tailwater level.pdf

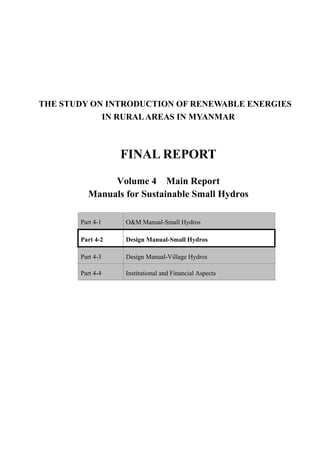

- 1. THE STUDY ON INTRODUCTION OF RENEWABLE ENERGIES IN RURALAREAS IN MYANMAR FINAL REPORT Volume 4 Main Report Manuals for Sustainable Small Hydros Part 4-1 O&M Manual-Small Hydros Part 4-2 Design Manual-Small Hydros Part 4-3 Design Manual-Village Hydros Part 4-4 Institutional and Financial Aspects

- 2. i THE STUDY ON INTRODUCTION OF RENEWABLE ENERGIES IN RURAL AREAS IN MYANMAR Final Report Volume 4 Manuals for Sustainable Small Hydros Part 4-2 Design Manual - Small Hydros TABLE OF CONTENTS 1 Investigation and Planning ...........................................................................................1 1.1 Estimate of Power Demand................................................................................1 1.2 Measurement of Discharge and Head.................................................................4 1.2 Measurement of Discharge and Head.................................................................5 1.3 Available Power Discharge...............................................................................10 1.4 Surveys for Topography and Geology..............................................................12 1.5 Layout of Power Facilities................................................................................15 1.6 Hydropower Planning.......................................................................................18 2 Design of Civil Structures ..........................................................................................22 2.1 Head Works ......................................................................................................22 2.2 De-silting Basin................................................................................................32 2.3 Power Canal......................................................................................................34 2.4 Head Tank.........................................................................................................40 2.5 Regulating Pond ...............................................................................................43 2.6 Penstock............................................................................................................47 2.7 Powerhouse.......................................................................................................53 3. Design of Generation Equipment ...............................................................................54 3.1 Turbine..............................................................................................................54 3.2 Generator ..........................................................................................................65 3.3 Control Unit......................................................................................................68 3.4 Inlet valve .........................................................................................................70

- 3. ii LIST OF TABLES Table 1.1.1 Sample of Power Demand Estimate................................................................4 Table 1.6.1 Minimum Turbine Discharge ..........................................................................19 Table 2.1.1 Various Types of Weir ....................................................................................24 Table 2.1.2 Various Types of Intake ..................................................................................28 Table 2.1.3 Hydraulic Requirements Applied to Side Intake ...........................................30 Table 2.3.1 Facilities for a Canal........................................................................................35 Table 2.3.2 Velocities for Unlined Canals .........................................................................36 Table 2.5.1 Sand Flushing Capacity of 'Saxophone' Suction Head....................................46 Table 3.1 Type of Turbines and Applicable Range............................................................55 LIST OF FIGURES Figure 1.1.1 National Grid in Myanmar.............................................................................1 Figure 1.1.2 Power Demand Categories.............................................................................1 Figure 1.2.1 Example of Discharge Measurement .............................................................5 Figure 1.2.2 Discharge Measurement by Current Meter.................................................5 Figure 1.2.3 Velocity Measurement by Current Meter ......................................................6 Figure 1.2.4 Measurement of Sectional Area and Velocity ...............................................6 Figure 1.2.5 Velocity and Depth ........................................................................................6 Figure 1.2.6 Measurement by Float....................................................................................6 Figure 1.2.7 Discharge Measurement by Weir...................................................................7 Figure 1.2.8 Water Level Gauge ........................................................................................7 Figure 1.2.9 Example of Stage-Discharge Rating Curve ...................................................7 Figure 1.2.10 Form of Discharge Measurement.................................................................8

- 4. iii Figure 1.2.11 Measurement of Discharge and Head ..........................................................9 Figure 1.2.12 Preliminary Planning of Layout Based an Q & H .......................................9 Figure 1.2.13 Measurement of Head Using Carpenter’s Level..........................................9 Figure 1.2.14 Measurement of Head Using Pressure Gauge..............................................9 Figure 1.2.15 Tools for Measurement of Head ..................................................................9 Figure 1.3.1 Use of Water ..................................................................................................10 Figure 1.3.2 Example of Available Power Discharge ........................................................11 Figure 1.4.1 Sample of GPS Mapping................................................................................13 Figure 1.4.2 Test Pit ...........................................................................................................14 Figure 1.4.3 Sample Log of Test Pit...................................................................................14 Figure 1.5.1 Relation between Length and Head ...............................................................15 Figure 1.5.2 Mini/Micro Hydro Utilizing Drops or Falls...................................................15 Figure 1.5.3 General Layout of Small Hydro.....................................................................16 Figure 1.5.4 General Profile of Open Waterway System...................................................16 Figure 1.5.5 Typical Profile of Waterway..........................................................................17 Figure 1.6.1 Small Hydro Development Pattern-1.............................................................18 Figure 1.6.2 Small Hydro Development Pattern-2.............................................................19 Figure 1.6.3 Effective Head for Impulse Turbines.............................................................20 Figure 1.6.4 Effective Head for Reaction Turbines............................................................20 Figure 1.6.5 Flow Duration Curve .....................................................................................21 Figure 2.1.1 Head Works....................................................................................................22 Figure 2.1.2 Location of Intake ..........................................................................................22 Figure 2.1.3 Tyrolean Intake ..............................................................................................23 Figure 2.1.4 Profile of Tyrolean Intake..............................................................................23 Figure 2.1.5 Sand Flush Gate .............................................................................................23 Figure 2.1.6 Weir Level......................................................................................................25 Figure 2.1.7 Weir Profile....................................................................................................25 Figure 2.1.8 Example of Rating Curve...............................................................................25 Figure 2.1.9 Flowchart to Estimate Inflow Discharge into Intake .....................................26

- 5. iv Figure 2.1.10 Sample of Intake Plan ..................................................................................29 Figure 2.1.11 Schematic Profile of Intake Structures.........................................................29 Figure 2.1.12 Front Elevation of Skimmer Wall at Entrance.............................................31 Figure 2.1.13 Trash racks ...................................................................................................31 Figure 2.2.1 De-silting Basin..............................................................................................32 Figure 2.2.2 Side Spillway .................................................................................................32 Figure 2.2.3 Sand Drain Gate.............................................................................................32 Figure 2.2.4 Overflow Discharge and Water Surface Profile in Side Spillway.................33 Figure 2.3.1 Power Canal ...................................................................................................34 Figure 2.3.2 Canal and Slope Failure .................................................................................34 Figure 2.3.3 Side Spillway .................................................................................................34 Figure 2.3.4 Existing Footpath ...........................................................................................35 Figure 2.3.5 Structure without Canal..................................................................................36 Figure2.3.6 Stone Masonry Canal......................................................................................36 Figure 2.3.7 Canal Design..................................................................................................37 Figure 2.3.8 Side Channel Spillway...................................................................................37 Figure 2.3.9 Water Surface : Uniform Flow.......................................................................37 Figure 2.3.10 Discharge Calculation..................................................................................38 Figure 2.3.11 Type of Canal Lining ...................................................................................39 Figure 2.3.12 Cross Drain under Power Canal...................................................................39 Figure 2.3.13 Cross Drain over Power Canal.....................................................................39 Figure 2.4.1 Head Tank......................................................................................................40 Figure 2.4.2 Head Tank with Spillway...............................................................................40 Figure 2.4.3 Head Tank......................................................................................................41 Figure 2.5.1 Pondage Capacity...........................................................................................43 Figure 2.5.2 Inflow Estimation...........................................................................................44 Figure 2.5.3 'Saxophone' Sand Flushing ............................................................................45 Figure 2.6.1 Penstock .........................................................................................................47 Figure 2.6.2 Water Hammer Analysis................................................................................49

