements. Wet chemical of Class K extinguishers were developed for modern, high efficiency deep fat fryers in commercial cooking operations. Some may also be used on Class A fires in commercial kitchens. Clean Agent

- 6. Vijay Kumar GEC 6 Clean Agent – Halogenated or Clean Agent extinguishers include the halon agents as well as the newer and less ozone depleting halocarbon agents. The currently acceptable clean agents used in extinguishers include halocarbons, such as Halotron I and FE36, Halon 1211, and carbon dioxide They extinguish the fire by interrupting the chemical reaction of the fire triangle. Clean agent extinguishers are primarily for Class B & C fires. Some larger clean agent extinguishers can be used on Class A, B, and C fires. Water Stream (extinguisher). This is an extinguisher with a 2.5 gallon capacity, containing tap water or a loaded stream charge that is discharged through a hose as a solid stream. Removes heat Water Mist – Water Mist – Water Mist extinguishers are a recent development that extinguishes the fire by taking away the heat element of the fire triangle. Removes heat They are an alternative to the clean agent extinguishers where contamination is a concern. Water mist extinguishers are primarily for Class A fires, although they are safe for use on Class C fires as well. Foam Extinguishers containing foam solution have a hose with a special nozzle that introduces air to the solution, which creates foam as it leaves the extinguisher. Water and Foam fire extinguishers extinguish the fire by taking away the heat element of the fire triangle. Foam agents also separate the oxygen element from the other elements. Water extinguishers are for Class A fires only – they should not be used on Class B or C fires. Dry powder This extinguishing agent is made up of powder or granular particles that are intended for the extinguishment fires. Typical dry powder agents include sodium chloride graphite, and copper, Dry Powder extinguishers are similar to dry chemical except that they extinguish the fire by separating the fuel from the oxygen element or by removing the heat element of the fire triangle. However, dry powder extinguishers are for Class D or combustible metal fires, only. They are ineffective on all other classes of fires Carbon Dioxide Carbon Dioxide – Carbon Dioxide fire extinguishers extinguish fire by taking away the oxygen element of the fire triangle and also be removing the heat with a very cold discharge. Reduces oxygen to less than 15% Carbon dioxide can be used on Class B & C fires. They are usually ineffective on Class A fires. FIRE FIGHTING SYSTEM DIRECT ATTACK

- 7. Vijay Kumar GEC 7 A method whereby the fire is attacked immediately adjacent to the burning fuel. If you apply water directly onto the burning materials, you are conducting a direct attack. where personnel and resources work at, or very close to, the burning edge of the fire. Firefighting crews aggressively attack the fire either by applying water or extinguishing the fire using 'hand tools' and 'beaters‘ INDIRECT ATTACK TECHNIQUE A method of suppression in which the control line is located some considerable distance away from the fire's active edge. In this method of attack, the fuel is separated from the path of the approaching fire. When heat or other conditions deny access to space. May improve condition to permit reentry for direct attack. This technique is usually applied on high-intensity fires where fire fighters cannot approach the front of the fire due to heat and/or smoke conditions If you are applying water into the compartment to achieve cooling of the environment or to bank the stream into the area, you are using an indirect attack. Generally done in the case of a fast-spreading or high-intensity fire and to utilize natural or constructed firebreaks or fuel breaks and favorable breaks in the topography. The Combination Attack Technique The combination attack uses both the direct and indirect techniques in combating fire at the same time. In this method, the direct attack here is used to attack the fire itself while the aspect of the indirect attack combats the gases that are overhead. Uses indirect to cool atmosphere, then direct to extinguish Only use enough water to control the fire. These two methods both ensure that fire is extinguished quickly and the risk of it spreading is minimized. 1. Standpipe and hose systems 2. Automatic Sprinkler Systems 3. Foam / Chemical Suppression 4. Gaseous Fire Suppression 5. portable fire extinguisher 6. Robotic fire fighting 7. UAV / Drone fire fighting Standpipe and hose systems Standpipe and hose systems in buildings allow the occupants or fire service personnel to suppress a fire without further help. Standpipe systems are an arrangement of piping, valves, hose connections, and related equipment installed in a building in a fixed manner. The systems may or may not have hoses permanently attached. Water supplies may or may not be continually provided to standpipe systems. Fire department personnel trained in manual fire suppression methods are the ones who primarily use standpipe systems. Many standpipe systems no longer have occupant hoselines (small diameter 1-1/2 inch). The fixed piping of a standpipe system in a building allows the fire service to connect its hoselines into a pressurized water source near the fire floor. Water Supplies;municipal or private water mains,gravity tanks,pressure tanks,fire pumps. Wet Pipe Systems Wet pipe sprinkler systems are the most common form of fire sprinkler. Wet pipe systems use closed automatic sprinklers attached to a piping system containing water under pressure at all times. This is the traditional type of fire sprinkler where the sprinkler pipes are filled with pressurized water that will immediately discharge when a fire occurs. When the temperature at the ceiling gets hot enough the glass bulb or fusible link in a sprinkler will break . Wet pipe sprinkler systems are the most reliable and cost effective. Dry Pipe Systems Dry pipe systems are very similar to wet pipe systems with one major difference. The pipe is not constantly filled with water. Instead, the water is held behind a dry pipe valve usually some distance away from where the sprinklers are located. Like a wet pipe system, when the temperature at the ceiling becomes hot enough, the glass bulb or fusible link of the sprinkler breaks. However, in this case, water isn’t immediately available because the pipe is not water filled. Instead, air is released from the now open sprinkler head. This creates a drop in pressure causing the dry pipe valve to open and water to fill the system. Water will then flow from the open sprinkler head. Pre action systems

