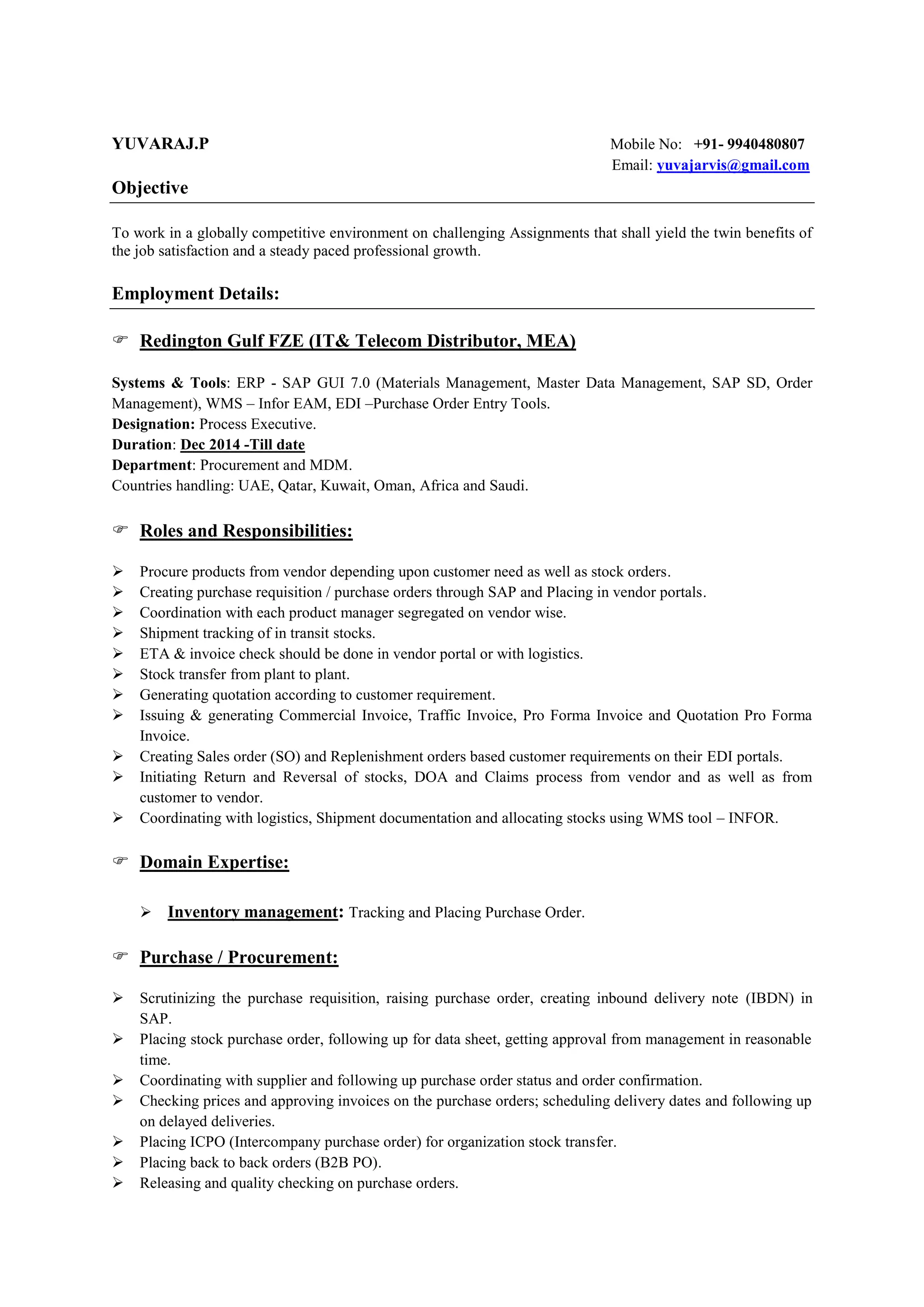

Yuvaraj P. is an experienced professional seeking opportunities in a competitive environment, currently working as a Process Executive at Redington Gulf FZE since December 2014. He specializes in procurement, inventory management, and logistics operations, using ERP systems like SAP and WMS tools. He holds an MBA in Logistics and Supply Chain Management and has received recognition for his performance and training in stores management and shipping.