- 6. v Figure 2.6.3 Head Loss.......................................................................................................50 Figure 2.6.4 Head Loss of Trashrack .................................................................................50 Figure 2.6.5 Head Loss of Penstock Inlet...........................................................................51 Figure 2.6.6 Head Loss Coefficient for Reducer................................................................51 Figure 2.7.1 Powerhouse ....................................................................................................53 Figure 3.1 Structure of Pelton Turbine...................................................................................55 Figure 3.2 Water Flow in Turgo Impulse Turbine.................................................................57 Figure 3.3 Structure of Turgo Impulse Turbine .....................................................................57 Figure 3.4 Inner Shape of Turgo Impulse Turbine.................................................................57 Figure 3.5 Installation of Turgo Impulse Turbine and Tailrace.............................................58 Figure 3.6 Structure of Cross Flow Turbine ..........................................................................59 Figure 3.7 Water Flow in Cross Flow Turbine ......................................................................59 Figure 3.8 Characteristics of Cross Flow Turbine .................................................................59 Figure 3.9 Runner Diameter and Width.................................................................................60 Figure 3.10 Draft Head of Cross flow Turbine ......................................................................61 Figure 3.11 Spiral-type Francis Turbine with Horizontal Shaft, Single Runner and Single Discharge....................................................................................................................62 Figure 3.12 Spiral-type Francis Turbine with Horizontal Shaft, Single Runner and Double Discharge....................................................................................................................62 Figure 3.13 Structure of Package-type Bulb Turbine.............................................................63 Figure 3.14 Structure of S-shaped Tubular Turbine...............................................................64 Figure 3.15 Reversible Pump Turbine ...................................................................................64 Figure 3.16 Turbine Selection Diagram.................................................................................65 Figure 3.17 Concept Figure of Dummy Load Governor........................................................68 Figure 3.18 Excitating Circuit with AVR ..............................................................................70 Figure 3.19 Structure of Butterfly Valve................................................................................71 Figure 3.20 Structure of Through-flow Valve........................................................................72 Figure 3.21 Structure of Sluice Valve....................................................................................72

- 7. vi LIST OF APENDICES (Presented in Part 6-2 of Volume 6) Appendix 1 Nomograms Appendix 2 Computer Programs Appendix 3 Sample of Design Criteria Appendix 4 Project Drawings Appendix 5 Sample Specifications (included in Database) Appendix 6 Sample of Cost Estimate for Nam Lan Hydropower Project Appendix 7 Principal Dimensions of Turbines Appendix 8 Principal Dimensions of Generators Appendix 9 Unit Conversion Table of Weights and Measures Appendix 10 Technical Terms

- 8. -1- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR 1 Investigation and Planning 1.1 Estimate of Power Demand (1) Need for Power Demand Survey There are many villages scattered around the rural areas of Myanmar, where by far the largest percentage of the population lives, that do not have electricity and where the electrification ratio has not reached 8%. Any further extension of the distribution lines from the national grid would be difficult, even to areas near the grid system, because of the shortage of generated power. In order to advance rural electrification under such circumstances, the development of isolated power systems would be more practical than extension of the power grid. Renewable energy such as small ~ micro-scale hydropower, for which the potential is abundant in the mountainous regions, would be one of the most effective sources for the areas, and the local technological expertise has been developing to some extent recently. It is essential to be able to estimate accurately the power demand for the target area when a small hydropower scheme is launched. Because hydropower is a site-specific energy, identification of hydro potentials to meet the required demand should be the basis for the planning of rural electrification. For the power supply in an isolated grid system, the power generated should be kept at a higher level than the load incurred, otherwise the following measures are needed: 1) Backup power by other power sources such as diesel generators 2) Adjustment of the power demand (2) Survey for Power Demand The power demand in the rural areas in Myanmar can be classified into the following categories according to a rural society survey conducted by the JICA Study Team in June 2001. Source: MEPE Figure 1.1.1 National Grid in Myanmar Demand Center Household Population Local Industries Public Facilities Source: JICA Study Team Figure 1.1.2 Power Demand Categories

- 9. -2- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Household use : light, TV, radio, refrigerator, rice cooker, etc. Public use : streetlight, temple/pagoda, clinic/hospital, school, etc. Industrial use : local industries, etc. An investigation of the rural society needs to be carried out at the initial stage of the planning to estimate the power demand, of which the main items are summarised as follows: a) Numbers of household and population in each village tract b) Numbers, scales, and time zone of electric appliances in home use, public use, and local industry use c) Existing power facilities and existing electrification ratio d) Future development The general information required for the planning is as follows: z Administration of the township that covers the demand centre z Location, area, and accessibility of the demand centre z Main industries z Willingness to electrification z Income and ability to pay for electricity z Possibility for rehabilitation of the existing power facilities and extension of distribution lines z Land use in the river basin, and agricultural cropping patterns z Land acquisition z Sectional map showing the village tracts The load curves for seasonal and time fluctuations of the power demand should be estimated taking into account the usage patterns of electrical facilities/appliances, ratio of concurrent use, etc. by reference to the existing records in neighbouring power stations. z Seasonal fluctuation : Agricultural processing, drying processing in monsoon regions z Time fluctuation : Lighting in night-time use, local industries in daytime use

- 10. -3- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Where electric motors are being operated, the gross power demand (Pd) for such facilities should be within a suitable range due to the inrush current required at the starting time. z Pd < (Total power output – Other demand) x 40 % The main electrification demands in home use are for lighting, TV, radio and refrigerator in that order of priority, and the averaged household demand was estimated at 120 W for lighting, and 160 W after introducing rice cookers, according to the rural survey by JICA Study Team conducted in June 2002. Local cottage industries may consist of the main demand during daytime and can be an important factor for determining the electricity tariff system, local development, and sustainable management of the VEC. An investigation is needed to determine the number of units, power consumption, operating conditions, and diesel consumption required to service the electricity powered machines being operated in existing local cottage industries. (3) Sample of Power Demand Estimate A sample of the power demand estimate for a village with 2,082 household in the Northern Shan State is shown below:

- 11. -4- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Table 1.1.1 Sample of Power Demand Estimate Customer Number Step Night Daytime of Unit Con- Sim- Unit Con-Acce Estimat-Sub-totalUnit Con-Sim- Unit Con-Acce Estimat- Sub-total Custo- sumption ulta- sumption ssibi ed Power sumption ulta- sumption ssibi ed Power mer neou lity Demand neou lity Demand Watt s % Watt % kW kW Watt s % Watt % kW kW 1.Household 2,082 1-1 130 90% 120 93 232.4 232.4 130 15% 20 93 38.7 38.7 1-2 220 70% 160 93 309.8 309.8 220 20% 50 93 96.8 96.8 2. Public 2.1 Street 16 400 50% 200 100 3.2 400 0 0 100 0.0 Light 2.2 Temple & 11 2,000 30% 600 100 6.6 2,000 40% 800 100 8.8 Pagoda 2.3 Hospital 1 230 70% 160 100 0.2 230 50% 120 100 0.1 2.4 Clinic 1 310 70% 220 100 0.2 310 50% 160 100 0.2 2.5.1 H.School 1 6,200 0 0 100 0.0 6,200 20% 1,240 100 1.2 2.5.2 M.School 0 1,640 0 0 100 0.0 1,640 20% 330 100 0.0 2.5.3 P.School 9 380 0 0 100 0.0 380 20% 80 100 0.7 Sub-total 10.2 11.0 3. Business 3.1 Restaurant 3 3,185 30% 960 100 2.9 3,185 30% 960 100 2.9 3.2 Guest House 2 4,905 50% 2,450 100 4.9 4,905 30% 1,470 100 2.9 Sub-total 7.8 5.8 4. Industry 4.1 Rice Mill 18 5,000 0 0 100 0.0 5,000 80% 4,000 100 72.0 4.2 Oil Mill 6 5,000 0 0 100 0.0 5,000 80% 4,000 100 24.0 4.3 Powder Mill 0 5,000 0 0 100 0.0 5,000 80% 4,000 100 0.0 4.4 Sugarcane 0 5,000 0 0 100 0.0 5,000 80% 4,000 100 0.0 Processing 4.5 Saw Mill 2 10,000 0 0 100 0.0 10,000 80% 8,000 100 16.0 4.6 Paper Mill 0 5,000 0 0 100 0.0 5,000 80% 4,000 100 0.0 4.7 Tofu Mf'g 3 4,000 0 0 100 0.0 4,000 80% 3,200 100 9.6 4.8 Noodle Mf'g 3 7,000 0 0 100 0.0 7,000 80% 5,600 100 16.8 4.9 Furniture 5 5,000 0 0 100 0.0 5,000 80% 4,000 100 20.0 4.10 Iron Work 5 4,000 0 0 100 0.0 4,000 80% 3,200 100 16.0 4.11 BCS 2 1,500 0 0 100 0.0 1,500 80% 1,200 100 2.4 4.12 Weaving 0 5,000 0 0 100 0.0 5,000 80% 4,000 100 0.0 4.13 Water Pump 25 200 0 0 100 0.0 200 80% 160 100 4.0 Sub-total 0.0 180.8 5. Total 5.1 1-1+2,3,4 250.3 236.4 5.2 1-2+2,3,4 327.8 294.5 6. Gross Total 6.1 1-1+2,3,4 Including 5% of transfer loss 270 Incl. 5% transfer loss 250 6.2 1-2+2,3,4 Including 5% of transfer loss 350 Incl. 5% transfer loss 310 Source: JICA Study Team z Population : 12,229 z Household : 2,082 z Existing electrification ratio : 13.6 % z Willingness to pay for initial fee : K 23,000 z Willingness to pay for monthly fee: K 680/month (surveyed in June 2001)

