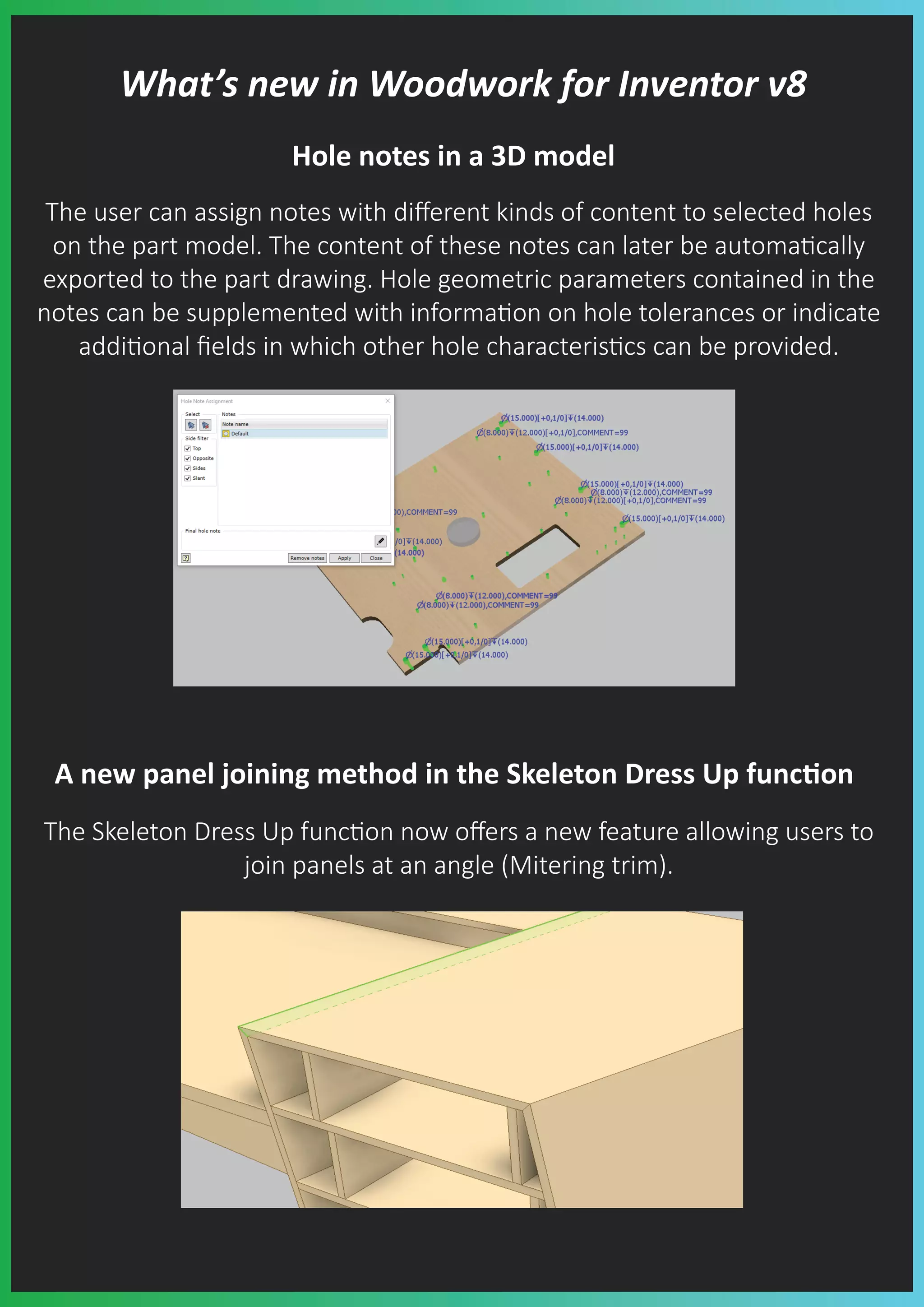

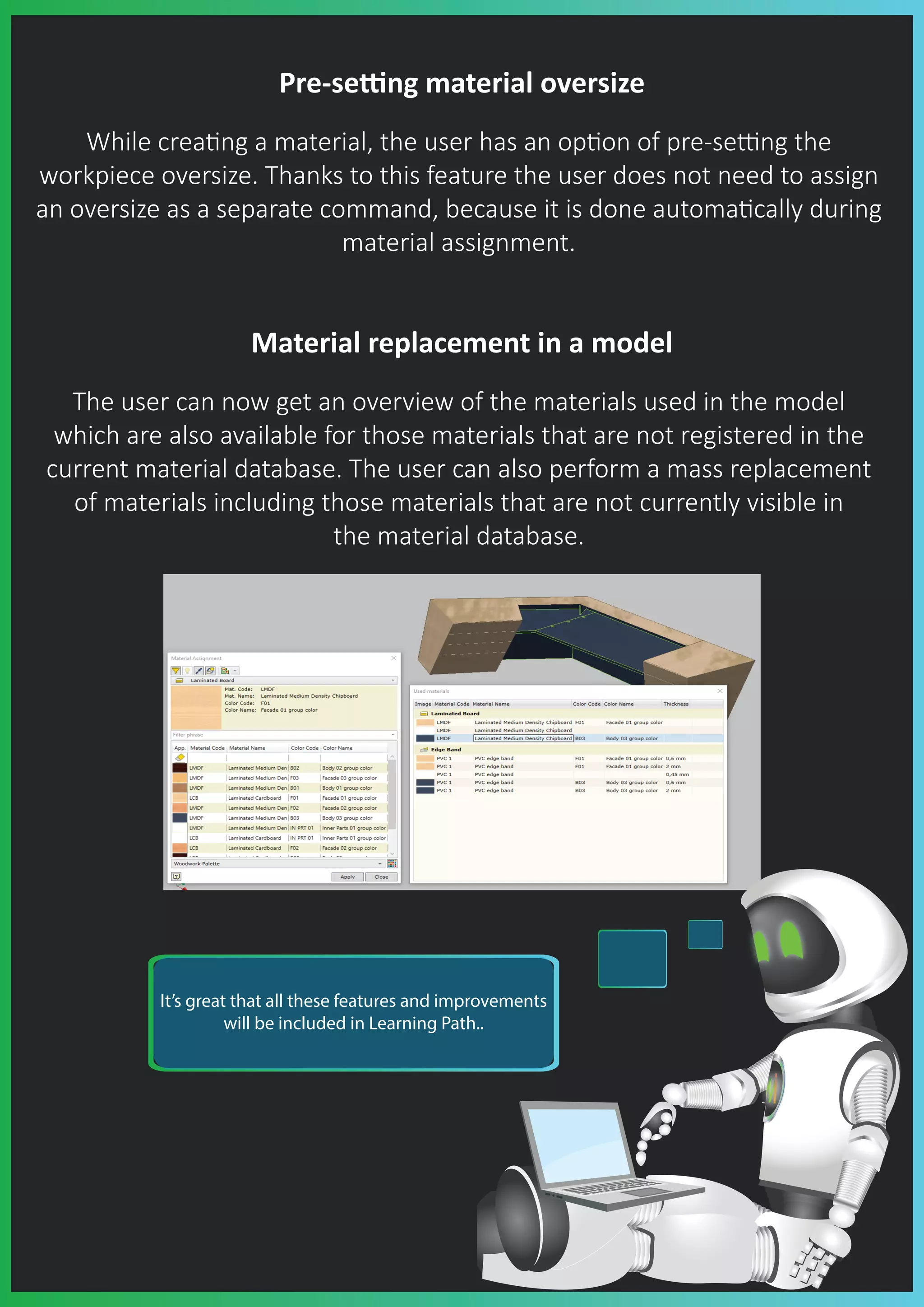

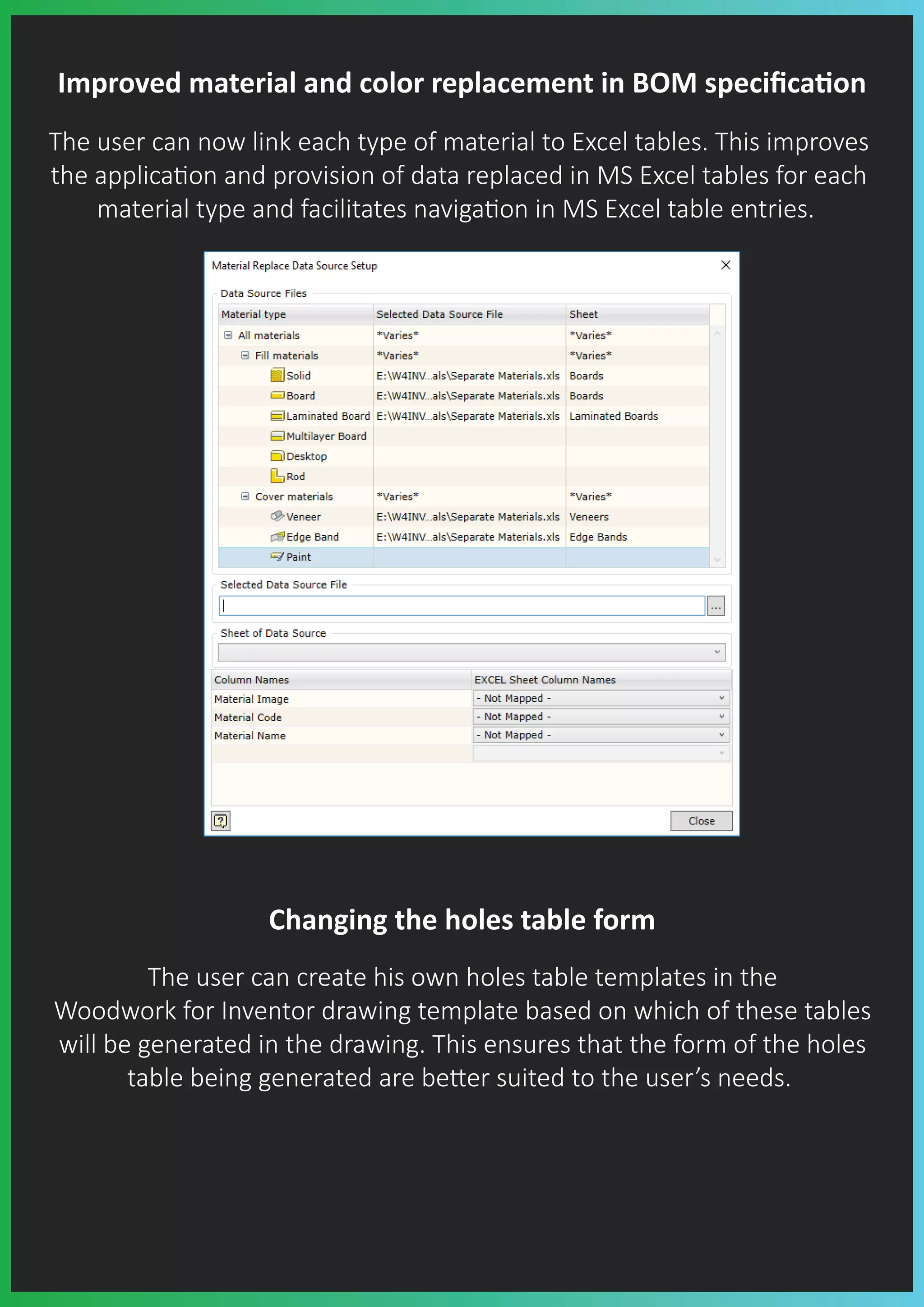

