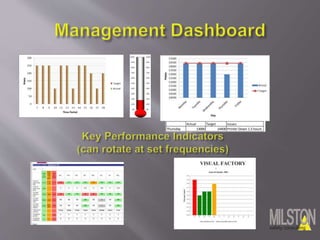

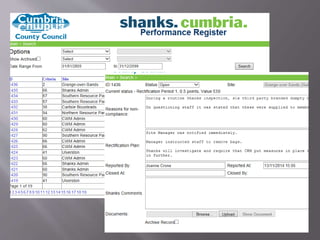

This document describes an innovative low-cost visual performance management software that collects shop floor data quickly and provides feedback on production efficiency. It allows for electronic storage of documents to track key performance indicators and production metrics in real-time on overhead screens. The software is designed to keep implementation costs low and can be accessed via tablets on the factory floor or in boardrooms for live production information and issue highlighting.