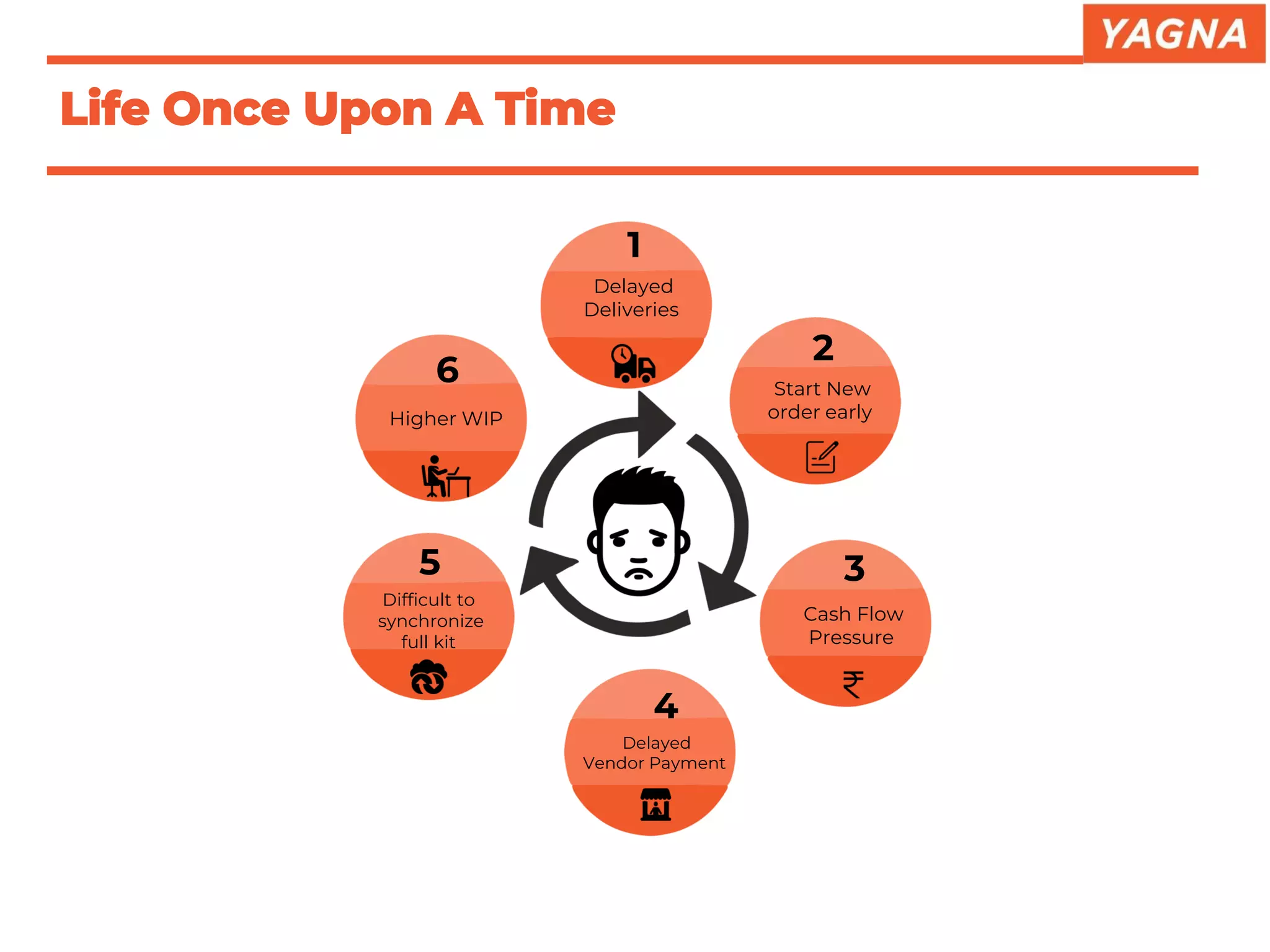

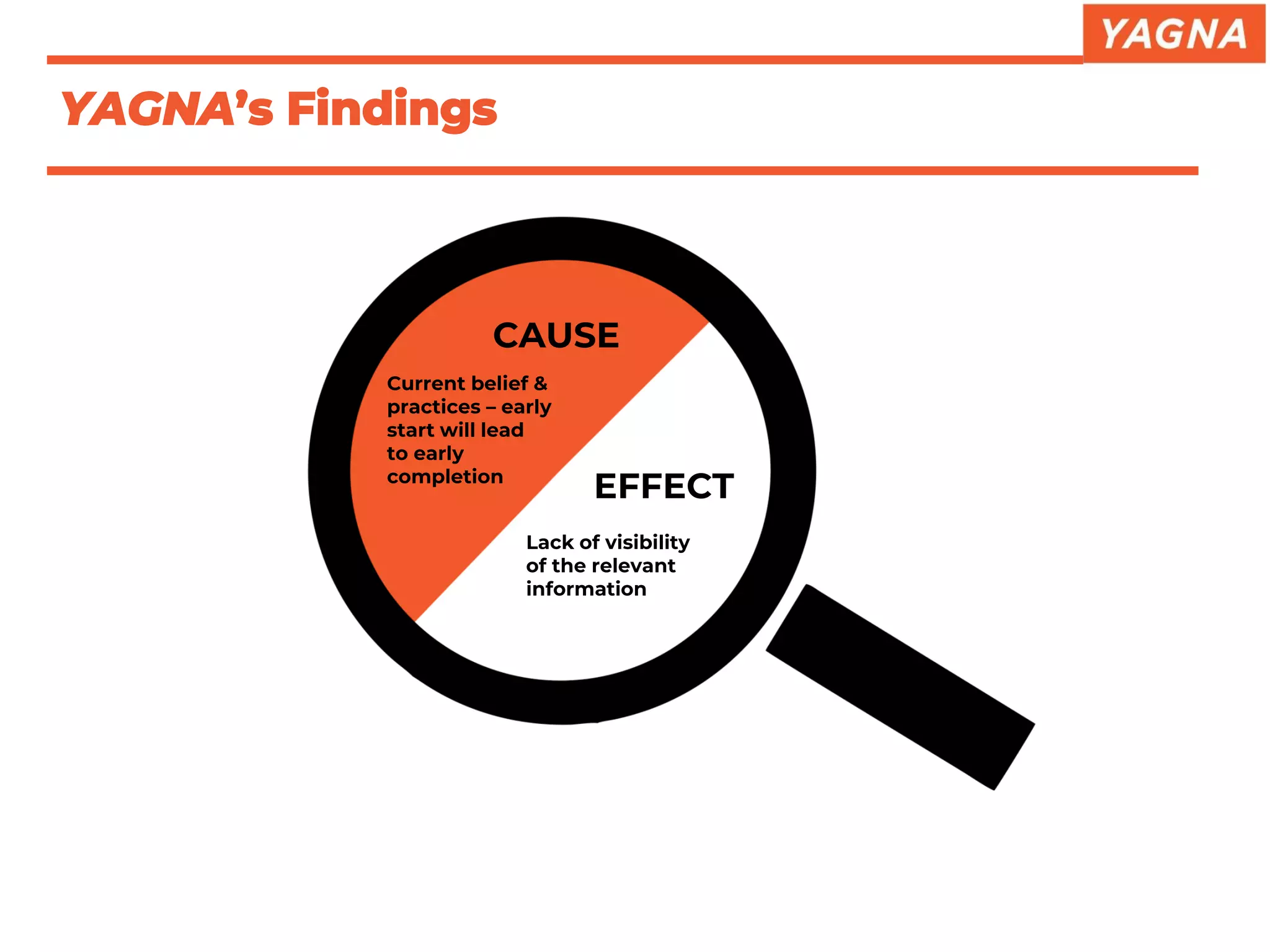

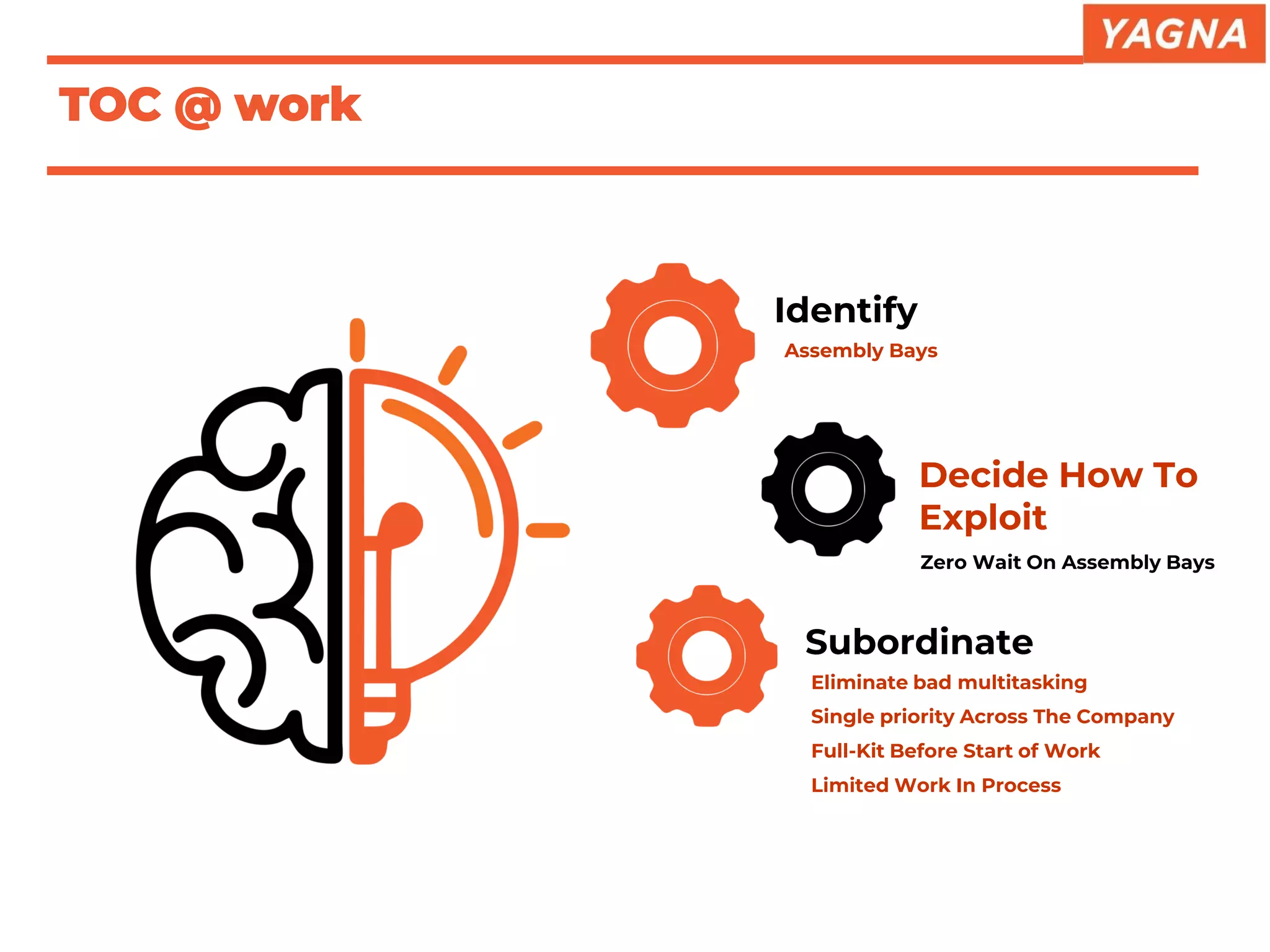

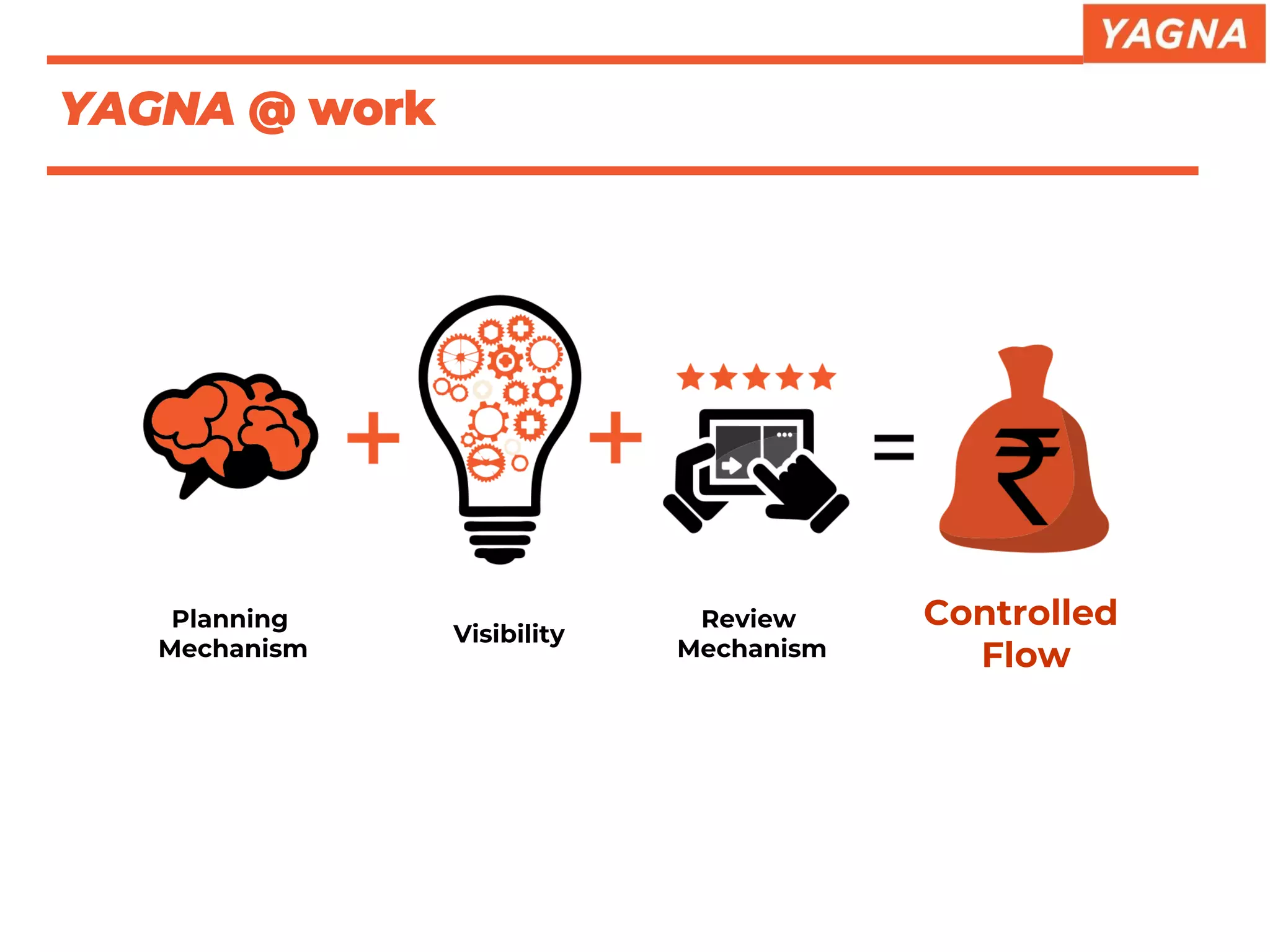

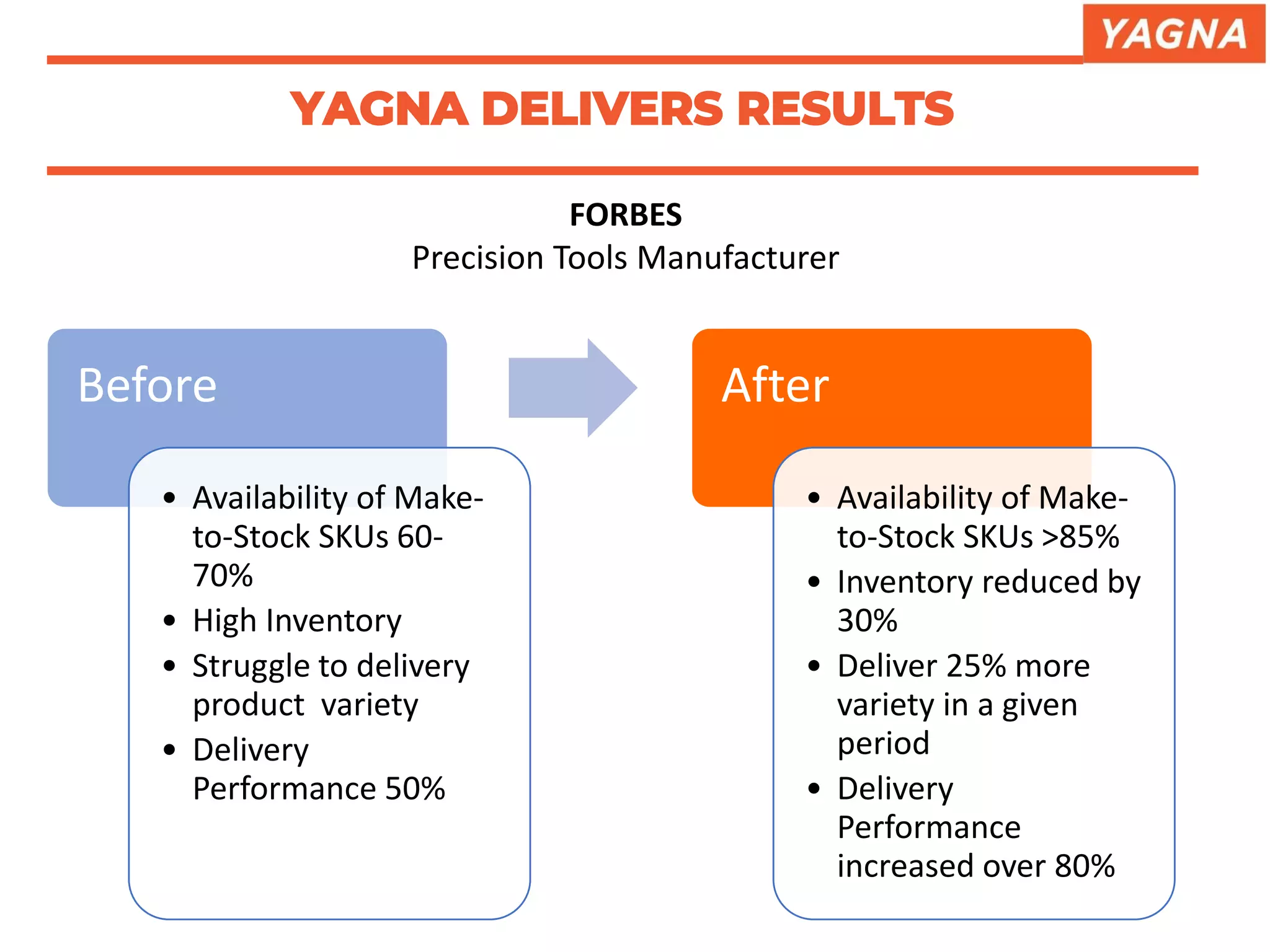

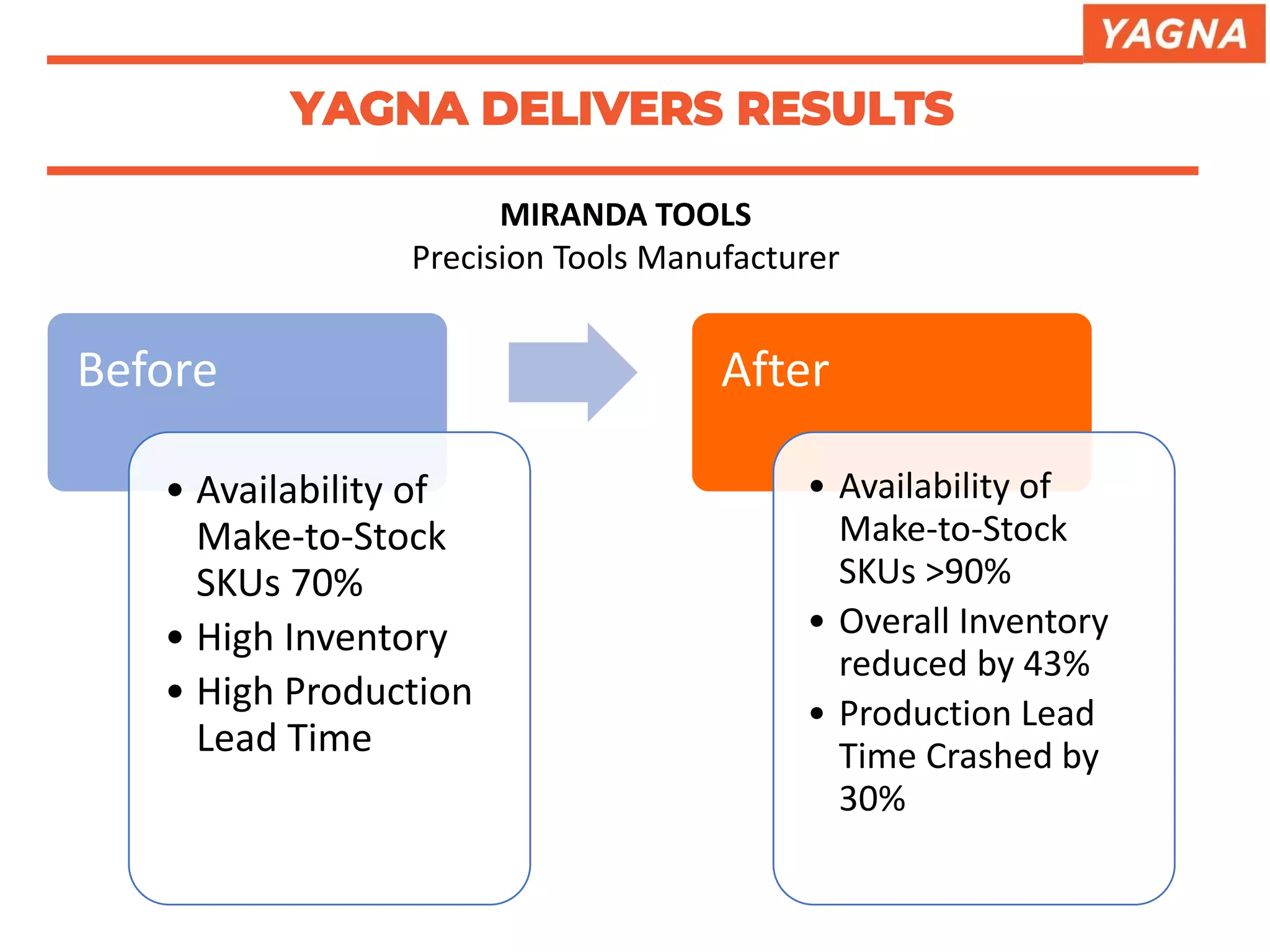

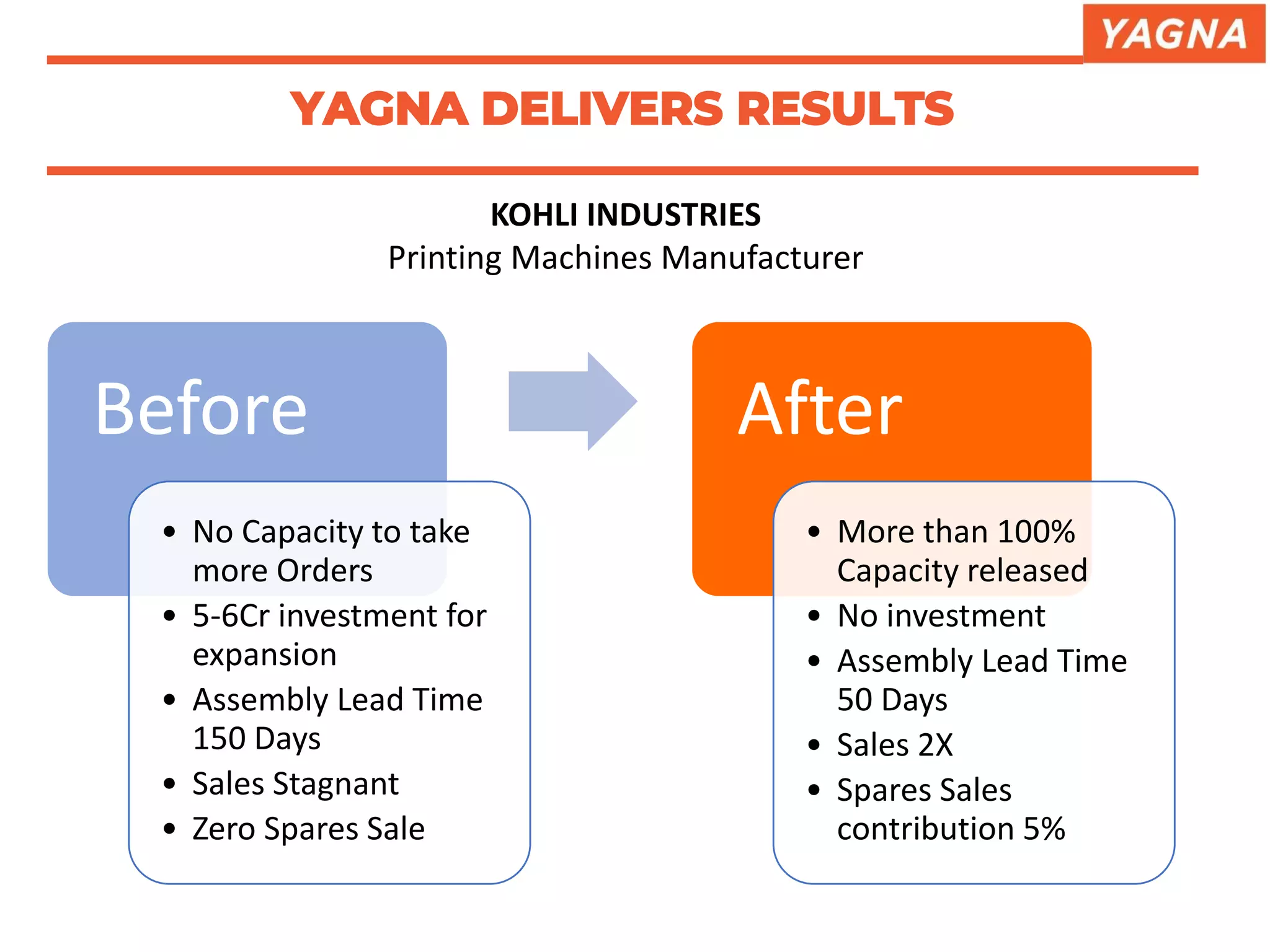

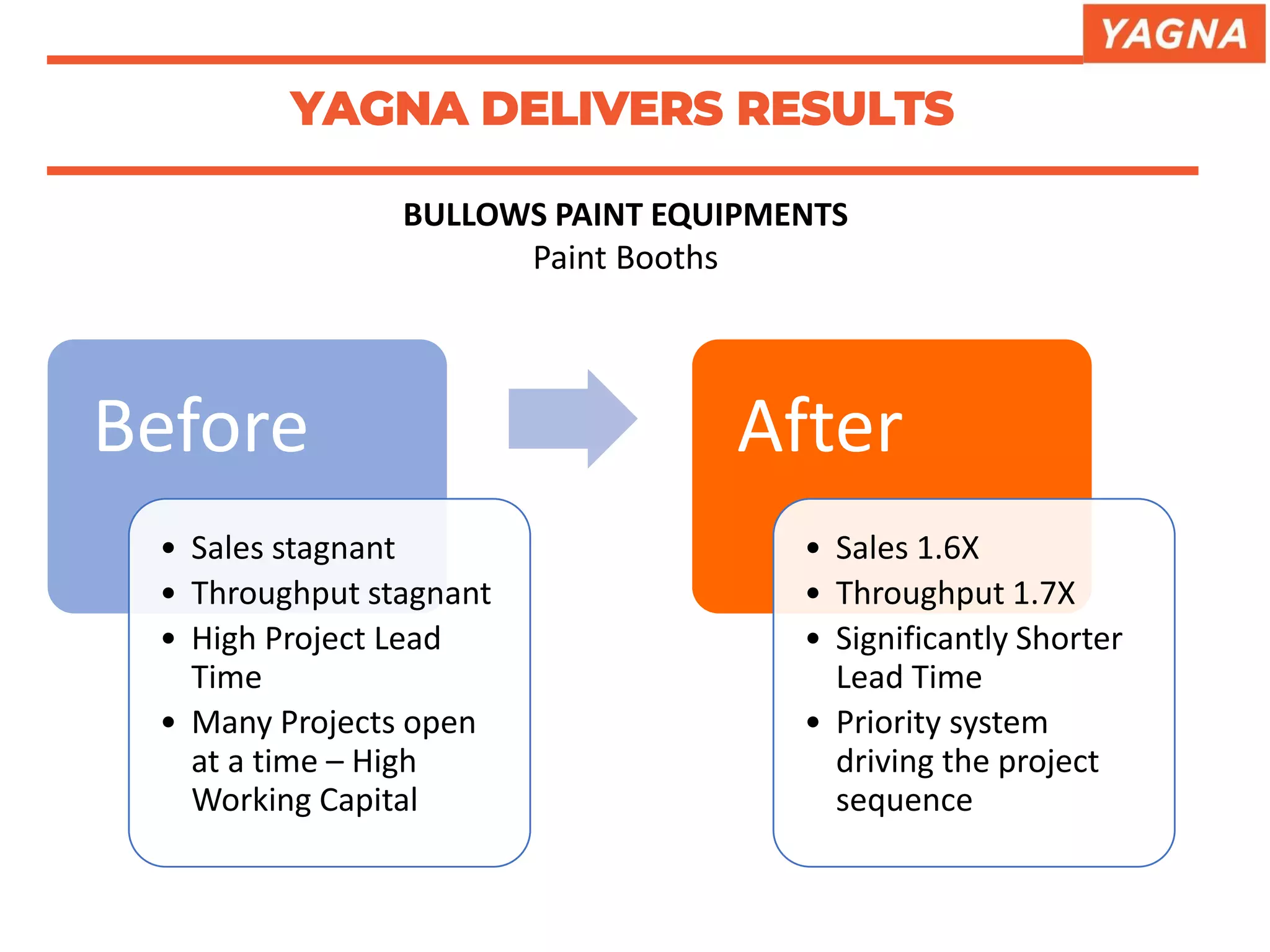

