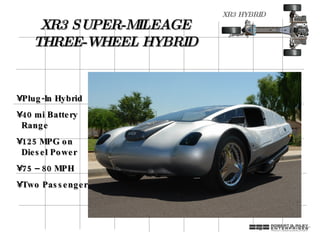

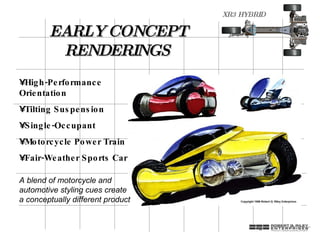

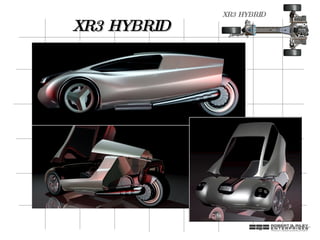

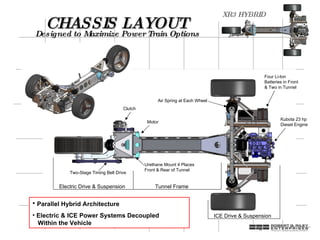

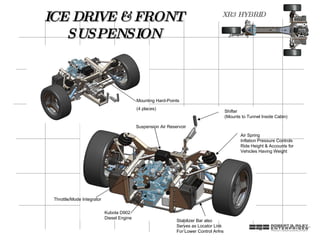

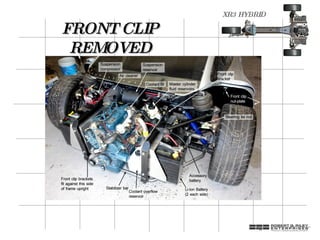

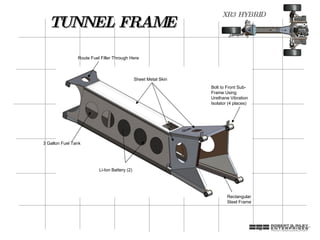

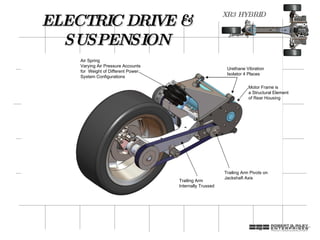

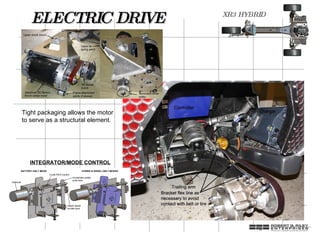

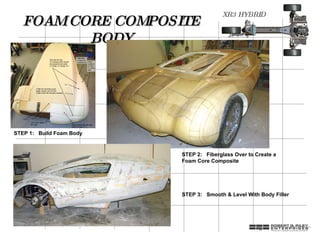

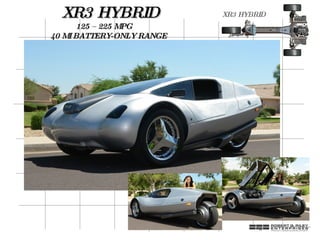

The xr3 is a super-mileage three-wheel hybrid vehicle featuring a 40-mile battery range and an impressive fuel efficiency of 125 mpg on diesel power. It combines elements from both motorcycles and cars, utilizing a parallel hybrid architecture with a Kubota diesel engine and multiple lithium-ion batteries. The design prioritizes high performance and unique styling, with innovations like tilting suspension and adjustable air springs for optimal ride height.