- 12. -5- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Source: JICA Study Team Figure 1.2.2 Discharge Measurement by Current Meter 1.2 Measurement of Discharge and Head (1) Measurement of Discharge In the rural areas of Myanmar, the existence of either discharge records or water level gauging station information is generally expected at the rivers where a small hydropower station is planned. When a small hydropower site is identified, the discharge measurement of the river through a year is preferable. It is indispensable for the planning to carry out the following: 1) Discharge measurement more than 10 times within a proper range that enable establishment of the stage-discharge rating curve at the intake site. 2) Establishment of the water level gauge, and as many as possible readings, especially during the dry season. The task of gathering such information may be sublet to the local inhabitants. . The river discharges are likely to decrease significantly in the dry season in Myanmar as compared with those in the rainy season. It is, accordingly, essential to investigate discharges, especially in the dry season, for the planning of a small hydro station with an isolated grid system to supply stable energy throughout a year. The following methods are available to measure the river discharge: 3) Current Meter Source: JICA Study Team Figure 1.2.1 Example of Discharge Measurement

- 13. -6- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR v0.6 0.6 d Current Meter Source: JICA Study Team Figure 1.2.3 Velocity Measurement by Current Meter ① ② ③ ④ ⑤ ⑥ ⑦ b v1 v2 v4 v5 v6 d1 d2 d3 d4 d5 d6 d7 d8 d9 d10 d11 v3 d11 b b b b b Source: JICA Study Team Figure 1.2.4 Measurement of Sectional Area and Velocity vs Float vm Source: JICA Study Team Figure 1.2.6 Measurement by Float This is the most common method to measure velocities where the stream is not irregular and turbulent. A location for the measurement should be selected in a straight stretch of the river. Simple measurements as below may be sufficient for streams where a small hydropower scheme is planned: i) 2-point method Vm = 1/2 x (V0.2 + V0.8) for depth > 1 m ii) 1-point method Vm = V0.6 for depth < 1 m where, Vm : mean velocity, V0.6 : velocity at 60% depth from surface. The discharge of flow can be derived using the following equation: A V Q ⋅ = 4) Float Method This is the easiest method to measure velocities in a stream without any special equipment. However, the accuracy cannot be expected where the stream is irregular, wide, and shallow. The discharge of flow is given by the following formula: A V c Q ⋅ ⋅ = Source: JICA Study Team Figure 1.2.5 Velocity and Depth d 0.2d 0.6d 0.8d V0.2 V0.6 V0.8 Vs Where, Q : discharge (m3 /s) V : mean velocity (m/s) A : cross sectional area (m2 )

- 14. -7- Nippon Koei / IEEJ Volume 4 Manuals Part 2 The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Figure 1.2.8 Water Level Gauge L > 3h > 2h > 2h h > 4h h > 2h Source: JICA Study Team Figure 1.2.7 Discharge Measurement by Weir 5) Weir Method This method requires construction of a weir across the stream to measure discharge directly in the stream. The discharge of flow is given by the following formula: 5 . 1 ) 2 . 0 ( 84 . 1 h h L Q ⋅ ⋅ − ⋅ = 6) Stage-Discharge Method This method consists of the following procedures: (i) Discharge measurement more than 10 times within the range required to establish a stage-discharge rating curve (ii) Water level gauge reading The relation between water level and discharge can be expressed by a quadratic equation. It is noted that the stage-discharge rating curve should be reviewed periodically for calibration, especially after the flood season that may result in erosion or sedimentation on the riverbed. A form for discharge measurement is shown below: Where, c =0.85 for concrete channel 0.80 for smooth stream 0.65 for shallow stream Where, Q : discharge (m3 /s) L : length of weir (m) h : overflow depth (m) Example of Stage-Discharge Rating Curve 0.00 0.25 0.50 0.75 1.00 1.25 1.50 0 5 10 15 Discharge (m3 /s) WL Gauge Reading (m) Q = 5.15H2 + 4.19H + 0.98 Source: JICA Study Team Figure 1.2.9 Example of Stage-Discharge Rating Curve

- 15. -8- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Velocit rig ban lef ban 1s 2n Av 1 Sta En Av Gau Recor Sta En Av Calc' Check DISCHARGE Measure Are (m 2 ) Tota (m 2 ) 1s Note Area 2 ) V= Rod / Wire / Boat / Bridge / Outside Dischar (m 3 ) Inside Avera dischar (m/s Are Avera depth Widt (m) Distance fro Recorded Observ Dat Measuremen Calcualte Curre mete Typ Conditi Water level Tim Discharge3 /s) Coefficie Measure Cal Resu 6 5 4 3 10 9 8 7 13 12 11 Weath Wind Wind Ave velocity No 2 Depth Velocity Velocit Measure depth Av 2n Figure 1.2.10 Form of Discharge Measurement

- 16. -9- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Head (m) Discharge (m 3 /s) Figure 1.2.11 Measurement of Discharge and Head Intake Power canal Head Tank Penstock Powerhouse Tailrace Head H (m) Discharge Q (m3 /s) Power (kW) = 9.8・Q・H・η Efficiency η = 0.5~0.7 Figure 1.2.12 Preliminary Planning of Layout Based on Q & H (2) Measurement of Head The detailed planning and design are to be made based on a topographic map with a scale of 1/500 or more, but in the preliminary planning stage, much quicker and less costly methods can be used for measurement of the head. The following tools are available to measure a head for the preliminary planning. X Y Hg Measurement of Head Using Pressure Gauge Presure Gauge Plastic Tube filled with water Figure 1.2.14 Measurement of Head Using Pressure Gauge X Y h h X1 X2 Xn hn Hg Level Measurement of Head Using Carpenter's Level Figure 1.2.13 Measurement of Head Using Carpenter’s Level Distance Meter Clinometer Figure 1.2.15 Tools for Measurement of Head Portable Compass GPS to measure coordinates & altitude Source: (Figure 1.2.11~1.2.15) JICA Study Team

- 17. -10- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Irrigated Area Irrigation Canal Powerhouse Intake Source: JICA Study Team Figure 1.3.1 Use of Water 1.3 Available Power Discharge If paddy fields with single-cropping are developed in a river basin whose water is utilised for power generation, the irrigation water supply usually starts in May when the river discharge is at the minimum level in the end of the dry season. Therefore, the available discharge in May is likely to become the lowest under such circumstances. The first priority for water utilisation is generally given to the irrigation supply in rural areas in Myanmar. It is therefore required to investigate not only the river discharge, but also the existing water utilisation, irrigation system, and rainfall patterns to estimate the available power discharge. The following items need to be surveyed at the planning stage: z Land utilisation in the areas affected by a hydropower station z Irrigation area, the cropping patterns, and the irrigation supply discharge z Future development plan for irrigation z Basic stance of local inhabitants for the water utilisation When the water use produces a conflict between irrigation and power generation demands, the following needs to be considered: 1) The location of the power generation facilities should be carefully selected to minimise the conflict between irrigation water use and power discharge in the area where the river flow is utilised for the irrigation in the river stretch between the intake and the tailrace. 2) The river discharge and the irrigation demand in the areas affected by the hydropower plant should be investigated throughout one year to estimate the available power discharge, taking into account the existing irrigation practices. 3) Irrigation water for paddy fields is approximately 1.0 m3 /s for 1,000 ha in general. Areas, cropping patterns, irrigation canal systems, return flow into the river, rainfall and supplemental discharge from the river are major factors to estimate the irrigation demand.

- 18. -11- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Discharge at Hosang Chaung in 2001 - 2002 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 5 6 7 8 9 10 11 12 1 2 3 Q (m3 /s) 4 Irrigation Requirement River Discharge Available discharge for power generation 4 5 2001 2002 Source: Measurement and Assumption of JICA Study Team Figure 1.3.2 Example of Available Power Discharge

- 19. -12- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 1.4 Surveys for Topography and Geology (1) Topography An Inch-mile map (1:63,360) is suitable to identify a hydropower scheme site for the initial planning and to determine accessibility from the demand centre. The use of a portable GPS may be a powerful tool to position easily and accurately the specific points in and around the project area at the initial planning stage. A sample mapping by GPS is shown figure in the next page. It is essential for the detailed design and construction to map the topography of the anticipated construction areas that will cover the open civil structures such as intake, de-silting basin, head tank, and powerhouse at a 1:500 scale or larger, based on a topographic survey. As for power canals, the profile and cross sectional surveys may be enough for the design, but further mapping of the areas around the related structures such as cross drains, side spillways, siphons, etc. will be required.

