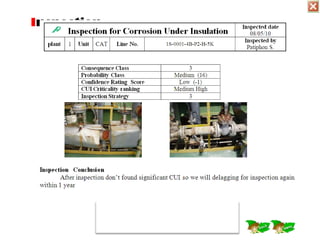

CUI (Corrosion Under Insulation) poses a significant risk to chemical plants. The presentation discusses CUI, identifying loops susceptible to CUI, and outlining a strategy to inspect for and manage CUI risks. A four-point strategy is proposed: 1) identify high risk loops, 2) perform inspections and repairs, 3) continue monitoring, and 4) update the strategy based on inspection findings. Implementing a risk-based CUI management program can increase plant reliability.