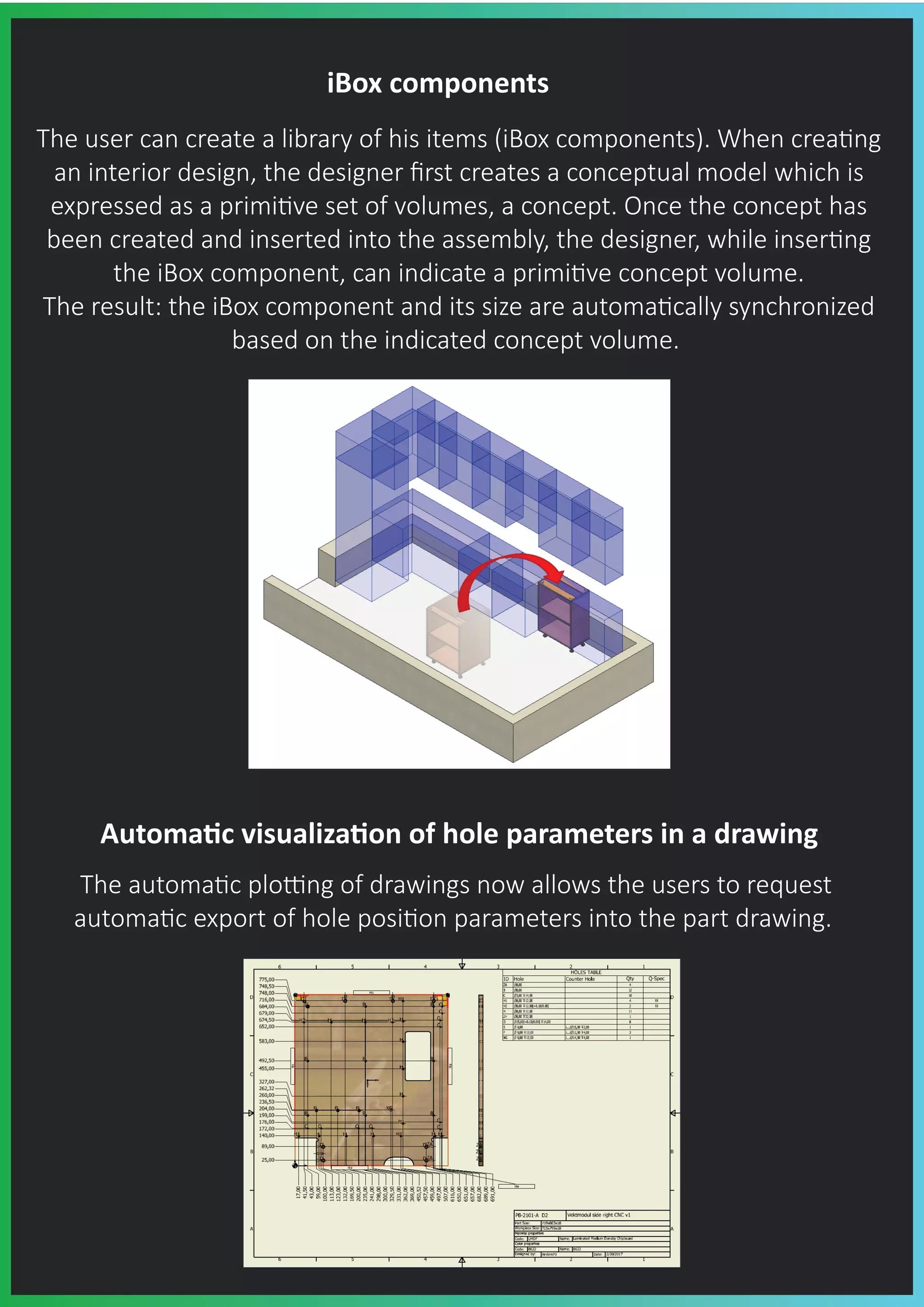

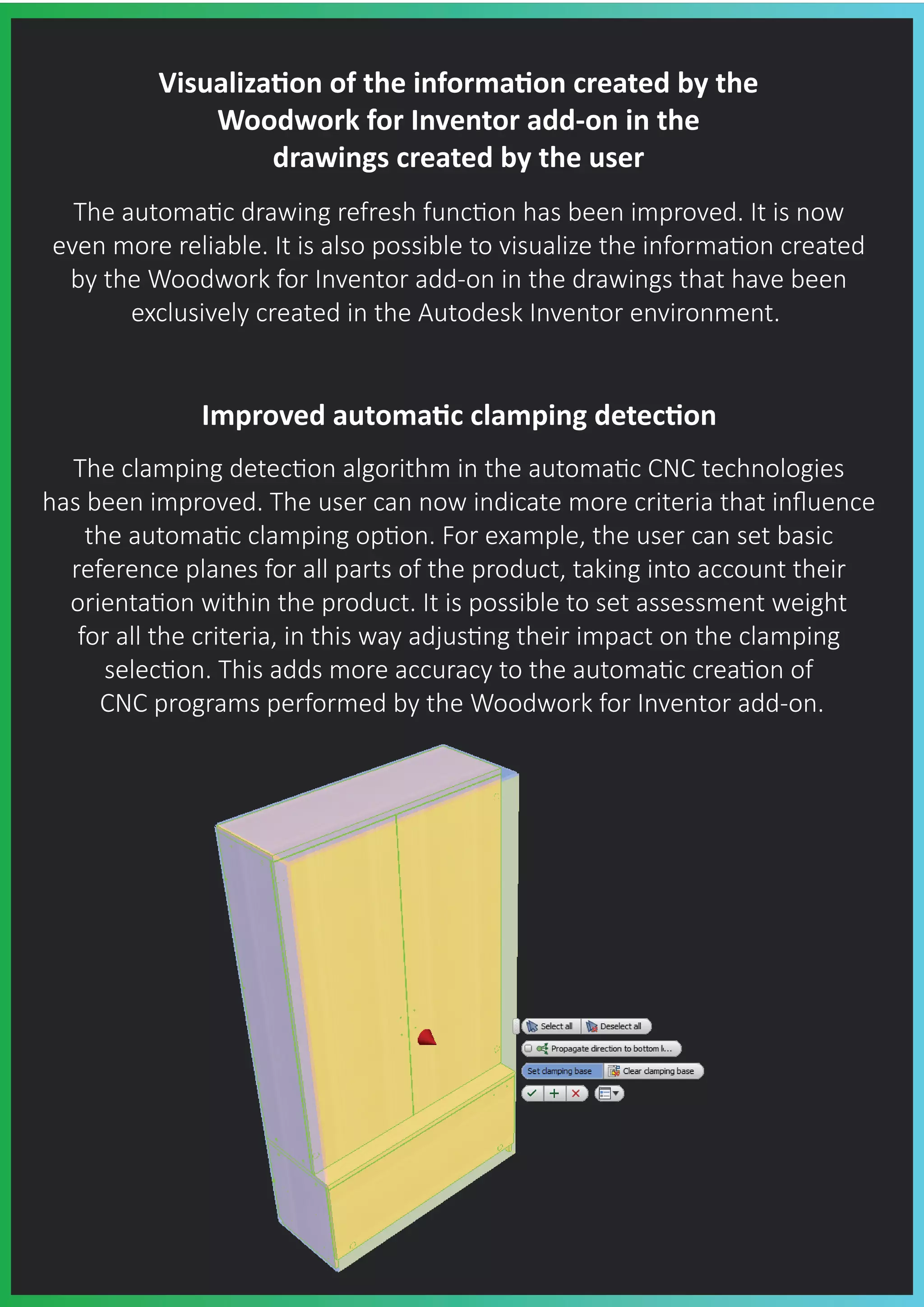

The document outlines new features in Woodwork for Inventor V8, including the ability to assign notes to holes, a new panel joining method, and pre-setting material oversize during material assignment. It also introduces improved material replacement options, custom holes table templates, and the creation of iBox components that sync with conceptual models. Additional enhancements include automatic visualization of hole parameters in drawings and improved automatic clamping detection for CNC technologies.