- 8. Vijay Kumar GEC 8 employ closed automatic sprinklers attached to a piping system which contains air, which may or may not be under pressure. When a fire occurs, a fire detecting device, such as a smoke or heat detector, activates and causes the water control valve to open and water to flow into the pipe system The difference, however, is that water is held from piping by an electrically operated valve, known as a pre-action valve. Valve operation is controlled by independent flame, heat, or smoke detection. Deluge Systems Deluge sprinkler systems employ automatic sprinklers which are open at all times. When a fire occurs, a fire detecting device, usually a heat detector, activates and causes the deluge valve to open. Water then will flow into the piping and discharge through all the open sprinklers. Vortex Fire Suppression System The Vortex Fire Suppression System uses both water and nitrogen homogeneously to extinguish fires. This technology uses a small water drop that will absorb more heat while the nitrogen will reduce the oxygen feeding the fire Foam / Chemical Suppression Foam is used whenever there is a possibility of a liquid fire. The Foam will mix with water and then expand over the liquid that is on fire, cool the fire, and finally will be extinguished. The distribution of a foam blanket over a flammable liquid will extinguish a fire by eliminating the fire's oxygen supply and provide a cooling effect on the burning fuel. Foam is also available for the protection of hydrocarbon fuels and polar solvent fuels such as ethanol Gaseous Fire Suppression INERT GASES Gaseous fire suppression is a term to describe the use of inert gases and chemical agents to extinguish a fire. Inert gasses work by removing the oxygen in the hazard to a point where it will not support a fire. Portable Fire Extinguishers PORTABLE FIRE EXTINGUISHERS PORTABLE FIRE EXTINGUISHERS A Fire extinguisher is a device which can be used to control a fire. A fire extinguisher is an external fire safety system useful to extinguish or control minor fires, often in emergency cases A "portable fire extinguisher“ ;-an appliance, apparatus, container or device that is designed to be, or is capable of being, readily moved and that contains or produces any liquid, powder or gas usable for the purpose of extinguishing fire. This definition includes items for recharge or refill. THE PRINCIPLES ON WHICH FIRE EXTINGUISHERS WORK ARE: • Basics principles on which fire extinguishers works: 1. Smothering ;- Reducing the oxygen level in the air to below 16%, which will then die when the surrounding oxygen is used up. 2. Cooling: It involves the process of reducing heat or removal of heat. 3. Starvation: It involves the removal of fuel from the scene of fire 4. Chain breaking 1) the cooling effect of water; 2) the fire-extinguishing effect of carbon dioxide; 3) the blanketing or shutting-off effect of foam; 4) the smothering effect of solid substance; and 5) the combining of more than one effect. TYPES OF FIRE EXTINGUISHERS There are two different types of fire extinguishers: 1. cartridge-operated ; A cartridge-operated extinguisher has just powder/agent inside, and there is a separate pressure cartridge that has to be activated to pressurize the extinguisher 2. stored-pressure. ; A stored pressure extinguisher has the agent and pressure mixed in the same container inside of the extinguisher Fire extinguishers further categorize into 1. Hand-held

- 9. Vijay Kumar GEC 9 2. Trolley mounted 3. Cart-mounted (also called wheeled extinguishers). Fire extinguisher types 1. Portable fire extinguisher 2. Semi-portable fire extinguisher 3. Fixed type fire fighting equipment The different types of hand portable fire extinguishers are 1. Water Extinguisher 2. Soda-acid extinguishers; 3. Foam extinguishers a) Chemical foam extinguishers, and b) Mechanical or air-foam extinguishers; 4. Carbon dioxide snow extinguishers; 5. Dry chemical (dry powder) extinguishers; and 6. ABC , Multipurpose dry chemical (dry powder) extinguisher WATER FIRE EXTINGUISHERS • Water based extinguishers are essentially filled with water and use compressed air to help this come out. • Some will also have an additive that will help make them more effective. • They work to cool the fire, removing heat from the fire triangle and will effectively stop any fire that has started. • Water extinguishers are very common and should be used on solid materials only. This can include paper, wood or any other solid fuel • Used for class A fire( solid fire) • fire extinguisher of 9Ltr are used • Cylinder; made up of solid drawn steel and internally zinc coated • The outer container is filled with water and fitted with a CO2 74mg at 36 bar pressure Cartridge (inner container) which forces the water out of the container with pressure.

- 10. Vijay Kumar GEC 10 • To operate the extinguisher, first, the safety pin/clip is released. • When pressure is applied on the plunger, the CO2 cartridge ruptures and forces the water out of the extinguisher. • Use for: Organic materials such as: Paper and cardboard Fabrics and textiles Wood and coal • Do not use for: Fires involving electrical equipment Kitchen fires Flammable gas and liquids Procedure to use 1. Identify the fire (Class A) 2. Carry the extinguisher near the fire 3. Keep extinguisher towards the fire 4. Remove the safety pin and strike the plunger to pierce CO2 cartridge 5. When it will pierce the pressure created on the upper part of the container and water from the dip tube will pass and be thrown as a jet 6. direct jet towards the fire SODA-ACID FIRE EXTINGUISHERS Sodium bicarbonate (soda) and sulphuric acid are the prime components of the extinguisher. They combine to form a chemical reaction to produce carbon dioxide gas, which is used to smother the fire. The extinguisher consists of a conical or cylindrical sheet steel container charged with basic sodium bicarbonate solution,8 lt water, 400 g NaHCo3 a hermetically-sealed acid phial or bottle (sulphuric acid), a perforated acid bottle metal cage, Asiphon or discharge tube, a nozzle, and a plunger knob assembly. The extinguisher is operated by breaking the acid phial with the plunger knob, permitting the acid and soda solutions to mix and directing the nozzle at the same time towards the fire with the extinguisher held almost horizontally

- 11. Vijay Kumar GEC 11 The chemical reaction produces carbon dioxide in such a quantity that a pressure of about 6.5 bar(g) is developed which forces the whole of the contents of the extinguisher to discharge on to the tire. • carbon dioxide gas which forms a blanket around the burning substance and cuts off the supply of air to the burning substance. This stops the process of burning and fire gets extinguished. fire by cooling action, A soda acid type fire extinguisher is recommended for putting out fires which involve burning of class A fires. FOAM FIRE EXTINGUISHERS This type of extinguisher produces, when operated, a thick foamy fluid either a)Chemical foam extinguishers, ; by reaction between two chemical solutions b) Mechanical or air-foam extinguishers ;by stirring powerfully an aqueous solution of a foam forming compound by means of compressed air (mechanical or air-foam type). How foam extinguishers work: When directed against a fire, the foam spreads over the entire fire covering or blanketing it thus cutting of the oxygen supply.with water extinguishers, foam extinguishers have a cooling effect on the fuel. Chemical foam Fire Extinguishers The chemicals used in this foam type fire extinguisher are sodium bicarbonate and aluminium sulphate. The main container is filled with sodium bicarbonate, whereas the inner container is filled with aluminium sulphate. The extinguisher is operated by inverting it, permitting the acid and basic solutions to mix, and directing the nozzle which may be fitted with a short length of hose on to the fire to be extinguished. The chemical reaction produces gelatinous aluminium hydroxide and carbon di oxide The carbon dioxide is liberated in a state of very fine bubbles which are maintained in that state by the foam- forming compound. The light gelatinous precipitate has the effect of making the bubbles more tenacious and permanent thereby giving very stable- foam. The excess carbon dioxide under pressure serves to force the foam in a stream out of the nozzle. • . Mechanical or air-foam Fire Extinguishers air-foam extinguisher consists of a cylindrical container filled with an aqueous solution of a foam-forming compound or foam concentrate, a siphon tube, a mixing chamber, a discharge hose, a nozzle , a safety valve, and a compressed-air cylinder fitted with a cylinder valve one hand wheel type and accommodated in the centre of the container.