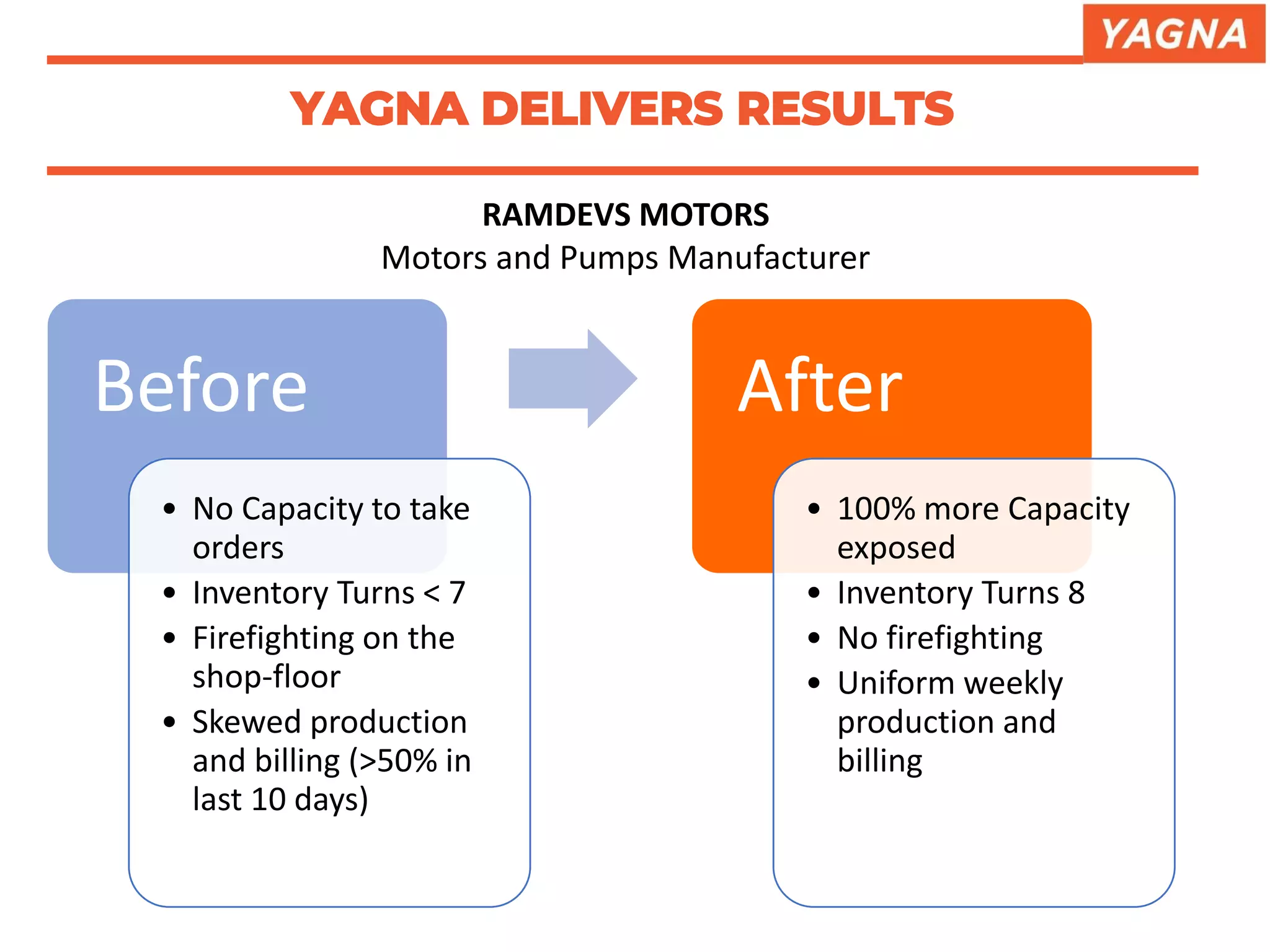

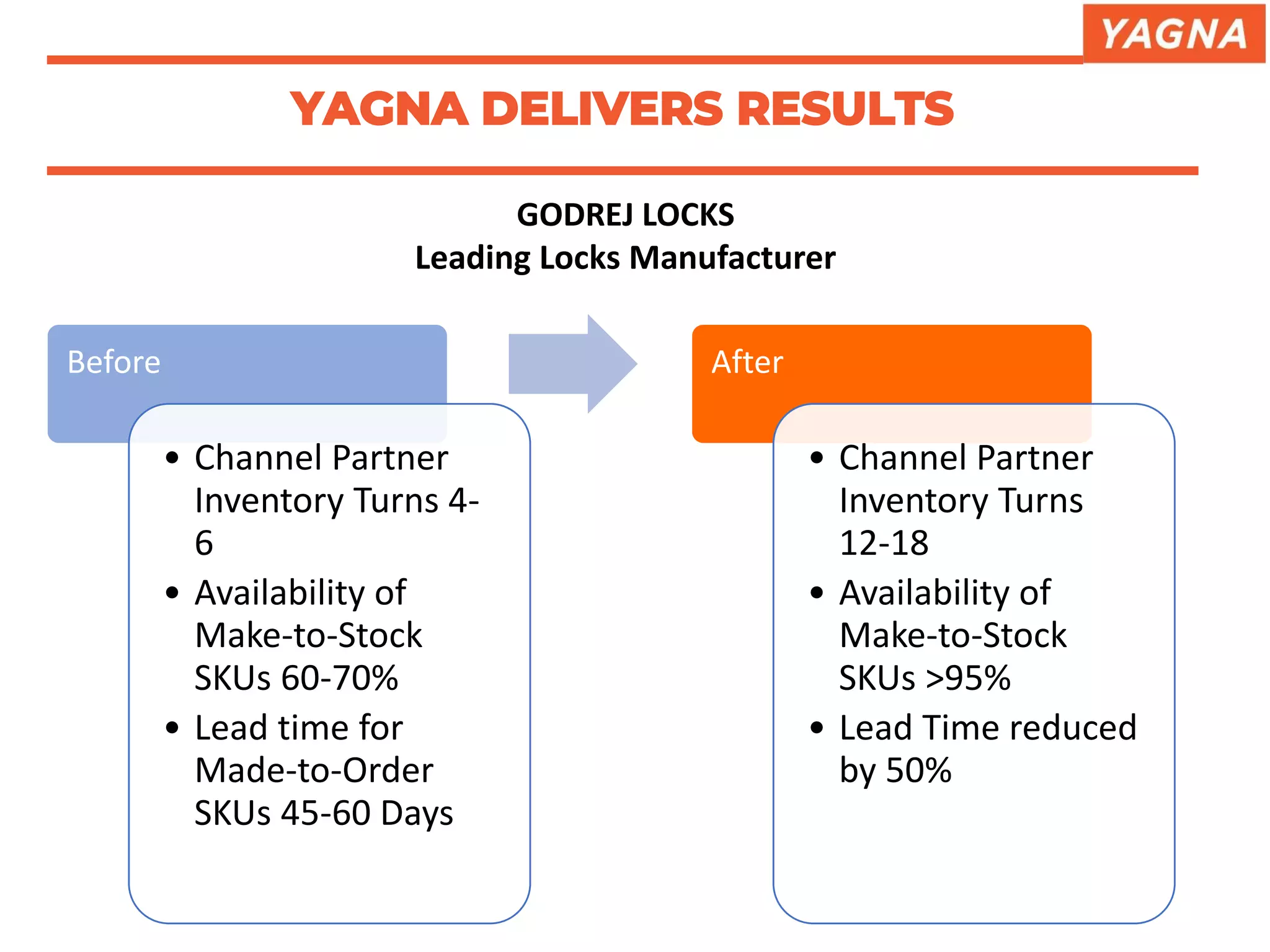

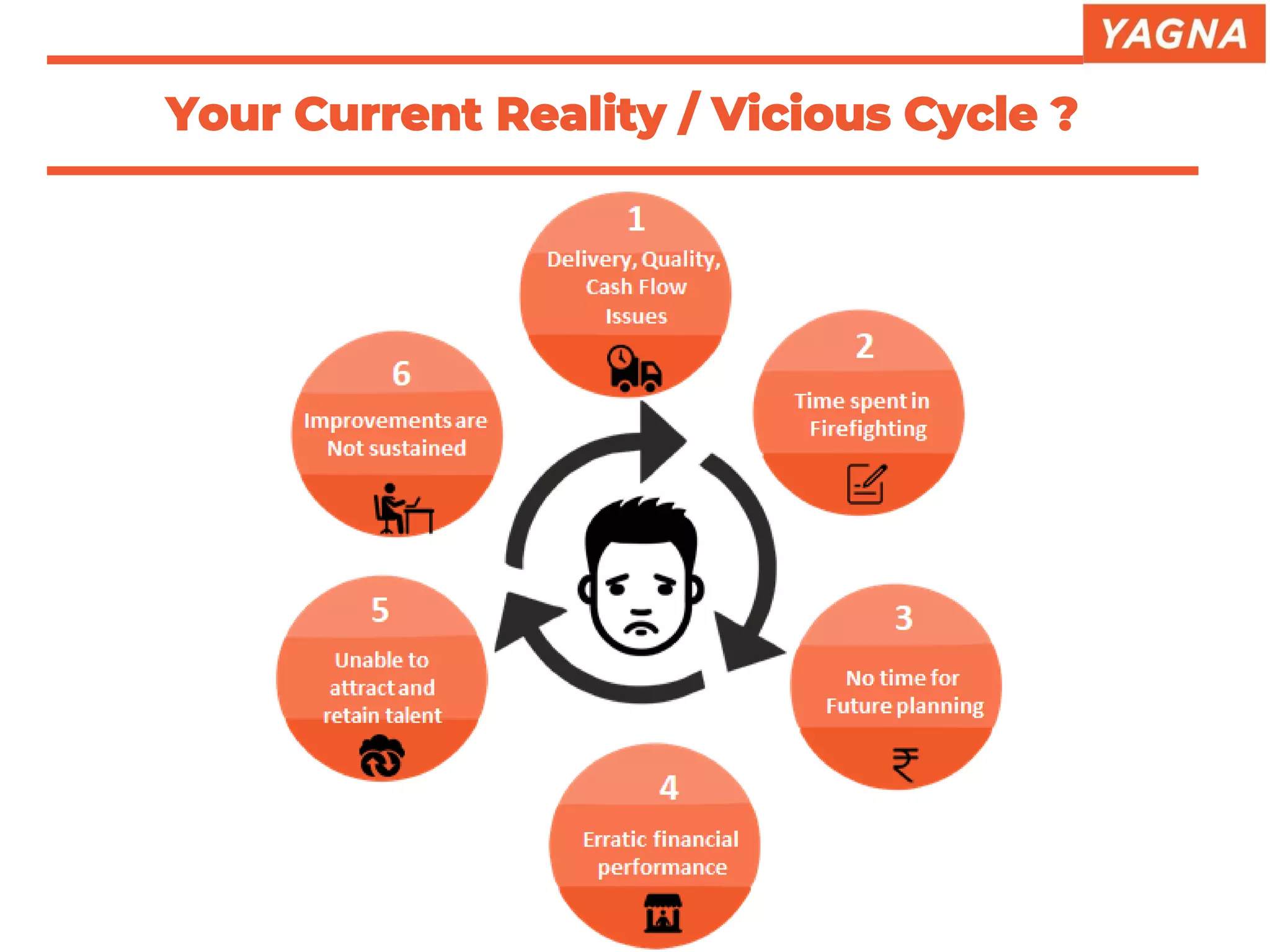

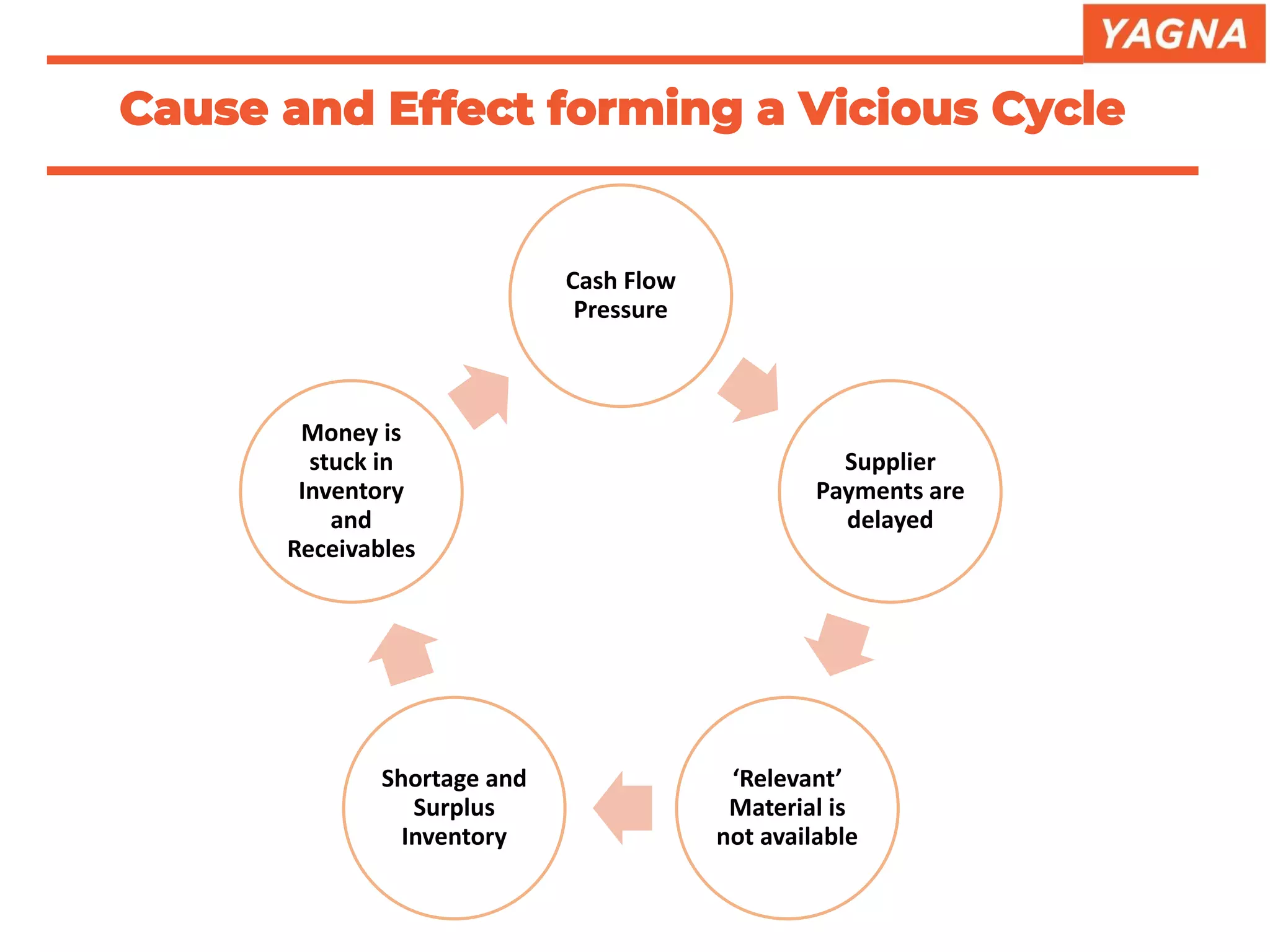

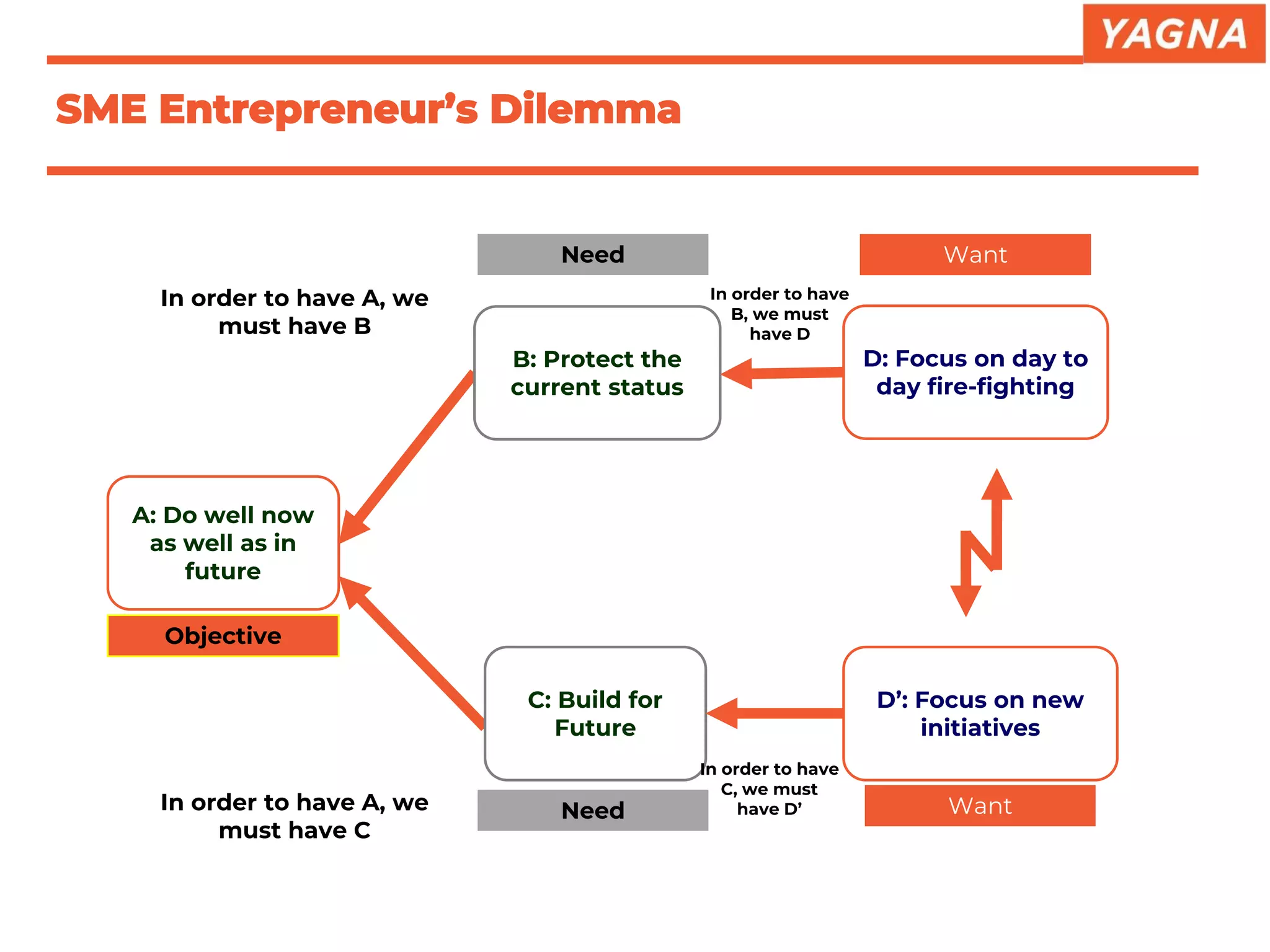

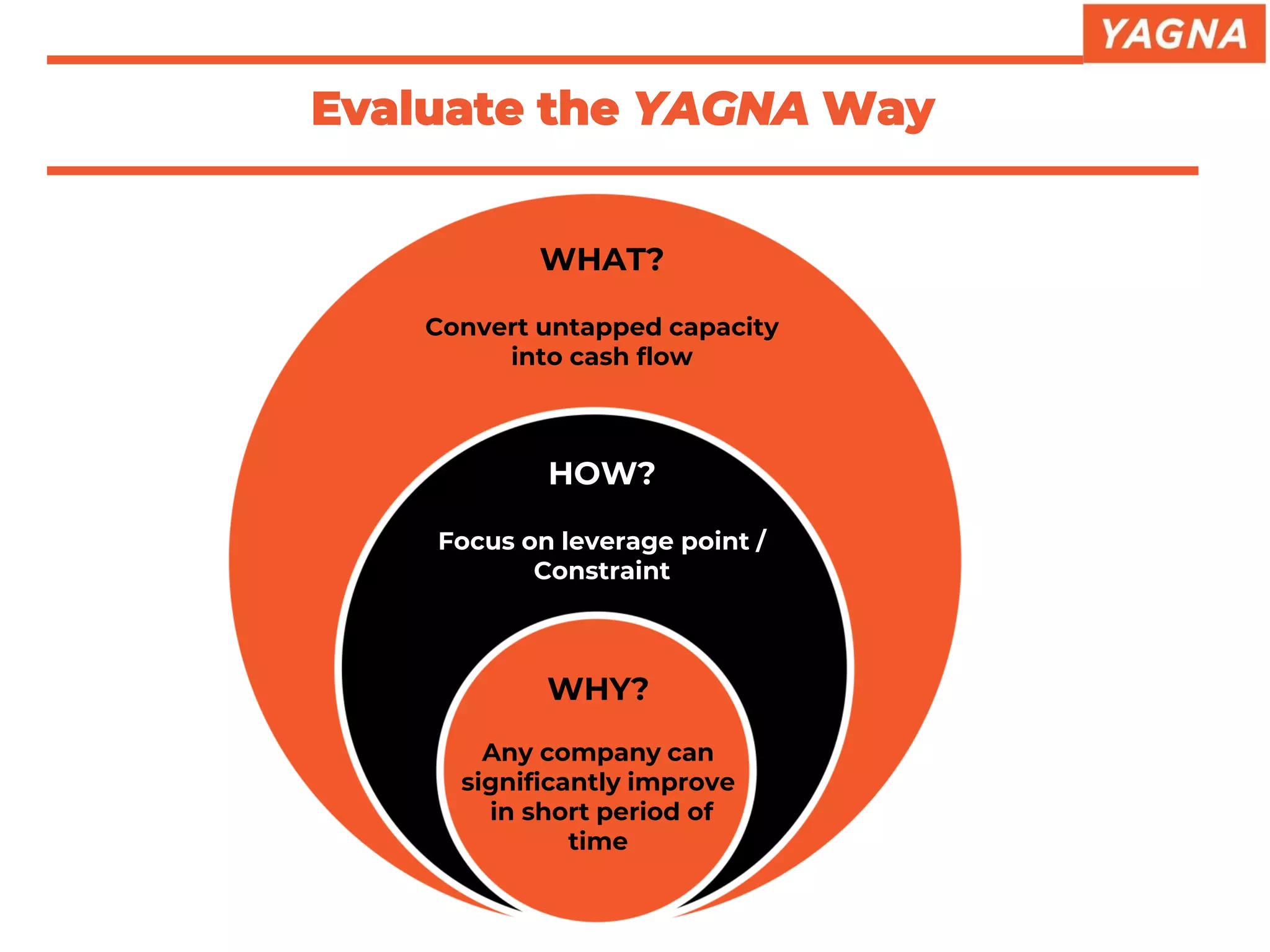

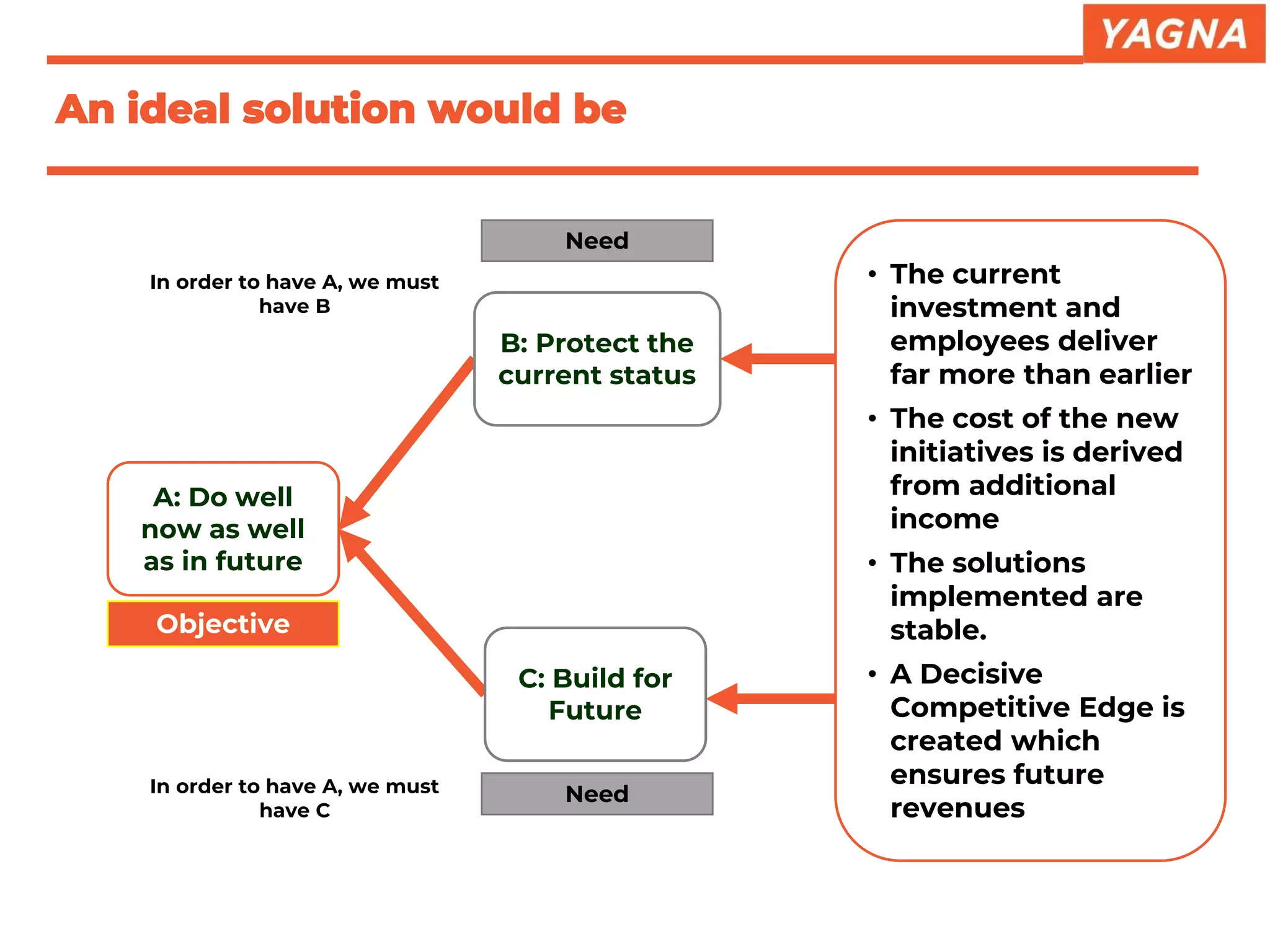