- 20. -13- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Namlan Mini-Hydro Development Plan 15.4 15.6 15.8 16.0 16.2 16.4 16.6 16.8 17.0 23.0 23.2 23.4 23.6 23.8 24.0 24.2 E (97deg xx min) N (22deg xx min) about 370 m about 344 m Kyutaw Bridge to Hsipaw to Nam Lan Kyutaw Chaung Nam Pankan Chaung Hosang Chaung Hosang Intake Site Cart Track No.2 Diversion Channel from Nam Pankan to Hosang No.1 Diversion Channel from Kyutaw to Nam Pankan No.1 Branch point No.2 Branch point No.3 Branch point No.4 Branch point Sink Hole Head Pond Powerhouse Hosang Village Kyutaw Chaung Branch Irrigation canal from Kyutaw Chaung No.2 Diversion about 650 m Nam Pankan about 1,100 m No.1 Diversion about 750 m Nam Pankan Bridge Kyutaw Village Source: Field Study of JICA Study Team Figure 1.4.1 Sample of GPS Mapping

- 21. -14- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Figure 1.4.2 Test Pit (2) Geology Test pitting is enough to confirm the foundation geology of the key structures for small hydropower schemes. A practical pit size is 1.8 m long x 1.2 m wide x 5.0 m deep. It can be manually dug with scoops and picks, using a rope and bucket to lift up the excavated soil without the use of any further heavy lifting equipment. A pit log should be prepared for every test pit, as a report of the test pitting, and should contain the pit number, its location, boundaries and depths, description of soil, groundwater table and bedrock surface, if any, and all other relevant information. Source: JICA Study Team Figure 1.4.3 Sample Log of Test Pit

- 22. -15- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Figure 1.5.2 Mini/Micro Hydro Utilizing Drops or Falls Tributary Potential Site-1 Potential Site-2 L1 L2 H1 H2 L / H < 40 General outline L / H < 20 Advantageous sheme L / H < 15 Excellent scheme where L : length of waterway H : head Main stream Source: JICA Study Team Figure 1.5.1 Relation between Length and Head 1.5 Layout of Power Facilities Selection of Site Attention should be paid to the following points to identify the potential for a small hydropower scheme with an isolated grid system: 1) Discharges are stable even in the dry season. 2) Specific discharge (m3 /sec / 100 km2 ) is big. 3) (L/H) rate is small 4) Distance from demand centre is short. Basic Layout The main components of the civil facilities are weir, intake, de-silting basin, power canal, head tank, pondage, penstock, powerhouse, and tailrace. It is rare for dam type power generation or tunnel waterway types to be adopted in a small hydropower facility. However, existing irrigation dams may be utilised for small/mini hydropower in a re-development plan. The existing irrigation canals with drops may be utilised for mini/micro hydropower. Penstock pipes can be connected to the intake or the de-silting basin without provision of a power canal. In such a case, since all or part of the irrigation water is to be used for power generation, the discharge fluctuation during irrigation and non-irrigation periods needs to be confirmed. Depending on the nature of the work and the design conditions involved, the combination of facilities may be varied. As have been experienced in many small hydropower plants constructed, the major issues relating to the civil components are i) sedimentation, and ii) hydraulic characteristics during floods. Therefore, suitable combinations and layouts responding to the specific site conditions need to be

- 23. -16- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 properly reflected in the design. A typical layout and profile of a small hydropower station is shown below together with technical notes: Weir River Outlet / SandFlush Gate Spillway Power Canal HeadTank SandDrain Gate Spillway Trashracks Intake Intake Gate Trashracks SandDrain Gate De-silting Basin Side Spillway Source: JICA Study Team Figure 1.5.4 General Profile of Open Waterway System De-silting basin z velocity < 0.3 m/s z slope steeper than 1/30 Power canal slope 1/500 ~ 1/2,000 Power Canal De-silting Basin Intake Head Tank Penstock Powerhouse Source: JICA Study Team Figure 1.5.3 General Layout of Small Hydro z De-silting basin to be located next to intake z Low velocity to regulate excessive flow & sand z Steep slope enough to wash out sediment to river z Intake to be located in a straight river stretch z Side intake with weir or Tyrolean intake z Sand flushing gate to be provided beside the weir Slope protection or box culver Cross drain at valley Nearby demand center

- 24. -17- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Penstock TWL Anchor Block Spillway HeadTank SandDrain Gate Trashracks Powerhouse Tailrace Source: JICA Study Team Figure 1.5.5 Typical Profile of Waterway Penstock z to avoid potential land slide area z to be located on stable ridge z to be located below hydraulic grade line z slope protection & drain along penstock z penstock directly from de-silting basin may be possible according to topography Powerhouse z to be built on firm foundation z to be located above FWL z drainage around Head Tank z to be located on stable ridge z capacity against load change z spillway & sand drain

- 25. -18- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 1.6 Hydropower Planning (1) Design Discharge For a small hydropower station with an isolated grid system, the power generated should be above the load demanded when a backup power system cannot be provided. The main points for planning of such a small hydro plant are summarised as follows: 1) determination of the minimum power discharge based on the available minimum discharge for power generation ( 90 ~ 95% dependable discharge is a general target) 2) determination of the maximum power discharge depending on the peak load demand and the available discharge during the rainy season. Min. Discharge 10 8 9 11 12 1 2 3 4 5 6 7 Non - Operation Period Firm Power Output Output (kW) Demand Qmin Potential (Q min ) > Demand Spill out Irrigation Discharge Q (m 3 /s) Source: JICA Study Team Figure 1.6.1 Small Hydro Development Pattern-1

- 26. -19- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Ratios of (minimum turbine discharge)/(maximum turbine discharge) and (minimum efficiency)/(maximum efficiency) are given for typical turbines below: The numbers of turbines for a small hydropower plant are preferably 1 unit, or 2 units to cover the wide range of discharge fluctuation. When turbines without discharge control such as Reverse Type are adopted, several units may be installed to respond to available discharges in the rainy and dry seasons. The number of units required is closely related to the selection of turbine type as explained later. (2) Effective Head Effective head can be calculated by deducting the head losses from the gross head between the intake and the tailrace. However, the effective head for impulse turbines Table 1.6.1 Minimum Turbine Discharge Type (Qmin / Qmax) (η min / η max) Francis with horizontal shaft 30 ~ 40% 0.70 Pelton with horizontal shaft 15% 0.75 2-nozzle Pelton with horizontal shaft 30% 0.90 1-nozzle Cross flow 15% 0.75 guidevane divided Cross flow 40% 0.75 guidevane not divided Turgo impulse 10% 0.75 2-nozzle Turgo impulse 20% 0.75 1-nozzle Reversed Pump 100% Source: Estimation by JICA Study Team Min. Discharge 1 2 3 4 10 11 5 6 7 8 9 12 Discharge Q (m 3 /s) Output (kW) Qmax Qmin Non - Operation Period Spill out Max. Power Output Min. Power Output Potential (Q min ) < Demand Demand Peak power operation or Demand Control Max. Power Output for 24-hour ① 24 hours Supply with Min. Power or ② Peak Power Operation Irrigation Source: JICA Study Team Figure 1.6.2 Small Hydro Development Pattern-2

- 27. -20- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 (Pelton, Turgo Impulse, Cross Flow) and that for reaction type turbines (Francis, Propeller, Tubular) are calculated differently as shown below: Detailed calculation method for head losses are shown in Chapter 2.6 and Appendix 2-3 of Part 6-2 in Volume 6. h1 h3 Hg He h2 FSWL TWL v1 v1 2 /2 v2 2 /2 v2 Head Tank Penstock Powerhouse Tailrace Hg : gross head (m) He : effective head (m) h1 : head loss between Intake & head tank h2 : head loss between head tank & tailrace h3 : head between draft tube WL and TWL Intake 3 2 2 2 1 2 h g v h h H H g e − − − − = Source: JICA Study Team Figure 1.6.4 Effective Head for Reaction Turbines v1 2 /2 v1 h1 h3 Hg He h2 FSWL TWL Hg : gross head (m) He : effective head (m) h1 : head loss between Intake & head tank h2 : head loss between head tank & tailrace h3 : head between mean pitch level and TWL Intake Penstock Powerhouse Tailrace Head Tank 3 2 1 h h h H H g e − − − = Source: JICA Study Team Figure 1.6.3 Effective Head for Impulse Turbines

