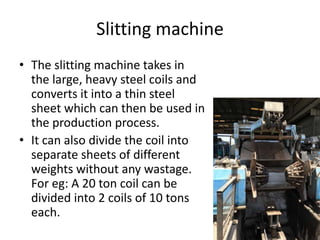

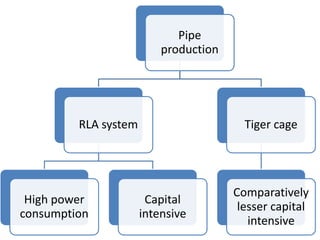

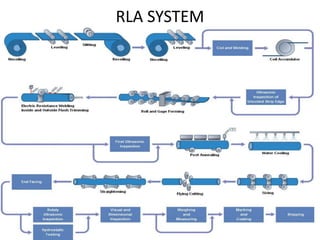

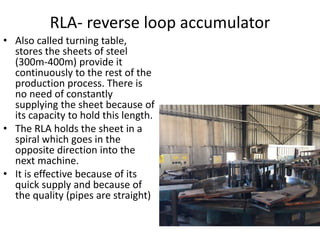

The document describes the production process of steel pipes at Global Steel Industries FZCO. It currently uses the RLA system which involves multiple machines working in sequence. The summary suggests switching to the Tiger Cage system which combines tasks into one machine, reducing capital and operating costs significantly while using less space. While production capacity is lower, the Tiger Cage is more suitable for periods of lower demand due to its much lower power consumption.