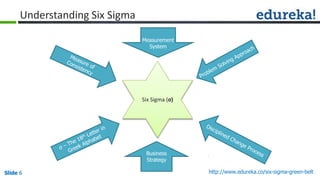

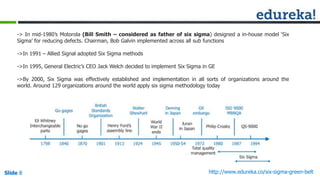

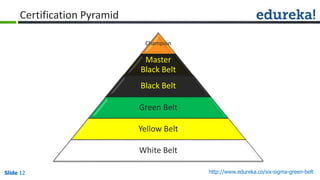

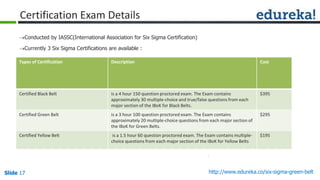

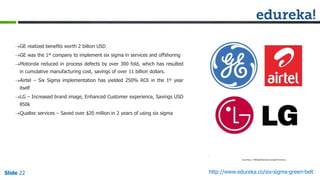

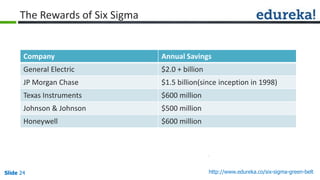

The document provides an overview of Six Sigma methodology including its origins at Motorola in the 1980s, how it works to reduce defects and improve processes, and the various certification levels from Yellow Belt to Black Belt to Champion. It also outlines benefits companies have realized from Six Sigma implementation including billions in savings annually for companies like General Electric, Johnson & Johnson, and Honeywell.