- 28. -21- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Source: JICA Study Team Figure 1.6.5 Flow Duration Curve (3) Power Output and Annual Energy Power output is given by the following formula: H Q P ⋅ ⋅ ⋅ = η 8 . 9 where, P :Power output (kW) η :combined efficiency for turbine and generator Q :power discharge (m3 /s) H :effective head (m) If a run-of-river scheme requires a flow of more than the minimum river discharge, a flow duration curve is useful to estimate the approximate annual energy as follows: For maximum discharge Q1 : Annual Energy E1 = ξ1 · P · 8,760 Where, E1 : Annual energy (kWh) P : Max. power output (kW) For maximum discharge Q2 : Annual Energy E2 = ξ2 · P · 8,760 When a bigger discharge (Q1) is selected, a larger scale of power facility with a lower plant factor is required, while a smaller discharge (Q2) gives a smaller plant facility with a higher plant factor. The optimum maximum design discharge to be finally selected should take into account the revenue generated and the cost incurred in principle, bearing in mind that the power tariff needs to be properly established. ) ' ' ( ) ' ' ( ) ( 1 BGI A area BCDF A area r PlantFacto = ξ ) ( ) ( ) ( 2 ABGI area ABCDF area r PlantFacto = ξ

- 29. -22- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Sandbar River × Intake (C) ○ Intake (A) × Intake (B) Source: JICA Study Team Figure 2.1.2 Location of Intake 2 Design of Civil Structures 2.1 Head Works Site Selection z This section deals with run-of-river schemes that do not require dam construction, but employ a diversion structure or weir across the river. z One of the most common problems affecting a small/mini/micro hydropower scheme is the damage to the intake caused by floods, and another is sedimentation deposited upstream of the intake or flowing into the waterway. The following points are to be considered in locating the intake structures: 1) Intake (A): The best location for an intake is to locate it along a relatively straight stretch of the stream 2) Intake (B): Susceptible to severe damage from floods, debris, and erosion 3) Intake (C): Sediments tend to accumulate in front of the intake and can enter and/or block the intake Weir SandFlush Gate Spillway Power Canal HeadTank SandDrain Gate Spillway Trashracks Intake Intake Gate Trashracks SandDrain Gate De-silting Basin Side Spillway Source: JICA Study Team Figure 2.1.1 Head Works

- 30. -23- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Source: JICA Study Team Figure 2.1.4 Profile of Tyrolean Intake Figure 2.1.3 Tyrolean Intake Countermeasures against Sedimentation z The Tyrolean intake is applicable to mini/micro hydropower stations located on steep rivers containing boulders and pebbles. The characteristics of Tyrolean type intake are as follows: 1) Intake facilities can be minimised. 2) Relatively large amounts of sediment will enter the intake especially during a flood, so a sand drain facility with enough hydraulic gradient and capacity to drain out the sediment is indispensable. Periodical sand draining operations are required. 3) Cleaning work for driftwood or leaves trapped on the screen is necessary. 4) An intake discharge of 0.1 ~ 0.3 m3 /s/m2 , a screen slope gentler than 30° and a screen bar interval of 20 ~ 30 mm is generally practised. z A sand flush gate should be located to one side of the weir to release sediments deposited upstream of the weir. The intake is located at a side of the river just upstream of the weir and to minimise sand volume entering the intake. The sill level of a sand flush gate is generally set at 0.5 ~ 1.0 m higher than the original riverbed level and 1.0 ~ 1.5 m lower than the intake floor level. z The skimmer wall at the entrance of the inlet may be effective to prevent driftwood or an excessive flood flow from entering the intake. z If slope failures or sediment yield are confirmed in the upstream basin, Weir Intake De-silting Sand Flush Gate Flow Intake Flood Water Level Weir Crest Weir Sand Flush Gate Intake Int Ga EL.2 EL.3 Trashracks Skimmar Wall 1.0 ~ 1.5 m Sand Flush Gate Source: JICA Study Team Figure 2.1.5 Sand Flush Gate

- 31. -24- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 protection work such as a gabion wall may be effective to control the sediment outflow. z Flow velocity at the intake should be limited to 0.5 ~ 1.0 m/s to avoid sediment flowing into the waterway. Weir z Types of weir are summarised as follows: Table 2.1.1 Various Types of Weir Type of Weir Specific Features Typical Figure Concrete gravity z Applicable on rock foundations z Most commonly used z Durable and impervious z Relatively high cost Floating concrete weir z Applicable on gravel foundations z Need an enough seepage path z Durable z Relatively high cost Gabion covered with concrete z Applicable on gravel foundation z Surface protection by concrete z Relatively low cost Gabion z Applicable on gravel foundation z Flexible z Low cost and easy maintenance Stone masonry z Applicable on gravel foundation z Low cost and easy maintenance Source: JICA Study Team

- 32. -25- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 WL - Discharge Curve for Spillway Discharge & Inflow into Intake 691.2 691.4 691.6 691.8 692.0 692.2 692.4 692.6 692.8 693.0 0.0 2.0 4.0 6.0 8.0 10.0 Discharge (m3 /s) WL. (m) Inflow into Intake Flow over Spillway Source: JICA Study Team Figure 2.1.8 Example of Rating Curve It should be noted that type of weir to be applied should be determined according to the power scale, importance, flood discharge, foundation condition, and maintenance requirements. The use of high quality materials and construction techniques will result in less maintenance and repair work over the life of the scheme. z The weir crest level of is normally designed equal to the Full Supply Water Level (FSWL) under the maximum design discharge. z The hydraulic design of weir and intake should be made appropriately to take the proper discharge into the waterway. Since the flow taken from a river is not regulated in a run-of-river scheme, any excessive water above the maximum design discharge should be released safely from spillways. When a weir crest is set equal to the FSWL at the maximum design discharge, the inflow into the intake can be divided into the following cases: 1) (River flow) < (Maximum design discharge) ¾ Whole flow enters the intake. ¾ The water level varies between FSWL (EL.1) and the intake floor level (EL.2) ¾ The maximum design discharge flows into the intake at FSWL. ¾ The minimum flow to the downstream basin shall be released from the river outlet at any conditions if need be. 2) (River flow) > (Maximum design discharge) ¾ A water level is above FSWL (EL.1), when a part discharge is spilt over the weir and the remainder, that exceeds the maximum design discharge, enters the waterway. ¾ Any excessive discharge taken from the intake should be released from a side spillway , which needs to be provided at a suitable location of the waterway. B H FSWL FWL SandFlush Gate EL.3 Spillway Weir EL. 2 EL. 1 Source: JICA Study Team Figure 2.1.6 Weir Level EL. 3 Intake EL. 4 H SpillwayEL.1 FWL Weir Profile Intake Source: JICA Study Team Figure 2.1.7 Weir Profile

- 33. -26- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 ¾ The intake gate should be closed during a flood to avoid excessive sediment inflow into the waterway. z If a river water level is known from readings of a water level gauge provided at the forebay, a discharge entering the waterway can be estimated by the following sequences. Then, a rating curve (WL-Q) at the forebay can be prepared. z Overflow discharge from spillway and outflow discharge through sand flush gate can be calculated by the following formulas: Discharge from a weir spillway where, Qspill : discharge from spillway (m3 /s) B : width of spillway (m) H = WL - Crest Level (m) Discharge from a sand flush gate 1) For orifice flow Q : discharge through the gate (m3 /s) A : Flow area (m2 ) H = WL – Centre level of orifice (m) 5 . 1 84 . 1 H B Qspill ⋅ ⋅ = H g A Q ⋅ ⋅ ⋅ ⋅ = 2 6 . 0 WLforebay is known WL > FSWL Overflow Discharge fromWeir Qweir = C B (WL - FSWL) 1.5 Sequence to Estimate InflowDischarge into Intake Whole flow enters the Intake Yes No Assume Discharge Qintake Non-uniformflow analysis fromHead Tank to Intake WL > Spillway Crest Yes No Calculation for Overflow Discharge fromSide Spillway No Overflow from Side Spillway WLintake = WLforebay Assumption Qintake is correct Yes No Source: JICA Study Team Figure 2.1.9 Flowchart to Estimate Inflow Discharge into Intake

- 34. -27- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 2) For pipe flow fe : loss coefficient for entrance (0.1 ~ 0.5) f : loss coefficient for friction = 124.5n2 L/D(4/3) z In order to carry out the peak power generation in the dry season without providing a regulating pond, a river channel storage may be effective if gates are provided on the weir. The gates should be open in the rainy season and be closed in the dry season if floods are not anticipated. Intake z Types of intake are summaried as follows: f f H g A Q e + + ⋅ ⋅ ⋅ = 1 2

