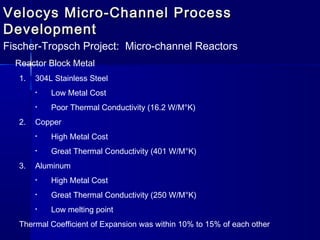

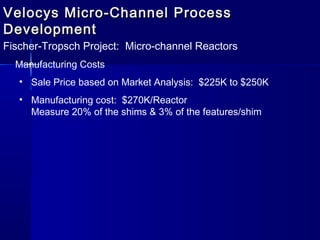

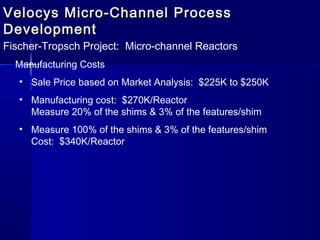

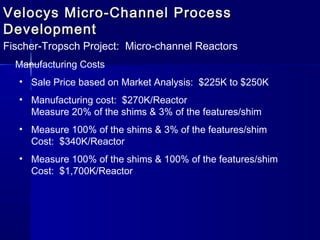

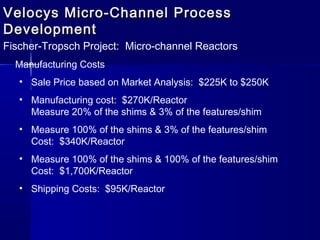

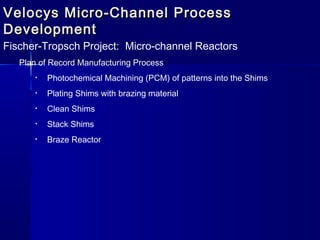

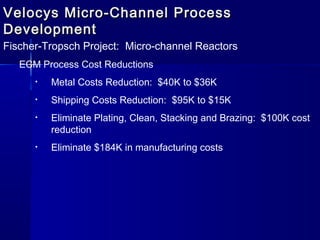

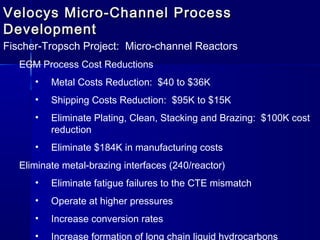

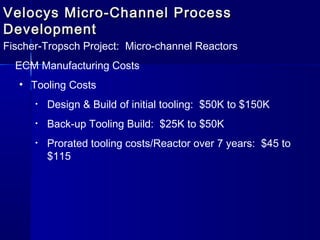

The document discusses Velocys' development of micro-channel reactors for Fischer-Tropsch processes. It describes challenges with the manufacturing process including high costs and inability to meet tight specifications. Initial testing showed reactor productivity was higher than modeled, but the manufacturing process was still not capable of producing acceptable yields. The document recommends identifying alternative manufacturing processes to improve capabilities, reduce costs and further increase reactor productivity.