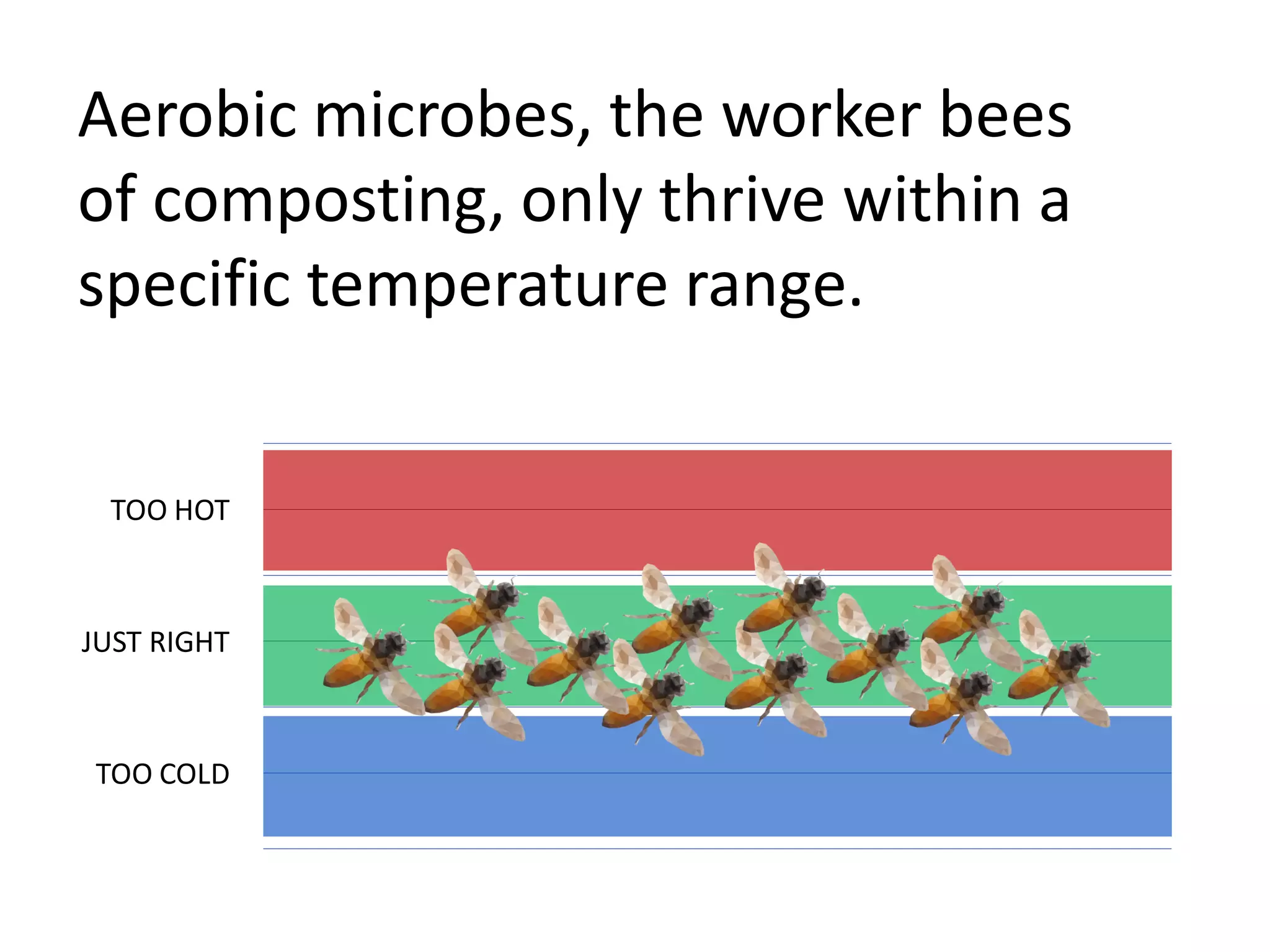

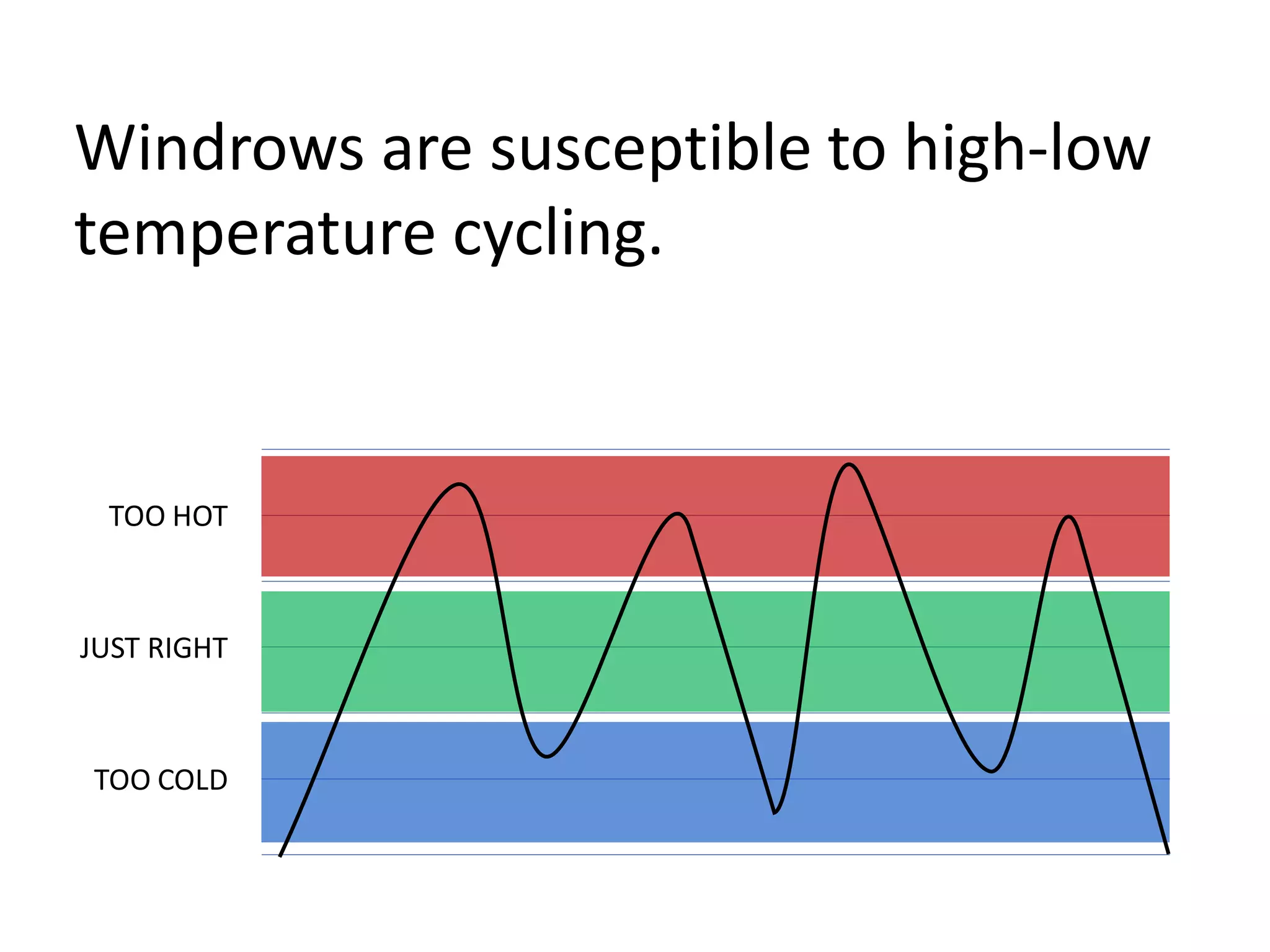

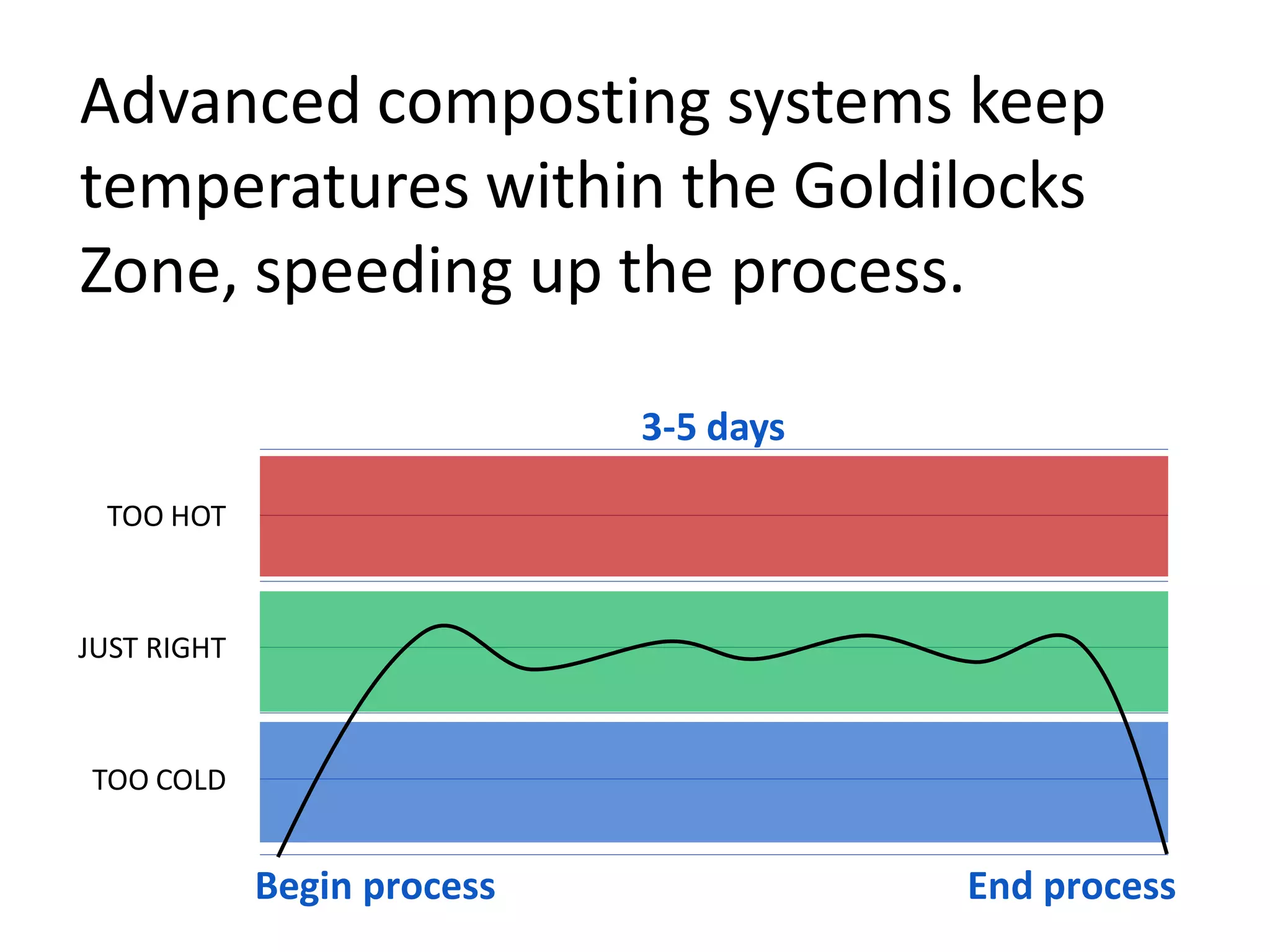

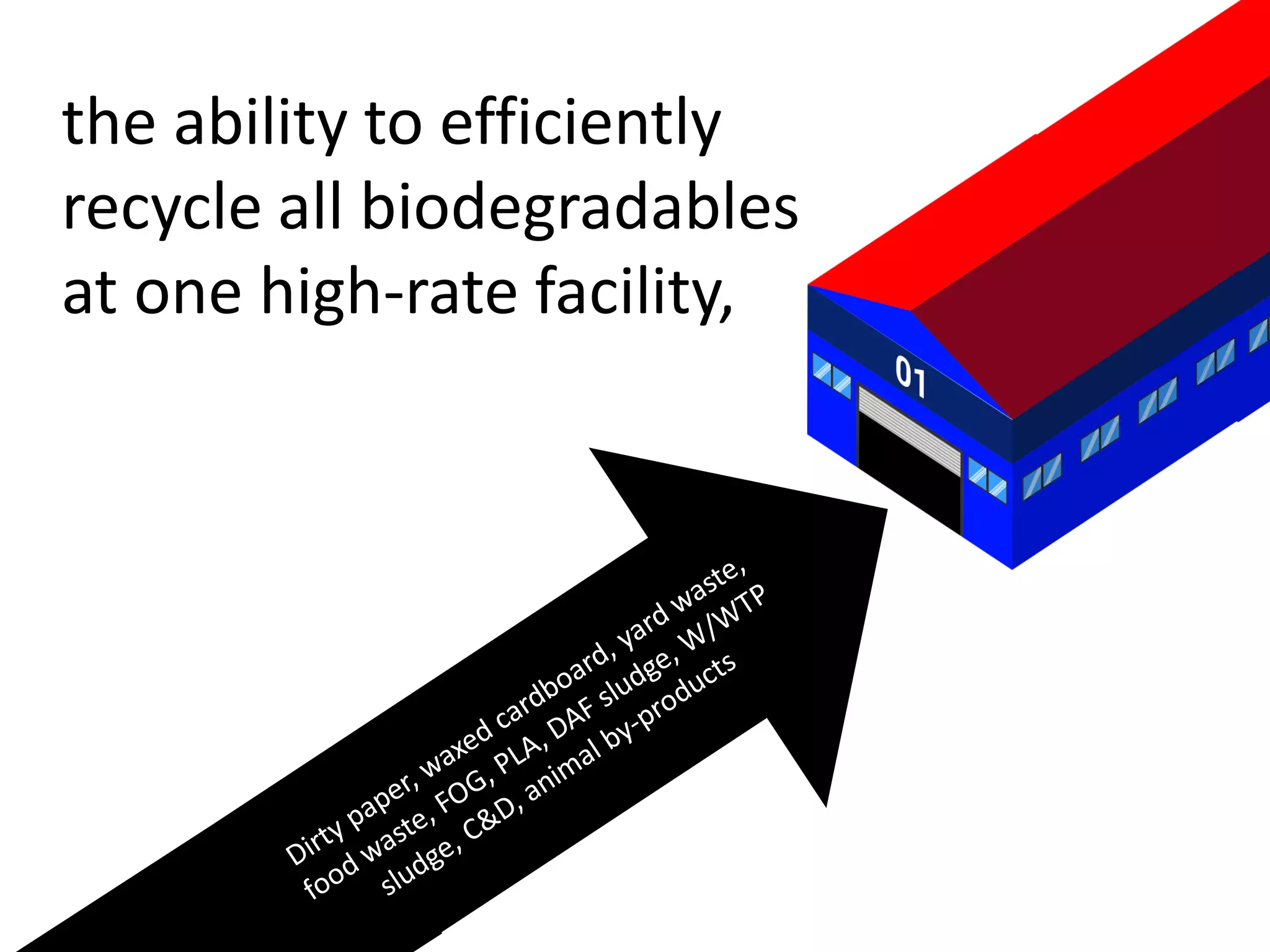

High-rate composting is an advanced method for efficiently managing organic waste in urban areas, operating significantly faster than traditional windrow composting by maintaining optimal temperature controls for aerobic microbes. This modern approach reduces issues like odors, leachate, and dust while enabling the production of high-quality compost, thus meeting regulatory and community expectations. By allowing composting facilities to be located near urban centers, it minimizes transportation costs and enhances profitability, leading to numerous environmental and operational benefits.