- 12. Vijay Kumar GEC 12 The extinguisher is operated by turning on compressed air by means or hand wheel. The compressed air which is at a pressure of l50 bar(g) is reduced to a pressure of 8 bar(g) by a reducing valve before it exerts Pressure on the top of the solution forcing it up the siphon tube and the mixing chamber A part of the compressed air flowing through a hole in and lube at its top mixes with the solution in the mixing chamber the resulting mixture is converted into a very fine-bubbled air foam in the discharge hose and forced out of the nozzle. Foam extinguishers are especially used for fighting fires involving combustible and flammable liquids. They are not recommended for use in fighting electrical fires . Use for: • Organic materials such as: Paper and cardboard, • Fabrics and textiles • Wood and coal • Flammable liquids, like paint and petrol Do not use for: • Kitchen fires • Fires involving electrical equipment • Flammable metals CARBON DIOXIDE PORTABLE FIRE EXTINGUISHERS A carbon dioxide snow extinguisher consists essentially of a light steel cylinder of about 8-litrecapacity filled with a charge of 6 kg liquid carbon dioxide under a pressure of 56 to 63 bar(absolut). The cylinder valve which may be of hand wheel, lever, Or handgrip type is fitted with a tube that nearly reaches the bottom of the cylinder and is also connected by means of a short length of high-pressure hose (about 1 m long) either directly or through an extension pipe to a snow pipe or discharge horn. When the valve is opened, a portion of the liquid carbon dioxide evaporates at an orifice at the closed end of the horn by expansion to gas.

- 13. Vijay Kumar GEC 13 This chills the horn to low temperatures. When the gaseous carbon dioxide further expands by streaming through the horn to the atmospheric pressure, the remaining carbon dioxide is converted into loose snow due to intense cooling (-79°C) in the horn. Thus, the extinguishing stream consists of an undercooled carbon dioxide gas with finely divided now. A safety device on the cylinder valve prevents undue excess pressure in the steel cylinder. How CO2 extinguishers work: • CO2 extinguishers suffocate fires by displacing the oxygen the fire needs to burn. • Carbon dioxide fire extinguishers extinguish fire by taking away the oxygen element of the fire triangle, and by removing the heat with a very cold discharge. Use for: • Carbon dioxide extinguishers are mainly used for class B(flammable liquid fire) or class C fires( gaseous fire) • They are not used for accommodation areas and confined spaces because of the gas used in lethal. • – Flammable liquids, like paint and petrol – Electrical fires Do not use for: – Kitchen fires – especially chip-pan fires – Combustible materials like paper, wood or textiles – Flammable metals DRY POWDER FIRE EXTINGUISHERS This type of extinguisher uses a fire-quenching chemical powder with bicarbonate base for its action The dry chemical commercially available is made up of one or more of five basic powders: sodium bicarbonate, potassium bicarbonate, urea potassium bicarbonate, potassium chloride and monoammonium phosphate with various additives to improve their storage and flow characteristic. Sodium bicarbonate powder is used to extinguish almost all types of fires. Chief among the additives are metallic stearates and tri calcium phosphate. Potassium bicarbonate-base dry chemical has a faster extinguishing action than the sodium bicarbonate base type Dry powder extinguisher contains sodium bicarbonate powder in the outer container. A small container with carbon dioxide is placed beneath the plunger mechanism. When the plunger is pushed, it releases the carbon dioxide gas, which in turn forces the dry powder out of the discharge nozzle. • How extinguishers work • When used on a fire, the dry chemical causes the flame to go out at once. • The exact mechanism and chemistry of the extinguishing action are not definitely known.

- 14. Vijay Kumar GEC 14 • Dry powder extinguishers smother fires by forming a barrier between the fuel and the source of oxygen. • Smothering, cooling,radiation Shielding and chain-breaking reactions in the combustion zone are con my responsible for the extinguishing action of the dry chemical. Use for: 1. Organic materials such as: Paper and cardboard, Fabrics and textiles, Wood and coal 2. Flammable liquids, like paint and petrol 3. Flammable gases, like liquid petroleum gas (LPG) and acetylene 4. Fires involving electrical equipment up to 1000v 5. Specialist dry powder extinguishers are only used on flammable metals, such as titanium and magnesium. Do not use for: 1. Fires involving cooking oil 2. Fires involving electrical equipment over 1000v 3. in enclosed spaces, such as offices or residential properties ABC, MULTI PURPOSE DRY CHEMICAL (DRY POWDER) EXTINGUISHERS "ABC" fire extinguishers are filled with a fine, yellow powder.. ABC or Multi-Purpose extinguishers comprise of a special fluidized and siliconized mono ammonium phosphate dry chemical and additive which improve storage and flow characteristics. The greatest portion of this powder is composed of monoammonium phosphate The extinguishers are pressurized with nitrogen. It has little cooling effect on the ire but its extinguishing action is considered as due to the inhibiting effect of the liberated ammonia and the formation of an adhering glassy crust of metaphosphoric acid over the fire in ordinary combustible materials, which tends to retard further combustion. The mechanism causing a flammable liquid fire to go out is believed to be a chain-breaking reaction • The extinguishers may be either of the stored-pressure type (the charge under constant pressure of the expellant gas) or of the cylinder or cartridge. operated type. • The working pressure of the stored-pressure extinguishers at ordinary temperature using carbon dioxide expellant is 21 bar(g). • The extinguishers are effective against glow fires, flaming fires, flammable liquid fires, and electrical fires • The most widely used type of fire extinguisher is the multipurpose dry chemical that is effective on Class A, B, and C fires. • An extinguisher with an ABC rating is suitable for use with fires involving ordinary combustibles, flammable liquids and energized electrical equipment

- 15. Vijay Kumar GEC 15 • These fire extinguishers are economical and extremely versatile. • They are ideal for tackling the majority of fire risks typically found in commercial, industrial and domestic applications. FIRE DETECTING DEVICES A key aspect of fire protection is to identify a developing fire emergency in a timely manner, and to alert the building's occupants and fire emergency organizations.This is the role of fire detection and alarm systems. Depending on the anticipated fire scenario, building and use type, number and type of occupants and criticality of contents and mission, these systems can provide several main functions: First, they provide a means to identify a developing fire through either manual or automatic methods. Second, they alert building occupants to a fire condition and the need to evacuate. Another common function is the transmission of an alarm notification signal to the fire department or other emergency response organization. They may also shut down electrical, air handling equipment or special process operations, and they may be used to initiate automatic suppression systems.