- 35. -28- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Table 2.1.2 Various Types of Intake Type of Intake Specific Features Typical Figure Side Intake with Weir z Most commonly used for run-of-river type power schemes z Sand flush gate is located aside the weir to release sediments deposited upstream of the weir. z Intake is located at a side of the river just upstream of the weir/sand flush gate. z Intake gate is provided at upstream section of de-silting basin to close during sand drain operation or maintenance of the waterway. Tyrolean Type Intake z Suitable for steep rivers containing boulders z Weir is not necessary z Necessary to remove drift woods or leaves on the screen z Necessary to remove fine sands entered the intake Intake to Utilise Pondage z Applied to natural/artificial ponds to utilise the water for power generation Source: JICA Study Team z The site selected for the headworks should be stable and suitable for reliable foundations. All excess water and debris taken from the river needs to be minimised in the design of headworks, and those entering during a flood flow need to return to the river before entering the canal or penstock. Weir SandFlush Gate Intake Weir Intake De-silting Basin Sand Flush Gate Side Spillway Waterway Flow Intake Gate

- 36. -29- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Hydraulic requirements generally applied to side intake with concrete weir are summarised as follows: Flood Water Level Weir Crest EL.5 Weir Sand Flush Gate Intake De-silting Basin Side Spillway Power Canal Sand Drain Gate Intake Gate Schematic Profile of Intake Structures EL.2 EL.3 1 : n1 EL.6 EL.7 1 : n2 Trashracks Skimmer Wall Source: JICA Study Team Figure 2.1.11 Schematic Profile of Intake Structures Sample of Intake Plan Weir Sand FlushGate De-silting Basin Side Spillway Power Canal Sand Drain Gate Intake Gate Intake Flow Source: JICA Study Team, arranged from DHP drawing. Figure 2.1.10 Sample of Intake Plan

- 37. -30- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Table 2.1.3 Hydraulic Requirements Applied to Side Intake Item General Application Symbol Crest Level of Intake Weir = Full Supply Water Level EL. 1 Sill Level of Sand Flush Gate = Original River Bed + (0.5m ~ 1.0m) EL. 2 Floor Level of Intake = EL.2 + (1.0m ~ 1.5m) EL. 3 Velocity at Intake 0.5 ~ 1.0 m/sec approximately Top of Intake Deck = Flood Water Level + freeboard ( > 1.0m) EL. 4 Top of Intake Gate = FSWL Velocity at Intake Gate 1.0 ~1.5 m/sec approximately Crest of Side Spillway = FSWL - (0 ~ 10 cm) EL. 5 Slope of De-silting Basin 1:10 ~ 1:30 Velocity in De-silting Basin < 0.3 m/sec Length of De-silting Basin (2 ~ 3) x depth x velocity / sedimentation rate = (2 ~ 3) x depth x 0.3 / 0.1 = (6 ~ 9) x depth EL. of Sand Drain (Sand drain outlet level) > (Water level of the river) EL. 5 Floor Level of Power Canal = EL. 3 EL. 7 Slope of Power Canal 1:1,000 ~ 1:2,000 Velocity in Power Canal < 2 m/s maximum for lined canal Source: JICA Study Team

- 38. -31- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 FSWL FWL Skimmer Wall v = 0.5 ~ 1.0 m/s Source: JICA Study Team Figure 2.1.12 Front Elevation of Skimmer Wall at Entrance Flow θ b b t Thickness t = 5 ~ 9 mm Width w = 50 ~ 120 mm Interval b = 100 ~ 150 mm Inclination θ = 60 ~ 70º w Source: JICA Study Team Figure 2.1.13 Trashracks A skimmer wall at the entrance of the intake will be effective not only to avoid driftwood entering or debris floating into the intake, but also to restrict an excessive inflow by making an orifice flow when the river water level is higher than the Full Supply Water Level (FSWL) during a flood. An intake gate is provided at the upstream section of the de-silting basin that can be closed during the sand drain operation or maintenance of the waterway. The gate is to be closed during floods to avoid excessive sediment inflow. The velocity through the intake gate opening should be limited to about 1.0 m/s. Trashracks are provided at the entrance of the intake to prevent trash, leaves, and floating debris from entering the waterway. The screen bars are generally arranged with 5 ~ 9 mm thick, 50 ~ 120 mm bar wide, 100 ~ 150 mm intervals, and 60 ~ 70ºangle to the horizontal.

- 39. -32- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Side Spillway Intake Gate 1 : 10 ~ 1 : 30 Trashracks h Ls L v < 0.3m/s u Slope 1 : 10 ~ 1 : 30 Side Spillway Source: JICA Study Team Figure 2.2.1 De-silting Basin 2.2 De-silting Basin z The de-silting basin is designed to settle sands bigger than 0.5 ~ 1.0 mm diameter of which the settling velocity corresponds to 0.1 m/s. Average flow velocity in a de-silting basin is generally 0.3 m/s, and the channel slope is 1/10 ~ 1/30. The length of de-silting basin is given by the following empirical formula: where, L : length of de-silting basin (m) hs : depth of de-silting basin (m) v : average velocity in de-silting basin (m/s) = Q / (B x hs) = 0.3 m/s u : settling velocity for target sand particle (m/s) = 0.1 m/s for sand grains of 0.5 ~ 1.0 mm A side spillway should be provided at the de-silting basin to release an excessive inflow during a flood. The length required to overflow the excessive discharge and the water surface profile can be computed by the following De-Marchi’s equations: s h u v L ⋅ = ) 3 ~ 2 ( Sand Drain SandDrain Gate Side Spillway Source: JICA Study Team Figure 2.2.2 Side Spillway Source: JICA Study Team Figure 2.2.3 Sand Drain Gate

- 40. -33- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 It is noted that the outflow path needs to be protected against scouring. Source: JICA Study Team Figure 2.2.4 Overflow Discharge and Water Surface Profile in Side Spillway )} ( ) ( { 84 . 1 2 0 1 H h H h B g L φ φ − ⋅ = 2 / 1 1 2 / 1 ) ( tan 3 ) ( 3 2 w h h H w h h H w H w H − − − − − − − = − φ 2 / 3 ) ( 84 . 1 w h q − ⋅ − = Where q : unit overflow discharge (m 3 /s/m) h : depth of flow (m) B : width of channel w : height of weir (m) h 0 : depth at downstreamsection (m) h 1 : depth at upstreamsection (m) H = h + Q 2 /{2g (B h ) 2 } (m) L Flow h0 h1 h w x 0 B OverflowDischarge & Water Surface Profile in Side Spillway

- 41. -34- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 2.3 Power Canal Route Selection z This section deals with open canals only, which are most commonly applied to small/mini/micro hydropower schemes, especially in Myanmar. z A route for the power canal needs to be selected after consideration of the topographic features along the canal for the following points: 1) Stability against slope above and/or below the canal 2) Specific conditions such as streams, roads, and the existing structures to be crossed z Selection of the canal route and the design of canals should be made in consideration of the fact that the water level in a canal may rise for any of several possible reasons: 1) When the canal flow is obstructed by a landslide or closure of a gate at the downstream facilities 2) When excessive water enters the intake during a flood. 3) When excessive running water is drained into the canal during heavy rain . Weir SandFlush Gate Spillway Power Canal HeadTank SandDrain Spillway Trashracks Intake Intake Trashrack SandDrain De-silting Basin Side Spillway FSWL B Source: JICA Study Team Figure 2.3.1 Power Canal Debris Sliding of slope by overflow Sliding may be induced by overflow from a canal in which debris enters the canal. Source: JICA Study Team Figure 2.3.2 Canal and Slope Failure Side spillway to overflow excessive inflow Source: JICA Study Team Figure 2.3.3 Side Spillway

- 42. -35- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 z The following facilities for a canal may need to be designed for the above conditions: Table 2.3.1 Facilities for a Canal Potential Landslide (a) Box culvert or canal cover (concrete/wood) (b) Slope protection by structural reinforcement of the slope, excavation in a gentler slope, and vegetation such as sodding or planting Crossing of stream or valley (a) Aqueduct to by-pass the flows from a flood or debris flow (b) Siphon to path under the stream (c) Drainage facilities to collect the running water in the catchment basin and to release it safely to protect the canal from being attacked or eroded by the drained flow or debris Crossing of roads or existing structures (a) Box culvert or bridge to connect the existing road. (b) Steel pipe or concrete conduit embedded under the existing structures. Excessive inflow (a) Side spillway to overflow the excessive flow over the max. design discharge. An appropriate protection work against scouring by the overflow is indispensable (b) Drainage facilities to avoid excessive inflow into the canal Source: JICA Study Team z When selecting the canal route, the existing structures such as foot pass and irrigation channel can be utilised to minimise the construction cost of the canal as well as ease of access. z Depending on the topographic conditions, it may be possible to omit the power canal and the penstock may be connected directly to the de-silting basin or the head tank. Existing footpath or irrigation canal may be utilized for power canal Source: JICA Study Team Figure 2.3.4 Existing Footpath

