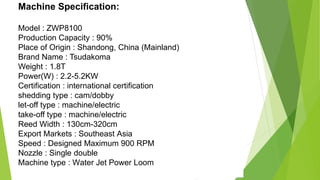

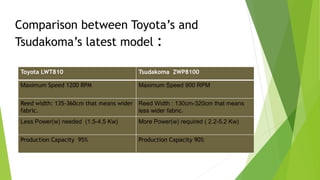

This presentation introduces water jet weaving machines. It provides background on the development of water jet looms in the 1950s in Czechoslovakia and 1960s in Japan. Key features of water jet looms are discussed, including using treated water pumped through nozzles and higher insertion rates than air jet looms. Two modern water jet loom models are compared - the Toyota LWT810 and Tsudakoma ZWP8100. The Toyota model has higher maximum speed, wider fabric width, lower power needs, and higher production capacity.