- 16. Vijay Kumar GEC 16 Thermal Detectors ▪ Thermal detectors are temperature Thermal detectors are temperature-activated sensors to initiate an alarm activated sensors to initiate an alarm. 1) Fixed-temperature type: This sensor consists of normally open contact held by bimetallic elements that will close the contacts when the ambient temperature reaches a fixed setting. The setting is generally designed for operation at setting is generally designed for operation at 57℃, 88 ℃, or 94℃. 2) 2. Rate-of-rise (ROR) type: This sensor reacts to the rate at which the temperature rises. It contains a sealed but slightly vented air chamber which expands quickly when the temperature near the device rises quickly When the air chamber expands faster than it can be vented near the device rises quickly. When the air chamber expands faster than it can be vented, electrical contacts attached to the chamber begin to close and thus initiate an alarm. 3) Combination type: This device reacts to both a fixed temperature and a rate of rise. 10.5.3 Smoke Detectors Smoke detectors are quicker to respond than thermal detectors Smoke detectors are quicker to respond than thermal detectors. i. Photoelectric type ii. Ionization type iii. Light Scattering iv. Light Obscuring 1) Photoelectric type This type operates on the principle of the scattering of light This type operates on the principle of the scattering of light. Photoelectric detectors Photoelectric detectors detect the presence of visible particles (larger than 3 microns) in the air. Inside the detector, there is a light emitting diode (LED) that directs a narrow beam of infrared light across the detection chamber. light across the detection chamber. When smoke or particles enter the chamber, the When smoke or particles enter the chamber, the infrared light beam is scattered. A photodiode or photo detector, usually placed 90 degrees to the beam, will sense the scattered infrared light and when a preset amount of lig , ht is detected, the alarm will sound. Photoelectric detectors are not as sensitive and are designed to detect cool or slow-moving (smoldering) fires that produce a lot of smoke. 2) Ionization type This type operates on the principle of changing conductivity of air within the detector This type operates on the principle of changing conductivity of air within the detector chamber. The ionization detector uses a small amount of radioactive material to make the air within a sensing chamber conduct electricity. When smoke particles or combustion gases enter the sensing chamber they interfere with the conduction of combustion gases enter the sensing chamber they interfere with the conduction of electricity, reducing the current and triggering an alarm. The ionization detector can detect even invisible combustion gases produced by an open flame and will therefore resp g ond slightly p p faster to an open flame fire than a photo-electric detector. here are three basic types of smoke detectors including: 3. Light Scattering Smoke Detector The light scattering smoke detector operates on the Tyndall effect; a photocell and light source are separated from each other by a darkened chamber such that the light source does not fall on the photocell. The passage of smoke into the chamber causes the light from the source to be scattered and fall on the photocell. The photocell output is being used to initiate an alarm. 4. Light Obscuring Smoke Detector In the Light obscuring smoke detector, smoke interferes with a light beam between a light source and photocell. The photocell measures the amount of light it receives. The variation in photocell output, is being used to initiate an alarm. This type of fire detection equipment can be used to protect large areas with the light source and photocell positioned some distance apart.

- 17. Vijay Kumar GEC 17 Flame Detectors ▪ Flame detectors are used to detect the direct radiation of a flame in the visible, infrared, and ultraviolet ranges of the spectrum. Flame detectors are used mostly in industrial processes for the protection of combustion equipment. Thermal or smoke detectors would be unreliable and generate false alarms in these environment. ▪ There are four basic types: 1. Infrared detector 2. Ultraviolet detector 3. Photoelectric detector 4. flame flicker detector Carbon Monoxide Detectors Carbon monoxide detector is also known as CO detector. It is an electronic device which contains on different types of sensors used to measure and sense the amount of carbon monoxide gas in the air. When the level of carbon monoxide (it is a poisonous gas produced by combustion) crosses the specified limit, it indicates and triggers the fire alarm system. The electrochemical cell inside the carbon monoxide detector only sense and measure the amount of CO gas and not other combustion gases like smoke etc. Keep in mind that the carbon monoxide detectors designed for fire alarm system are more sensitive with quick response as compared to the CO detectors used in homes for CO protection in case of incomplete combustion process in appliances such as boilers etc. Multi-Sensor Detectors The multi sensor detector (also known as multi-criteria alarm) is a sensitive device which combines the input signal from both heat and optical sensors and used for wide range of fires with lower rate of unwanted false alarms. It can be used to detect optical, heat, CO and fires as it has the ability to detects multiple signals and send the identification value to the control panel for further appropriate action. Hence, an intelligent multi-sensors alarm can be used for accurate and verified correct operation. Manual Call Points A Manual Call Point or Break Glass Call Point is a device which enables personnel to raise the alarm by breaking the frangible element on the fascia; this then triggers the alarm. FIREFIGHTING INSTALLATION Fire fighting installation is a complete fire hydrant, fire sprinkler, above-ground pump room and overhead tank pump room work which involve complete piping welding and installation of various accessories such as hydrant valve, hose pipe, branch pipe, hose reel drum, hose box, main electrical pump, generator pump, stand by pump, jockey pump and booster pump. It also involves commissioning fire alarm system, firefighter’s telephone and talkback system fire installation CONTENT: 1. Wet Riser and Dry Riser 2. Sprinklers System 3. Co2 Fire suppression 4. Clean Agent Gas 5. Hose reel 6. Smoke detection 7. Heat detection 8. Hydrant System 9. Fire panel troubleshooting 10. Downcomer 11. Fire Pumps 12. Manual Detection/Manual Call Point

- 18. Vijay Kumar GEC 18 13. Fire Intercom Fixed fire installation? A fixed firefighting system is a fire suppression, control or extinguishing system for use as a fixed installation in a building to protect the whole or part of a building and/or the objects within They are of 1. fixed flow type, 2. adjustable flow (variable discharge) type and 3. a combination type. They include: Hose Reels Permanent hose reels are installed in accordance with BS EN 671-3: 2000 and provide an effective fire- fighting facility. They may offer an alternative, or be in addition to, portable fire-fighting equipment. Sprinkler Systems Sprinkler systems designed to protect life and/or property and may be regarded as a cost-effective solution for reducing the risks created by fire as they can be very effective in controlling fires. A sprinkler system is usually part of a package of fire precautions in a building and may form an integral part of the fire strategy for the building. Sprinkler protection could give additional benefits, such as a reduction in the amount of portable fire- fighting equipment necessary, and the relaxation of restrictions in the design of buildings. Guidance on the design and installation of new sprinkler systems and the maintenance are provided by BS EN 12845 or BS 5306-2. Guidance is available from the Fire Safety Advice Centre on domestic and industrial fire sprinkler system, which can be accessed from the links below. Wet and Dry Risers Wet and Dry risers are intended for the use of the Fire Service to provide a readily available means of delivering considerable quantities of water. Dry risers are vertical mains fitted into staircase enclosures or other suitable positions, constructed of 4'' galvanized steel pipe with outlet valves on each floor and an inlet fitted at ground level to enable the fire brigade to connect to the water supply. Wet risers are pipes kept permanently charged with water either from a storage tank (via a booster pump) or direct from the town's main water supply. Foam Inlets Foam inlets are special inlets usually fitted to provide an efficient way of extinguishing a fire in a basement or other area of high risk such as plant room. In many respects they look the same as rising main inlet boxes, but the door should be clearly marked "foam inlet". The risk area should be kept clear of obstructions to allow the foam to spread into the compartment. Sprinkler Systems This is a system containing pipe-work which can be filled with water (wet system) with a sprinkler which seals the pipe-work. If the temperature reaches a certain level the glass breaks and release water in the area of the fire. An alternative system is where the pipe-work is not filled with water until the sprinkler bulb is broken which then lets water into the system. Further details can be found on the Residential Sprinkler Associate website below. FUNDAMENTALS OF INDUSTRIAL SAFETY Industrial safety is primarily a management activity which is concerned with Reducing Controlling Eliminating hazards from the industries or industrial units. “Measures or techniques implemented to reduce the risk of injury, loss and danger to persons, property or the environment, in any facility or place involving the manufacturing, producing and processing of goods or merchandise.”