- 43. -36- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Vmin = 0.3 m/s for sedimentation for flow carrying silty water Vmin = 0.3 ~ 0.5 m/s for sedimentation for flow carrying fine sand Vmin = 0.7 m/s to prevent aquatic plants Canal Dimensions z Power canals are to be designed in consideration of 1) flow capacity, 2) velocity, 3) roughness, 4) slope, 5) sectional shape, 6) lining (with or without, material), and 5) maintenance. z The velocity in a canal should be low enough to prevent erosion of the canal, especially if it is unlined, and to keep effective head as high as possible. z The velocity in a canal should be high enough to prevent sedimentation and to avoid the growth of aquatic plants especially in unlined earth canals. z Maximum permissible velocities for unlined canals to avoid erosion are given as follows: Table 2.3.2 Velocities for Unlined Canals Material n Vmax (m/s) Permeability (x 10-6 m3 /s/m2 ) Fine sand 0.020 - 0.025 0.3 – 0.4 > 8.3 Sandy loam 0.020 - 0.025 0.4 – 0.6 2.8 – 8.3 Clayey loam 0.020 - 0.025 0.6 – 0.8 1.4 – 2.8 Clay 0.020 - 0.025 0.8 – 2.0 0.3 – 1.4 z For a lined canal, wear of abrasion sets the upper limit on velocity. Velocities above 10 m/s will not damage a concrete lined canal when the water is clear, but velocities above 4 m/s containing sand and gravel may scour the lining. z The steeper the slope of the canal, the smaller the sectional area required; however the effective head is decreased. The best combination of a canal size and a slope should be examined within a suitable range of flow velocity. z The maximum velocity in a lined canal is normally smaller than 2.0 m/s. Omission of canal, and utilization of existing structures Figure 2.3.5 Structure without Canal Source: JICA Study Team Figure2.3.6 Stone Masonry Canal Stone-masonry canal with screen

- 44. -37- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 B Source: JICA Study Team Figure 2.3.8 Side Channel Spillway z A canal slope, depending on the topographic conditions, is generally as follows: 1/500 ~ 1/1,000 : to minimise the canal size in high head plant 1/1,000 ~ 1/1,500 : general application 1/1,500 ~ 1/2,000 : to minimise a head drawdown in low head plant z Roughness coefficient “n” is an empirical measure of surface roughness of a waterway. The following values are usually applied : Steel : 0.012 ~ 0.013 Concrete : 0.014 ± 0.001 Stone-masonry : 0.016 ~ 0.020 z For unlined canals, a trapezoid cross-section is the most common. Side slopes of a canal are 1.0 (V):0.5 (H) for rock foundation, and 1.0(V):2.0(H) for sandy loam foundation. z For lined canals, a rectangular or a trapezoid cross-section is commonly used for stone masonry lining, and a rectangular section for concrete lining. z A side channel spillway is generally provided at the de-silting basin and the head tank; however, it may be necessary to be designed in a suitable section of the power canal depending on the design conditions. The outflow path needs to be protected against scouring. Water Surface Profile z The canal floor elevation at the downstream end (EL.4 in the figure) is commonly fixed to provide a uniform flow depth for the maximum design discharge when the water level in the head tank or the regulating pond is at the Full Supply Water Level (FSWL). In this condition, the flow depth in the canal is uniform over the whole stretch if the canal slope is uniform. Power Canal HeadTank EL. 4 FSWL Uniform depth for design discharge Uniform flow state at the downstream end of the canal at FSWL Source: JICA Study Team Figure 2.3.9 Water Surface : Uniform Flow Properly designed lined canal reduces the canal size and the excavation volume to convey the same discharge Source: JICA Study Team Figure 2.3.7 Canal Design

- 45. -38- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 z A non-uniform flow analysis should be carried out in the full section of the waterway starting from the head tank or the regulating pond up to the intake, varying parameters such as discharge, roughness coefficient, and the initial water level at the head tank. The wall height of the canal is to be designed so that the energy line for the maximum inflow into the canal should be lower than the wall crest. z Uniform flow depth in a canal can be calculated by Manning’s Formula: Uniform flow analyses can be made by the computer programs attached in Appendix 2-1. z Non-uniform flow analysis involves solving the following differential equation: Non-uniform flow analysis can be made by the computer programs attached in Appendix 2-2. Lining Types z The lining type of earth canal has the following characteristics: (a) easy for construction and maintenance, (b) low cost, (c) not applicable to pervious and erosive foundation, (c) velocity < 0.3 m/s, (d) roughness coefficient n = 0.014 on an average, seepage loss = 1.0 (clay) ~ 8.0 (sand) x 10-6 m3 /s/m2 z The lining type of stone masonry canal has the following characteristics:(a) easy for construction and maintenance, (b) velocity <1.5 m/s (dry stone masonry) and velocity <2.0 m/s (wet stone masonry), (c) roughness coefficient n = 0.032 (dry stone masonry) and roughness coefficient n = 0.025 (wet stone masonry) h A gA Q A Q R n x b b A gA Q i dx dh ∂ − − ∂ ∂ ∂ ∂ + = α α α 3 2 2 3 4 2 3 2 1 ) ( For a rectangular section For a triangular section where, Q : discharge (m 3 /s), n : roughness coefficient, b : width of canal (m) h : depth of flow (m), R : hydraulic radius (m), I : slope of canal 2 1 3 2 I R n A Q = A V Q ⋅ = h b A ⋅ = b h h R 2 1+ = ) ( mh b h A + = 2 1 2 ) ( m h b mh b h R + + + = h b h 1 m b Source: JICA Study Team Figure 2.3.10 Discharge Calculation

- 46. -39- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Flow & Debris Power Canal Source: JICA Study Team Figure 2.3.12 Cross Drain under Power Canal Power Canal Source: JICA Study Team Figure 2.3.13 Cross Drain over Power Canal z The lining type of concrete lining canal has the following characteristics: (a) durable, (b) relatively high cost, (c) velocity < 3.0 m/s, (d) roughness coefficient n = 0.015 on an average. Cross Drain If a power canal passes through valleys with catchment areas, drain facilities that cross under or over the power canal should be provided to protect the canal structure from attack from running water with containing debris during rainfall. Box culverts, concrete pipes, polyethylene pipes, etc. are used as under drains, and open chutes as over drains. Under drains need adequate flow area, since they are likely to be clogged with debris, soil, etc. A minimum inner space of 60 cm is preferable for manual cleaning. z Slope steeper than 1/50 z Size bigger than φ 60cm z Enough flow area not to be clogged z Maintenance for clogging Stone Masonry Canal Concrete Canal Earth Canal Source: JICA Study Team Figure 2.3.11 Type of Canal Lining

- 47. -40- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Source: JICA Study Team Figure 2.4.2 Head Tank with Spillway 2.4 Head Tank Site Selection z A head tank is provided between a power canal and a penstock pipe to adjust a turbine discharge corresponding to the load fluctuation, while a surge tank is required when a pressure tunnel or conduit is applied as headrace. When a penstock pipe is connected directly to a de-silting basin, a de-silting basin may be designed to have functions of a head tank. z The location of a head tank is selected generally to be on a ridge with firm foundations, depending on the topographical and geological conditions. z A spillway and a sand drain gate should be considered and incorporated into the head tank. z When a spillway is provided (it may be omitted under some conditions), the route of the spillway should be properly designed so as to not cause sliding or erosion of the slope. Hydraulic Design z The capacity of the head tank is determined according to the responsive characteristics of the governors installed in the power plant. 1) Mechanical governors and manual operation Where, V : capacity of tank (m3 ) A : surface area of tank (m2 ) Qmax : max.design discharge (m3 /s) V > (Qmax) x (120 ~ 180) Weir SandFlush Gate Spillway Power Canal HeadTank SandDrain Spillway Trashracks Intake Intake Trashrack SandDrain De-silting Basin Side Spillway FSWL B Source: JICA Study Team Figure 2.4.1 Head Tank

