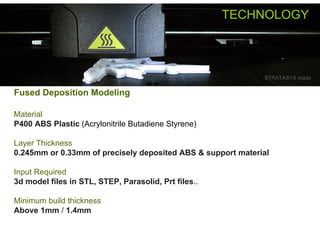

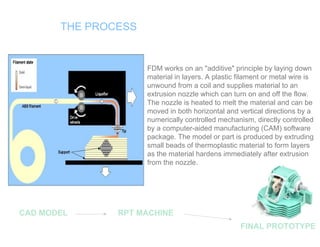

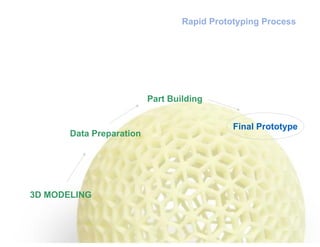

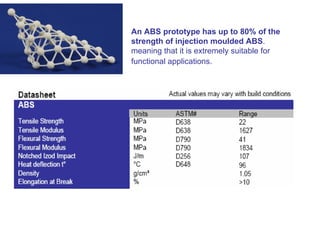

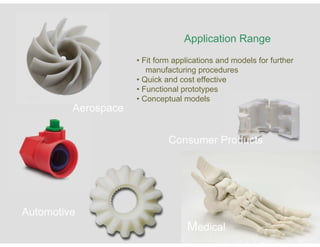

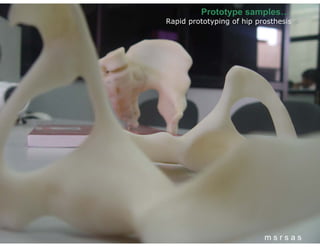

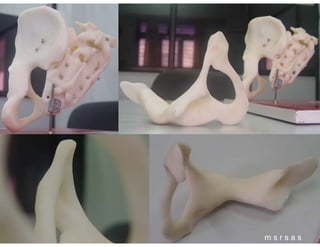

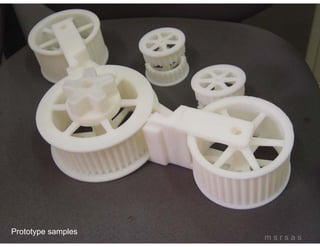

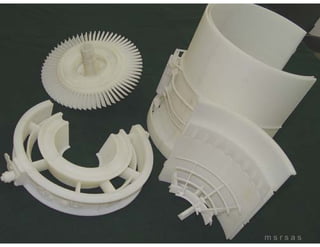

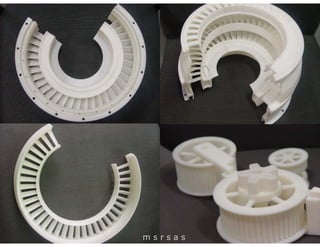

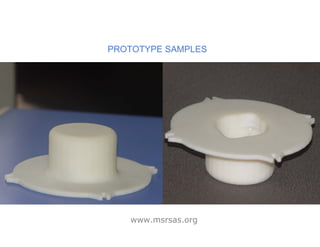

M. S. Ramaiah School of Advanced Studies is a postgraduate engineering and management institute that provides rapid prototyping solutions through its SAS TechnoSolutions Centre. SAS TechnoSolutions uses fused deposition modeling to create prototypes from ABS plastic in layers as thin as 0.245mm. It offers prototyping services for products in industries like aerospace, consumer products, automotive, and medical. Some example prototypes produced include hip prostheses, engine parts, and electronics components. SAS TechnoSolutions clients include DRDO laboratories and new product development organizations.