- 19. Vijay Kumar GEC 19 WHY IS INDUSTRIAL SAFETY NECESSARY? A tendency is not always like a static approach and this question why is industrial safety necessary is a most important one the necessity is of safety and security and above all if there is a solution to prevent safety measures than why not get it onboard. Organisations are aware that the mis happenings should be avoided as the safety options are available for the employee and workstation safety zone. Industrial Safety ensures that there are strict protocols. It increases the Employee awareness for having all safety measures. Planning of Industrial Safety will help to avoid hazardous situations. Human Loss and Industrial material loss can be Controlled. SIGNIFICANCE OF INDUSTRIAL SAFETY 1. Industrial causes a great loss to both the Employer & Employee, that’s it is having importance 2. Cost of compensation 3. Cost of medical-aid 4. Cost of training a new worker 5. Cost of the lost time 6. Cost of investigation 7. Cost of supervision & inspections 8. Cost to the Govt. in terms of factory inspectors, & public health services Contd. 9. Cost of spoilage of materials 10. Cost of the damage of machinery 11. Cost of cost of wages payble during injury 12. Cost of loss of morale; & 13. Cost of loss to the worker and his family OBJECTIVE OF INDUSTRIAL SAFETY 1. To prevent accidents in the plant by reducing the hazard to minimum. 2. To eliminate accident caused work stoppage and lost production. 3. To achieve lower workmen’s compensation, insurance rates and reduce all other direct and indirect costs of accidents. 4. To prevent loss of life, permanent disability and the loss of income of worker by eliminating causes of accidents. 5. To evaluate employee’s morale by promoting safe work place and good working condition 6. To educate all members of the organization in continuous state of safety mindless and to make supervision competent and intensely safety minded.

- 20. Vijay Kumar GEC 20 TYPES OF HAZARDS IN INDUSTRY Types of Hazards Hazard is defined as something which has the potential to cause harm. Danger is synonymous with hazard. Anything of such nature which has possibility to cause harm in some way, even theoretically, is considered a hazard. Hazard can occur due to different reasons and the occurrence may have different consequences thus the hazards have been categorized to fall in different classes. The importance of segregation of hazards is to be able to identify what measures are to be taken to reduce or eliminate a risk. Hazard is classified in six types in chemical industry; chemical hazard, biological hazard, physical hazard, safety hazard, ergonomic hazard, psychological hazard. Chemical Hazard: Working with chemicals is central to a job in a chemical industry. Different chemicals affect personals and environment in different ways. Some are toxic, some are flammable, some are quite corrosive, some are carcinogenic. Contact of such chemicals can do variety of harm to human body. If an accident is to occur then some chemicals are also liable to cause harm at a mass scale. If it is necessary to use a hazardous chemical then it is extremely important to train the personal properly with SOP prior to placing the person in that part of the process where that chemical is used. Biological Hazard: All the potential of harm which can be caused by viruses, bacterias, or fungi falls under this category. Such agents are liable to cause infections, allergies, and poisoning. Those personals infected by such agents can also spread it to others in same cases if the agents are contagious in nature. Such agents often find a ground to multiply wheresoever there is stagnation of water even if the volume of stagnant water is very less, for example this is a problem which occurs especially in and near cooling towers, the aerobic bacteria which commonly is found in and near cooling tower is Legionella. Physical Hazard: Variety of environmental factors fall in this category. Basically they refer to those things present in the environment which can cause harm to the human body. It is not necessary that they are physical or tangible things. Heat or any electromagnetic radiation, and noise also fall under this category. If a chemical is spilled on floor then it also has potential to harm the physical body so it also comes under physical hazard. Safety Hazard: This category refers to all those materials or a situation which comprises the safety condition in the plant. Improper placement of gas cylinders, improper handling of flammable materials, poor lighting, insufficient use of safety equipments are some of the examples which dictate a potential for safety hazard. Ergonomic Hazard: This is a special type of category which refers to those potentials which can cause musculoskeletal injuries to a person. Essentially those factors which can cause posture to deteriorate and put strain on body comes under this classification. This type of hazard is very hard to observe, usually it is seen only after certain degree of damage has been done to the human body. Some examples are; no place to walk, repetitive manual handling, less place to work, etc. Psychological Hazards: Those situation or behavior which causes mental harm to personals and interferes with their mental well- being falls under this category. All situations which cause stress, anxiety, depression, and sexual harassment fall under this category. Electrical hazards Electrical Falls caused as a result of contact with electrical energy. 11 Burns and Electric shock, Electrocution (fatal), injuries consist of four main types: receive a shock when he/she: i. Touches two wires at different voltages at the same time. ii. Touches phase and neutral wire at a time iii. Touches the phase standing on the ground iv. Touches the phase having wet cloth, high humidity and perspiration.

- 21. Vijay Kumar GEC 21 Fire and Dust hazard ;- Electrostatic separator , Inertial separator Filtration During capsule filling and tablet punching operation dusts may be generated. Methods of controlling dust During coating operation dusts are generated. During powder mixing dusts may be generated. During weighing dusts may float on air. Grinding or milling of drugs, excipients, or herbal products. DUST HAZARDS Source of dust hazards in pharmaceutical industries Types of fire Class D Fires: These are fires in combustible metals. Class C Fires: These fires involve energized electrical equipment. Class B Fires: These are fires of flammable petroleum products, liquids, gases and greases etc. Class A Fires: These are fires in ordinary combustible materials such as wood, cloth, paper etc. those produce glowing ember. hazards: CAUSES OF INDUSTRIAL ACCIDENTS 1. Unsafe conditions a. The job itself b. Work schedules c. Psychological conditions d. Machinery & Equipment , Environment- Poor lighting ,Ambient temperature , Air pollution ,Sound pollution – 2. Unsafe Acts 3. Miscellaneous Causes Unsafe Conditions (Work-Related Causes): These, of one sort or another, are the biggest cause of accidents. Such causes are associated with defective plants, equipment, tools, materials, buildings etc. These can be termed ‘technical causes. They arise when there are improper or inadequate safety guards on machines; when machines break down; when improper personal protection equipment is installed; when mechanical or construction designs are defective and unsafe; and when control devices, which have been installed to make the operation of machines safe and accident free are lacking or defective; or when there is an absence of proper maintenance and supervision of these devices. Thus, unsafe conditions include: i. Improperly guarded equipment. ii. Defective equipment. iii. Hazardous arrangement or procedure in and or around, machines or equipment. iv. Unsafe storage; congestion, overloading. v. Inadequate safety devices. vi. Wrong and faulty lay-out, and bad location. vii. Improper illumination — glare, insufficient light. viii. Improper ventilation — insufficient air charge, impure air source. ix. Poor house-keeping. The other work related causes of accidents are: (a) The job itself- Some jobs are inherently more dangerous than others, such as the job of crane-man in comparison to that of the foreman. Similarly, work in some departments (like personnel) is inherently safer than the work in others (like production department).