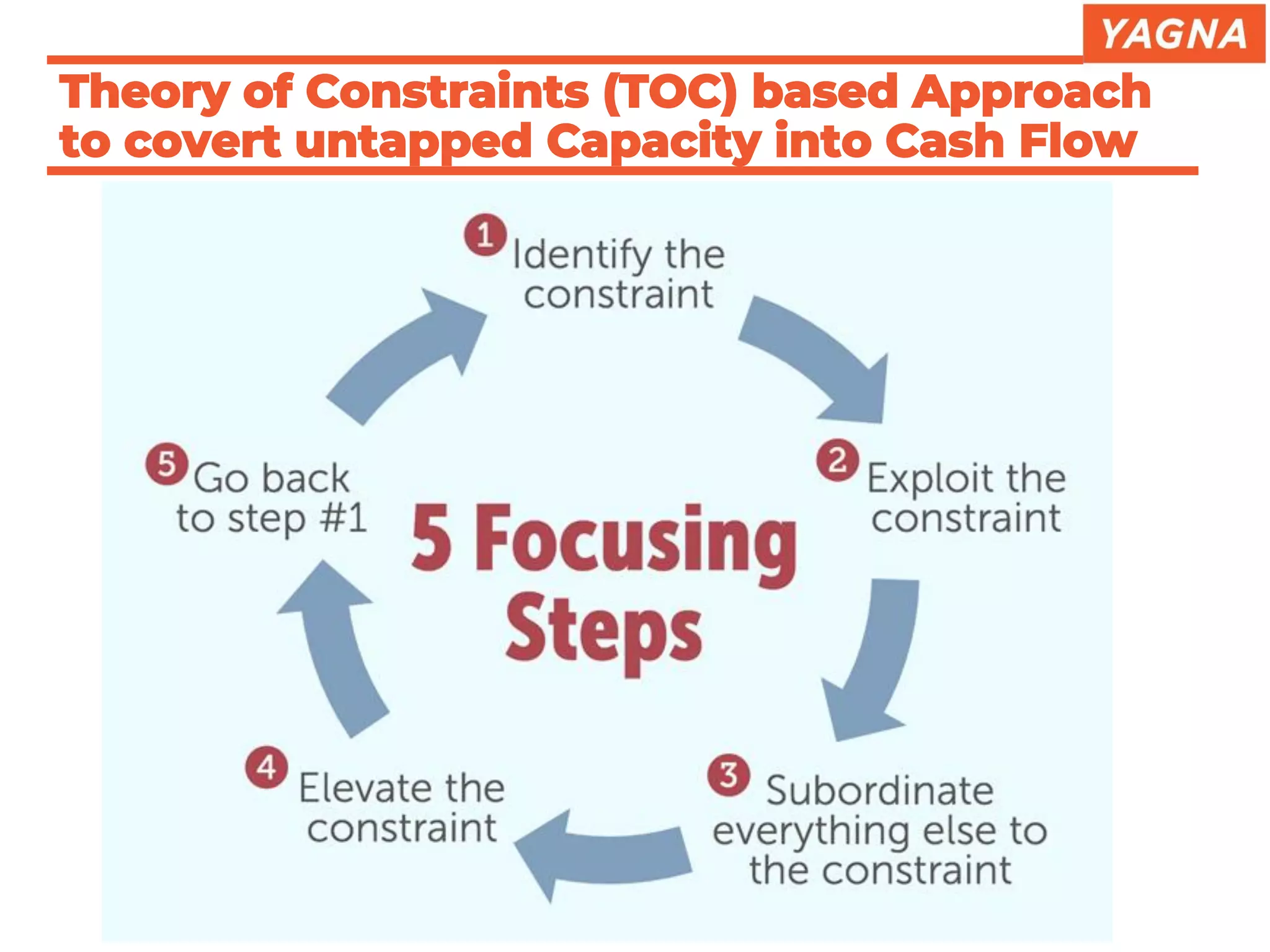

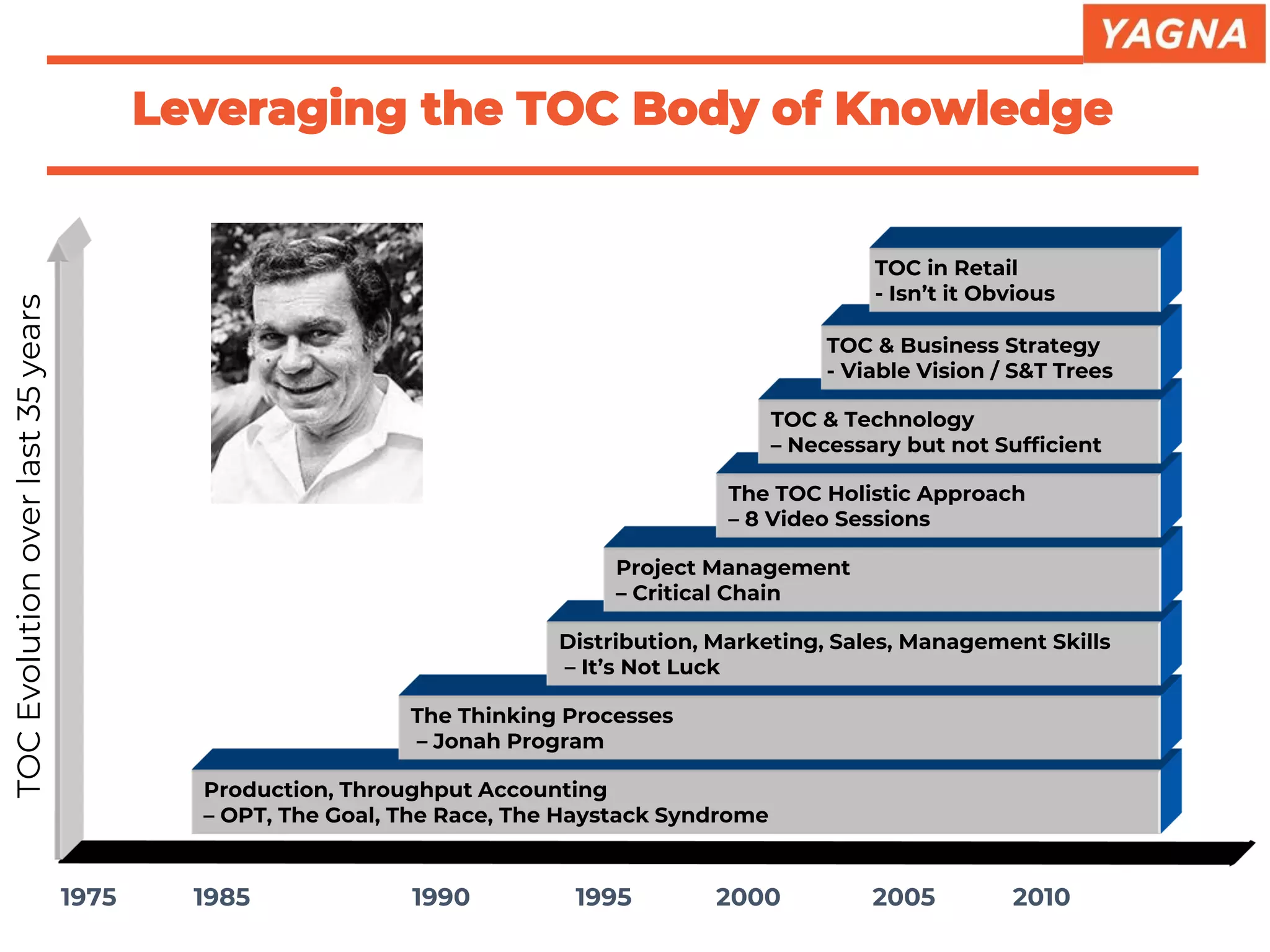

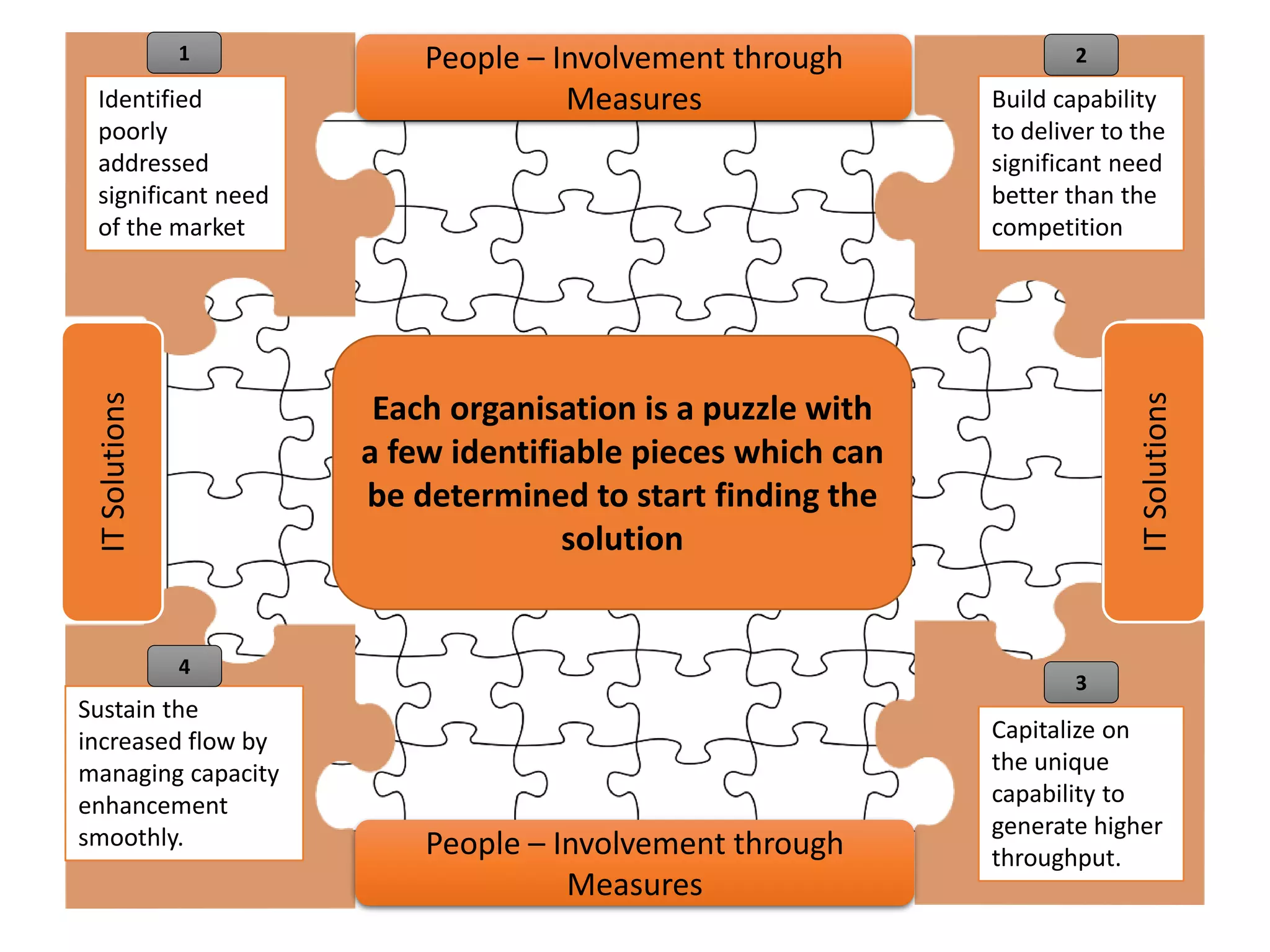

The document discusses common problems faced by SMEs such as low capacity, poor profits and cash flow, delayed customer deliveries, long lead times, material shortages, and high inventory. It