- 48. -41- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Where, Q : spill-out discharge (m3 /s) Bs : length of spillway (m) H : overflow depth (m) 2) Electric governor, computer governor and dummy load governor z Spillway discharge can be calculated as follows: z A discharge capacity of sand drain gate is calculated by the following formulas: 1) For orifice flow Where, Q : discharge through the gate (m3 /s) A : Flow area (m2 ) H = WL – Centre level of orifice (m) 2) For pipe flow fe : loss coefficient for entrance (0.1 ~ 0.5) fb : loss coefficient for bend ={0.131+0.1632(D/R)3.5 } (θ/90)0.5 D : pipe diameter (m) R : radius of curvature (m) θ : bend angle (º) f : loss coefficient for friction = 124.5n2 L/D(4/3) L : length of pipe z Water depth between the Minimum Operational Level (MOL) and the centre level of the penstock inlet is given by the following: Power Canal Head Tank Sand Drain Gate Spillway Trashracks φ Bs h FSWL MOL 30 ~ 50 cm Uniform flow depth at Qdesign Penstock Gate Air Vent Pipe Source: JICA Study Team Figure 2.4.3 Head Tank V > (Qmax) x 20 sec +A x 0.8 5 . 1 84 . 1 H Bs Q ⋅ ⋅ = H g A Q ⋅ ⋅ ⋅ ⋅ = 2 6 . 0 f f f H g A Q b e + + + ⋅ ⋅ ⋅ = 1 2

- 49. -42- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Where, h : depth between MOL and pipe centre (m) φ : diameter of penstock pipe (m) z An air vent pipe is required when the inlet gate is provided on the inlet of the penstock. The diameter of the air vent pipe is given by the following empirical formula: Where, φ : diameter of air vent pipe (m) P : power output (kW) L : length of air vent pipe (m) H : head of penstock (m) z The sectional shapes of head tank should be designed to avoid any abrupt changes that can cause the occurrence of a vortex. z An average slope of head tank is 1/15 ~ 1/50 in order to drain the sediment deposited in the tank through a sand drain gate. Omission of Spillway z The spillway of the head tank can be omitted when the discharge is regulated in the intake and the following conditions are applied: 1) Deflectors are attached for Pelton or Turgo Impulse type turbines. 2) An outlet valve, branched from the penstock pipe, is provided to release the discharge during load rejection. The valve opening is connected with the closure of the guide vane. 3) A dummy load governor, which is applied to mini/micro hydropower schemes smaller than 300 kW, is provided to respond to load rejection. h > φ (φ < 1.0 m) h > φ2 (φ > 1.0 m) 273 . 0 2 ) ( 0068 . 0 H L P = φ

- 50. -43- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 1 2 3 4 5 6 7 8 9 10 11 12 River Discharge Irrigation water Max. turbine discharge with pondage Max. turbine discharge without pondage Required pond capacity Q (m3 /s) Available power Discharge Source: JICA Study Team Figure 2.5.1 Pondage Capacity 2.5 Regulating Pond z A regulating pond is provided for daily peak power generation, of which the location is selected at a flat area to accommodate the required pond capacity, which needs to be enough to meet a power demand, especially during a dry season. z The pondage capacity should be determined to allow supply, with a supplementary discharge during a target operation period of time when the available discharge is insufficient for the power demand, while reserving the available water during the rest of the day. z The peak power operation can be made by monitoring the water level gauge to be equipped in the pondage. Inflow discharges can be estimated by the following equations: z The following is an example of inflow estimate: 600 , 3 ) ( ) ( ⋅ − = ⋅ = ⋅ = out in Q Q dt dH H S dt dH dH dV dt dV ) ( 600 , 3 ) ( H S Q Q dt dH out in ⋅ − = out in Q H S dt dH Q + ⋅ = 600 , 3 ) ( Where, H : Water level in the pond (m) dH/dt : Fluctuation of water level in the pond in one hour (m/hour) Qin : Inflow into the pond (m3 /s) Qout : Turbine discharge (m3 /s) S(H) : Surface area of the pond at water level of H (m2 ), which is expressed as (aH2 + bH + c)

- 51. -44- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Nomogram for Inflow Estimation 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 -1.0 -0.8 -0.6 -0.4 -0.2 0.0 0.2 0.4 0.6 2-unit operation 1-unit operation dH/hour : fluctuation of water level in 1 hour Average water level : EL.687.000 Qin (m3 /s) dH/hour (m/hour) z The opening degree of the guide-vanes are to be kept constant during the time on peak. Sand Flushing through the ‘Saxophone’ Suction Head z To utilise a head between the pondage and outlet without using other energy such as electricity or diesel. z Sand flushing can be made under power generation, therefore it is not necessary to stop power generation during a sand flushing operation. z There is a experimental data reported that about 10% of the sand volume density can be flushed. However, it is noted that such a flushing percentage is subject to the nature of sediment deposit. z It is reported that this metod is suitable to flush sediment in a pondage or a de-silting basin where sediment is light and particle size small. Consequently, simple and small-scale flushing facilities are needed for such a pondage or a de-silting basin. 1) Power operation with 2-unit (320 kW, Qout=0.65 m3 /s) 2) 2) Reading of water level in the pond by pressure gauge 3) 3) When fluctuation of water level during 1.0 hour is -0.35m , and average water level is 687.000m under 2-unit operation Qin = -0.35 x (687.000 - 661.000) x (687.000 - 586.000) / 3,600 + 0.65 = 0.395 m3 /s Source: JICA Study Team Figure 2.5.2 Inflow Estimation

- 52. -45- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Example: z Pipe φ = 15 cm, L = 20 m f f N f H g V b e + ⋅ + + ⋅ = 1 2 fe = 1.00 (inlet loss), N·fb = 0.40 (bend loss), f = fr(L/D)=4.5 (friction loss) fr = 12.7g・n2 ・D1/3 = 0.03373 and n = 0.012 (roughness coefficient) When H (head) = 1.5 m, V (velocity) = 2.06 m/s, z Pipe φ = 15 cm, L = 20 m, H = 1.5 m, V = 2.06 m/s Q = 0.036 m3 /s (= 2.19 m3 /min = 131 m3 /hr) : discharge flushed Sand= 131 m3 /hr x 10%*1 = 13.1 m3 /hr (= 315 m3 /day*2 ): sand volume flushed Note: *1 : In reference to the experimental data as a calculation example. *2 : In application of 24 hours as a calculation example for the daily working hours of the sand flushing device. Head Open Slots Sediments Source: D.K.Lysne, New Norwegian Institute of Technology Figure 2.5.3 'Saxophone' Sand Flushing

- 53. -46- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 Table 2.5.1 Sand Flushing Capacity of 'Saxophone' Suction Head Source: JICA Study Team Dia. L H V Q Q Sand Sand (m) (m) (m) (m/s) (m3 /s) (m3 /hr) (m3 /hr) (m3 /day) 0.1 10 1.5 2.17 0.017 61 6.1 146 0.1 10 3 3.06 0.024 86 8.6 206 0.1 20 1.5 1.7 0.013 47 4.7 113 0.1 20 3 2.41 0.019 68 6.8 163 0.1 30 1.5 1.45 0.011 40 4 96 0.1 30 3 2.05 0.016 58 5.8 139 0.1 40 1.5 1.28 0.01 36 3.6 86 0.1 40 3 1.82 0.014 50 5 120 0.1 50 1.5 1.16 0.009 32 3.2 77 0.1 50 3 1.65 0.013 47 4.7 113 0.1 60 1.5 1.07 0.008 29 2.9 70 0.1 60 3 1.52 0.012 43 4.3 103 0.15 10 1.5 2.51 0.044 158 15.8 379 0.15 10 3 3.56 0.063 227 22.7 545 0.15 20 1.5 2.06 0.036 130 13 312 0.15 20 3 2.92 0.052 187 18.7 449 0.15 30 1.5 1.79 0.032 115 11.5 276 0.15 30 3 2.54 0.045 162 16.2 389 0.15 40 1.5 1.61 0.028 101 10.1 242 0.15 40 3 2.27 0.04 144 14.4 346 0.15 50 1.5 1.47 0.026 94 9.4 226 0.15 50 3 2.08 0.037 133 13.3 319 0.15 60 1.5 1.36 0.024 86 8.6 206 0.15 60 3 1.92 0.034 122 12.2 293

- 54. -47- The Study on Introduction of Renewable Energies in Rural Areas in MYANMAR Nippon Koei / IEEJ Volume 4 Manuals Part 2 2.6 Penstock z Alignment of the penstock should be designed to be located below the minimum hydraulic grade line during the load rejection to avoid negative pressure. Penstock Powerhouse TWL Static Head Anchor Block Spillway HeadTank SandDrain Gate Trashracks FSWL MOL Hydraulic Grade Lines Max. Pressure Rise Min. Pressure Drawdown > Penstock Elevation 50 ~ 100 m max. Max. velocity 2.5 m/s (inlet) ~ 5.0 m/s (outlet) 55º max. Source: JICA Study Team Figure 2.6.1 Penstock Negtive pressure occurs Hydraulic Grade Line