- 22. Vijay Kumar GEC 22 (b) Work schedules, accidents increase late in the day. They do not usually occur during the early hours of the work day. They are more frequent during the night shift. This is due partly to fatigue and partly to the fact that night is the period when one requires rest. (c) Psychological climate of the work place also affects the accident rate. Psychological, mental and emotional imbalances are at the root of several accidents. 2. Unsafe Acts: These acts may be the result of lack of knowledge or skill on the part of the employee, certain physical defects and wrong attitudes. These acts include acts like: i. Operating without authority. ii. Failing to secure equipment or warning other employees of possible danger. iii. Failing to use safe attire or personal protective equipment. iv. Throwing materials on the floor carelessly. v. Operating or working at unsafe levels of speed, either too fast or too slow. vi. Making safety devices inoperative by removing, adjusting, disconnecting them. vii. Using unsafe equipment or using equipment unsafely. viii. Using unsafe procedures in loading, placing, mixing, combining. ix. Taking unsafe positions, under suspended loads. x. Lifting improperly. xi. Cleaning, adjusting, oiling, repairing, etc. or moving a dangerous equipment. xii. Distracting, teasing, abusing, startling, quarreling, day-dreaming, horseplay. Personal Characteristics also influence accident behaviours of individuals. For example, characteristics like personality and motivation serve as a basis for certain behaviour tendencies — such as tendencies to take risks and undesirable attitudes. 3. Other Causes: These causes arise out of unsafe situational and climate conditions and variations — such as bad working conditions, rough and slippery floors, excessive glare, heat, humidity, dust and fume-laden atmosphere; very long hours of work; unsatisfactory behaviour of domineering supervisors; excessive noise and carelessness in the handling of such inflammable materials such as gasoline, solvents, oil and grease, explosives etc. Unsafe condition 1. Improperly guarded equipment 2. Inadequate warring system 3. Poor Ventilation system 4. Fire and Explosive hazard 5. Improper plant layout 6. Congestion of workplace 7. Hazardous atmospheric conditions 8. Poor Housekeeping 9. Excessive nose and Radiation exposure Unsafe act 1. Operating equipment at improper speed 2. Operating equipment without authority 3. Using equipment improperly 4. Engaging with gambling 5. Use of alcohols by employees 6. Improper loading and placement of equipment 7. Improper ailing and taking improper position 8. Using Defective equipment

- 23. Vijay Kumar GEC 23 MEASURES TO ENSURE INDUSTRIAL SAFETY Fours of safety 1. Engineering: i.e. safety at the design, equipment installation stage. 2. Education: i.e. education of employees in safe practices. 3. Enlistment: i.e. it concerns the attitude of the employees and management towards the programmed and its purpose. This necessary arose the interest of employees in accident prevention and safety consciousness. 4. Encouragement: i.e. to enforce adherence to safe rules and practices 1. Safety Policy 2. Safety Committee 3. Safety Engineering a. Guarding of machinery b. Material handling equipment c. Safety devices d. Ergonomics e. Plan maintenance f. General house keeping 4. Safety Education & Training 5. Role of Government Steps to Prevent Industrial Accidents Some of the steps for preventing industrial accidents are as follows 1. Proper safety measures 2. Proper selection

- 24. Vijay Kumar GEC 24 3. Safety conscious 4. Enforcement of discipline 5. Incentives 6. Safety committees 7. Proper maintenance of machines, equipment and infrastructural facilities 8. Safety training. 1. Proper safety measures: The proper safety measures should be adopted to avoid accidents Government also provides guidelines for enacting measures for checking accidents, these should be properly followed. 2. Proper selection: Any wrong selection of workers will create problems later on. Some time employees are accident prone, they may not be properly suitable for the particular jobs. So the selection of employees should be on the basis of properly devised tests so that their suitability for jobs is determined. 3. Safety conscious: The employees should be made conscious of various safety measures to be followed. There should be proper working slogans and advises to the worker for making them conscious. 4. Enforcement of discipline: Disciplinary action should be taken against those who flout safety measures. There may be negative punishments like warnings, lay off, terminations of workers. 5. Incentives: Workers should be given various incentives for maintaining safety. There may also be safety contrasts among workers. Those who follow safety instructions properly should be given monetary and nonmonetary incentives. 6. Safety committees: Safety measures are in the interest of both employers. There should be committees consisting of representatives of workers and employees for devising and enforcing safety programmes. 7. Proper maintenance of machines, equipment and infrastructural facilities: Accidents may occur on account of the fault in machines or equipment. There should be proper maintenance of machines. These should be regularly checked and frequently inspected by engineering 8. Safety training: The workers should be given training regarding safety measures. They should know the hazards of the machines, the areas of accident proneness and the good working possible precautions in case of some accident SAFETY SYSTEMS An industrial safety system is a countermeasure crucial in any hazardous plants such as oil and gas plants and nuclear plants. They are used to protect human, industrial plant, and the environment in case of the process going beyond the allowed control margins. safety system means the integrated total system, including the pertinent elements of the press, the controls, the safeguarding and any required supplemental safeguarding, and their interfaces with the operator, and the environment, designed, constructed and arranged to operate together as a unit, such that a single failure or single operating error will not cause injury to personnel due to point of operation hazards. As the name suggests, these systems are not intended for controlling the process itself but rather protection The function of a safety system is to monitor and control conditions on a machine or process that are hazardous Potential risks for machine operators Potential damage to machines/goods Potential damage to environment Systems and components must be designed such that they are safe under normal conditions. Faults, failures and external influences must not result in an undetected loss of safety

- 25. Vijay Kumar GEC 25 Types of industrial safety systems There are three main types of industrial safety systems in process industry: 1. Process Safety System or Process Shutdown System, (PSS). 2. Safety Shutdown System (SSS): This includes Emergency Shutdown-(ESD) and Emergency Depressurization-(EDP) Systems. 3. Fire and Gas System (FGS).These systems may also be redefined in terms of ESD/EDP levels SSS The safety shutdown system shall shutdown the facilities to a safe state in case of an emergency situation, thus protecting personnel, the environment and the asset. Safety Shutdown System shall manage all inputs and outputs relative to Emergency Shut Down (ESD) functions (environment & personnel protection). This system might also be fed by signals from the main fire and gas system FGS The main objectives of the fire and gas system are to protect personnel, environment, and plant (including equipment and structures). The FGS shall achieve these objectives by: Detecting at an early stage, the presence of flammable gas, Detecting at an early stage, the liquid spill (LPG and LNG),Detecting incipient fire and the presence of fire, Providing automatic and/or facilities for manual activation of the fire protection system as required, Initiating signals, both audible and visible as required, to warn of the detected hazards, Initiating automatic shutdown of equipment and ventilation if 2 out of 2 or 2 out of 3 detectors Initiating the exhausting system. ESD Emergency Shutdown-(ESD) systems are aimed at isolating (closing) any hazardous valves in a process due to abnormal conditions. EDP Due to closing ESD valves in a process, there may be some trapped flammable fluids, and these must be released in order to avoid any undesired consequences (such as pressure increase in vessels and piping). For this, emergency depressurization (EDP) systems are used in conjunction with the ESD systems to release (to a safe location and in a safe manner) such trapped fluids. PSV Pressure safety valves or PSVs are mechanical devices and are usually used as a final safety solution when all previous systems fail to prevent any further pressure accumulation and protect vessels from rupture due to overpressure SAFETY EQUIPMENTS Safety Equipment, as implied by its name, includes the gadgets that are used (worn, used, suspended etc.) for the protection of life and to avoid injuries or casualties.

