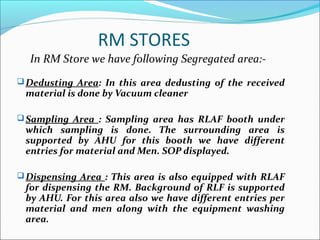

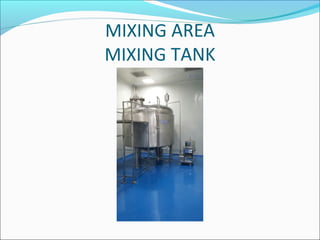

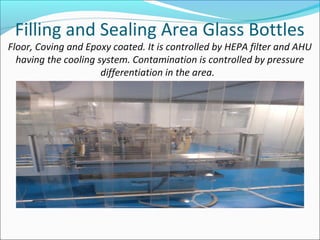

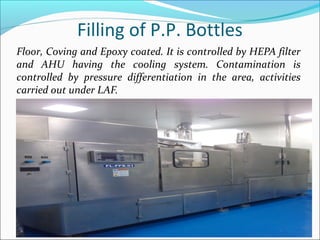

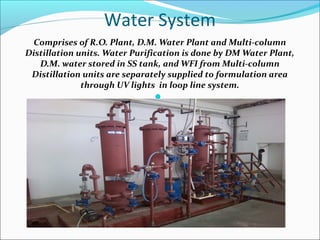

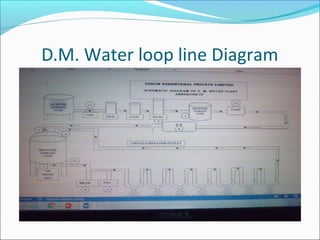

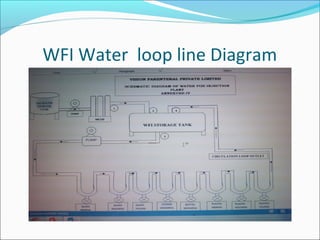

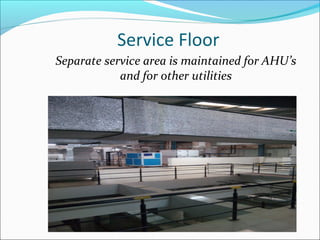

The document describes the facilities and operational areas of Vision Parenteral Pvt. Ltd., located in Gorakhpur, Uttar Pradesh, which manufactures large volume parenterals. It outlines various specialized areas for material handling, quality control, and sterilization processes, emphasizing the importance of contamination control and quality assurance measures in compliance with good manufacturing practices. Additionally, it details the water purification system and HVAC setup to ensure a safe and sterile manufacturing environment.