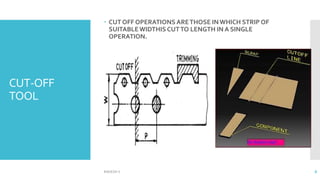

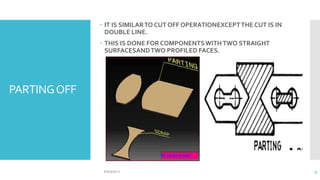

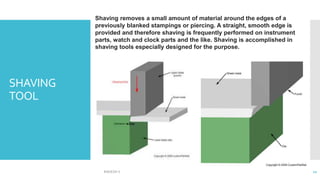

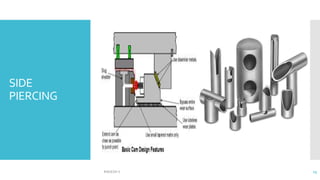

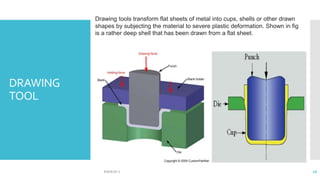

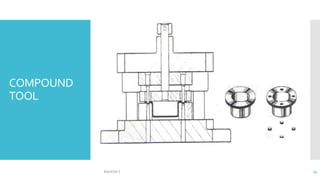

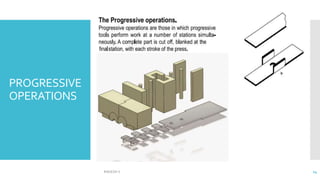

This document discusses different types of tooling used in manufacturing processes. It categorizes tooling into presses, molds, jigs and fixtures, and gauges. It then provides brief 1-2 sentence descriptions of specific tool types, including blanking, cut-off, parting-off, trimming, piercing, shaving, broaching, honing, side piercing, bending, forming, drawing, curling, bulging, extruding, cold forming, compound, progressive operations, and assembly tools. The document serves to classify and introduce different tooling used in manufacturing.