- 26. Vijay Kumar GEC 26 Generally, safety equipment definition is the protection that is used by workers to avoid injuries, casualties, life threatening situations etc. Different types of safety equipment are used by workers depending upon the nature of risk involved in the work. list of industrial safety equipment 1. Protective Glasses 2. Face Shield 3. Fire Extinguishers 4. Hearing Protection 5. Safety Shoes 6. Safety Helmets 7. Protective Gloves 8. Industrial Cleaning Tools 9. Face Masks & Respirators 10. Industrial Safety Equipment for Fall Protection

- 27. Vijay Kumar GEC 27 1. Safety glasses The important industrial safety equipment worn by workers, safety glasses protect from severe damage caused to the eyes while performing welding or soldering tasks or from the dust and debris produced by certain power tools. They are worn while operating lathe machines to avoid projectiles from entering the eyes. 2. Hearing protection Several industrial activities produce higher levels of noise. Daily or frequent exposure to such types of increased noises can cause hearing impairment or hearing loss. Using earplugs can be of great help in safeguarding against these extreme noises. 3. Safety gloves They protect the workers’ hands from chemicals, sharp objects, sensitive materials and extreme temperatures. Look for gloves with proper fitting, which must be compatible with the material and suitable for the concerned tasks. 4. Face shield- Industrial Safety Equipment

- 28. Vijay Kumar GEC 28 A face shield protects the workers’ faces when using lathes and similar machinery or equipment as it produces plenty of flying chips. They are comfortable and easy to use and can be flipped upwards when not in use. 5. Safety helmets These safeguard the most fragile and highly important part of the human body- the brain. Safety helmets provide protection against fatal incidents that commonly take place in industrial work areas. 6. Safety shoes The resilient shoes protect the workers feet from potential injuries that occur from any heavy machines and equipment hitting the feet, sharp objects that lacerate the feet and burns to name a few. Safety shoes are more comfortable, provide a firm grip and relieve pain from standing for several hours at work in factories, etc. Gas and Fire Detectors: We tend to forget some industrial safety equipment like installing gas and fire detectors at the workplace. Now and again, the best working environment risks aren’t quickly perceptible. Burnable gas and carbon monoxide detectors, photoelectric sensors, and air-inspecting frameworks are basic for sticking to security hardware industry guidelines. Emergency Shower Stations: Despite installing the best detectors and making your employees safe with safety equipment, there are still risks. Risks of fire explosion or bursting out of explosive materials and burnable chemicals? Do you have any plan in place for such situations? If not, an emergency shower station is the one you should install. Make sure your workspace does not get affected mostly with these protective measures. 7. Signs and Audio Sensors: The language barrier is often a big gap in communication inside an organization. What to do in alarming situations to get everyone alert? Signs and audio sensors are what you should consider installing. Make a list of audio and signs sensors that are hard to ignore. TYPES OF PPE Skin and Body Protection PPE includes the following categories to protect employees from physical hazards: Body Protection PPE includes safety vests and suits that can be used for tasks that can cause body injuries from extreme temperatures, flames and sparks, toxic chemicals, insect bites and radiation. Hands Protection PPE includes safety gloves and should be used for tasks that can cause hand and skin burns, absorption of harmful substances, cuts, fractures or amputations. Foot Protection PPE includes knee pads and safety boots and should be used for tasks that can cause serious foot and leg injuries from falling or rolling objects, hot substances, electrical hazards, and slippery surfaces. Head Protection PPE includes hard hats and headgears and should be required for tasks that can cause any force or object falling to the head Respiratory protection ; Needed when work presents an inhalation hazard. Respiratory Protective Equipment (RPE) is a particular type of Personal Protective Equipment (PPE), used to protect the individual wearer against the inhalation of hazardous substances in the workplace air.

- 29. Vijay Kumar GEC 29 FACTORY ACT 1948 Salient features of Factories Act, 1948 The important features of the 1948 Act are as follows: The word “factory” has been expanded by the Factories (Amendment) Act of 1976 to include contract labour when determining whether a factory has a maximum of 10 or 20 employees. The Act increased the minimum age for children to work in workplaces from 12 to 14 and reduced their daily working hours from 5 to 4 and a half. The Act forbids women and children from working in factories from 7 p.m. to 6 a.m. The difference between a seasonal and non-seasonal factory has been abolished by the Act. The Act, which has provisions for factory registration and licencing. The state government is required to make sure that all factories are registered and also have valid licences that are renewed from time to time. The Act gives state governments the authority to enact rules and regulations that ask for management and employee association for the benefit of employees. The state government has the authority to apply the Act’s requirements to any establishment, regardless of the number of employees inside and regardless of whether the establishment engages in manufacturing operations. In Rabindra Agarwal v. State of Jharkhand (2010), the Jharkhand High Court held that the Factories Act, special legislation would prevail over the Indian Penal Code Objectives of Factories Act, 1948 The important objectives of the 1948 Act are as follows: The major goal of the Factories Act of 1948 is to establish adequate safety measures and to enhance the health and welfare of workers employed in a factory. The Act also protects workers from various industrial and occupational hazards. o Heath: According to the Act, all factories must be kept clean, and all essential safeguards must be taken to safeguard the health of workers. The factory must have a sufficient drainage system, adequate lighting, ventilation, temperature, etc. There must be clean water supplies.