presents a vicious cycle diagram to illustrate the interconnected causes and effects. The document then evaluates how the Theory of Constraints (TOC) approach can help convert untapped capacity into cash flow in a short period of time without additional investment by focusing on constraints. Case studies are presented showing how YAGNA has helped various clients significantly improve key metrics like throughput, inventory turns, lead times, and on-time delivery performance within months.

![▪ Imran has an Industry experience of more than 20 years. He worked at

various leadership roles in Industries. Strategy planning, Finance,

Collaboration, JV,

Operations are his stronghold.

▪ He is a strong supporter of Theory of Constraints & other best practices.

Before venturing into consulting he transformed his organisation as

COO into a benchmark business model. Developed business acquiring

many customers in India & Globally & built high performance teams.

▪ Imran is a Mechanical Engineer, Certified Lean Six Sigma Black Belt,

Certified Theory of Constraints [TOC] Practitioner, QMS Auditor & a

Senior Member of American Society for Quality. He has been sharing &

gaining knowledge & experiences through various forums at ACMA,

IIMM, CII & others.

▪ Imran, believes that every situation can be challenged. Win-Win

attitude, Speed & Quality of decision is key. Believes in designing &

working on Process measures to achieve Result measures.

Imran Sheikh](https://image.slidesharecdn.com/yagnaoverviewmay2020-200925091127/75/Yagna-overview-may-2020-22-2048.jpg)