- 30. Vijay Kumar GEC 30 Separate restrooms and urinals must be built in convenient locations for males and females. These must be freely accessible to employees and kept clean. o Safety: The Act requires that machines be properly fenced; that no young adults work on any dangerous machines in enclosed places, and also that appropriate manholes be provided so that employees may escape in an emergency. o Welfare: The Act specifies that appropriate and suitable washing facilities for workers must be provided and maintained in every factory. There must be storage and drying facilities, as well as sitting areas, first-aid equipment, shelters, restrooms and lunch rooms. The Act also imposes some restrictions on the employment of women, small children, and teenagers, such as working hours, intervals, holidays, etc., as well as on annual leave with pay, etc. o Working hours: The Act sets working hours for all workers, and no adult worker must be permitted to work in a workplace for more than 48 hours per week. Weekly holidays need to be granted. The Act also imposes specific restrictions on owners, occupiers, or the manufacturer’s head in order to safeguard employees and ensure their health and safety precautions. The Act protects workers from exploitation and improves working conditions and the environment within factory premises. o Penalties: The Act also specifies specific rules created with provisions under the Act, and written orders that are violated. It is an offence, and penalties will be imposed, imprisonment for up to a year; a fine of up to one lakh rupees; or both fine and imprisonment. Any employee who misuses equipment related to the welfare, safety, and health of other employees, or those connected to the performance of his duties, suffers a Rs.500 fine. Application of the Factories Act,1948 The important applications of the 1948 Act are as follows: The Act also applies to the whole country of India, including Jammu and Kashmir, and covers all manufacturing processes and premises that fall under the definition of a factory as defined in Section 2(m) of the Act. It also applies to factories owned by the central or state governments, as defined in Section 116 of the Act. The Act is applied and limited to factories that use power and employ 10 or more people on any working day in the preceding 12 months. The Act is applied and limited to factories that do not use power and employ 20 or more people on any working day in the preceding 12 months. The Act is also covered under Section 85 of the Factories Act by the state governments or Union Territories. Important provisions in the Factories Act, 1948 Getting approval, licencing and registration of factories (Section 6) The state government shall make rules that require formal submission of plans of any category or description of factories, as well as the site on which the factory is located, for construction or extension must be submitted to the chief inspector or the state government. This Section requires the registration and licencing of factories, as well as the payment of fees for such registration and licencing, as well as the renewal of licences. No licence is issued or renewed unless the occupier gives notice to the chief inspector. If the state government refuses to grant permission to the site or construction of a factory, then within 30 days of the refusal, the applicant can appeal to the central government. Labour and welfare The word ‘labour welfare’ refers to the services offered to employees within as well as outside the factory, such as canteens, restrooms, recreation areas, housing, and any other amenities that support employee well-

- 31. Vijay Kumar GEC 31 being. States that take welfare measures care about the overall well-being and productivity of their workforce. Early on in the industrialization process, social programmes for manufacturing workers did not receive enough priority. In the past, industrial labour conditions in India were terrible. Due to a growth in industrial activity in the latter part of the twenty-first century, several attempts were made to improve the working conditions of the workforce through the recommendations of the Royal Commission. After gaining knowledge about the deficiencies and limitations of the previous Act, the Factories Act of 1948 was amended. The definition of ‘factory’ was expanded to encompass any industrial facility employing 10 or more people that uses power or any industrial establishment employing more than 20 people that uses no power, which was a significant development. Other significant amendments included- Raising the minimum age of children who can work from 12 to 14 years old. Reducing the number of hours a child can work from five to four and a half. Preventing the kids from working between the hours of 7 p.m. and 6 a.m. The health, safety, and well-being of all types of employees are given particular attention. Welfare measures The three main components of welfare measures are occupational health care, appropriate working hours, and appropriate remuneration. It speaks of a person’s complete health, including their physical, mental, moral, and emotional states. The goal of welfare measures is to integrate the socio-psychological demands of the workforce, the particular technological requirements, the organisational structure and procedures, and the current socio-cultural environment. It fosters a culture of work dedication in enterprises and society at large, ensuring increased employee happiness and productivity. Washing facilities (Section 42) All factories should supply and maintain enough appropriate washing facilities for the use of the employees. For male and female employees, separate, well-screened facilities must be provided; these facilities also need to be easily accessible and maintained clean. The standards for appropriate and suitable facilities for washing must be set by the state government. Facilities for storing and drying clothing (Section 43) The state government has a specific authority. It specifies that the state government has the authority to give instructions to the manufacturers regarding where to store the worker’s clothing. They can also provide them with instructions on how to dry the workers’ clothes. It refers to the circumstance in which workers are not dressed for work. Facilities for sitting (Section 44) All factories should provide and maintain seating arrangements in appropriate areas for all workers who are required to work in a standing position in order to take advantage of any chances for rest that may arise throughout the course of the job. According to the chief inspector, workers in any factory involved in a certain manufacturing process or working in a specific room are able to perform their work effectively while seated. First aid appliance (Section 45) All factories must have first aid kits, appliances, or cupboards stocked with the required supplies during all working hours, and they must be easily accessible for all manufacturing employees to access. Accordingly, there must be more first aid boxes or cupboards than the usual ratio of one for every 150 industrial employees, which must be fewer than that. The first aid box or cupboard should only include the recommended supplies. Throughout the factory’s operating hours, each first aid box or cupboard should be kept under the supervision of a specific person who is accountable for it on a separate basis and must be readily available at all times during the working hours of the factory. Canteen (Section 46)

- 32. Vijay Kumar GEC 32 A canteen must be provided and kept up by the occupier for the benefit of the workers in any specified factory where more than 250 people are usually employed, according to rules that the state government may set. Food must be served, and prices must be established for it. Shelters, restrooms and lunch rooms (Section 47) Every factory with more than 150 employees must have appropriate and suitable restrooms or shelters and a lunchroom with drinking water where employees can eat food they have brought with them and that is kept for their use. If a lunchroom is available, employees should stop eating in the work area. The shelters or restrooms need to be well-lighted, ventilated, kept clean, cool, and in good condition. The state government sets the standards. Creches (Section 48) Every factory with more than 30 female employees must have a suitable room for the use of children under the age of six of such women. Such rooms must be well furnished, well-lighted, and ventilated, and they must be kept clean and hygienic. They must also be under the care of women who have received training in child and infant care. In addition, facilities for washing and changing clothes can be made available for the care of the children of female workers. Any factory may be forced to provide free milk, refreshments, or both to such children. Small children can be fed by their mothers in any industry at necessary intervals. Health Sections 11-20 of Chapter III of the Act deal with the Health of the Factories Act, 1948. Cleanliness (Section 11) Every factory needs to be kept clean and clear of any effluvia from drains, latrines, or other annoyances. In particular: Dirt must be cleaned daily from floors, benches, staircases, and passages by sweeping or by another method, and it must be properly disposed of. The floor should be disinfectant-washed at least once a week. During the manufacturing process, the floor becomes moist; this must be drained via drainage. Disposal of wastes and effluents (Section 12) Every factory has to have a method in place for treating wastes and effluents produced by the manufacturing process they use. Ventilation and temperature (Section 13) In order to ensure worker comfort and prevent health problems, sufficient ventilation must be created for the circulation of air in a factory, which should be maintained at a specific temperature. Walls and roofing should be made of a material that is intended for a particular temperature that shouldn’t go over as much as possible. Certain precautions must be taken to protect the employees in facilities where the manufacturing process requires extremely high or low temperatures. Dust and fume (Section 14) Every factory has to have efficient measures to remove or prevent any dust, fumes, or other impurities that might harm or offend the employees employed and cause inhalation and buildup in any workroom. No factory may operate an internal combustion engine unless the exhaust is directed outside, and no other internal combustion engine may be used. Additionally, precautions must be made to avoid the buildup of fumes that might endanger the health of any employees inside the room. Overcrowding (Section 16) There should be no overcrowding in factories that might harm the health of the workers.