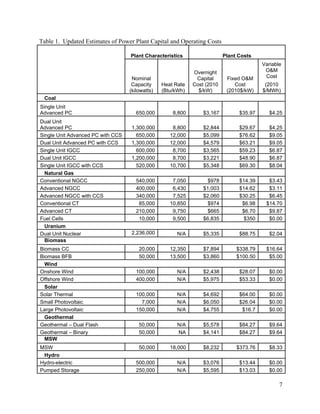

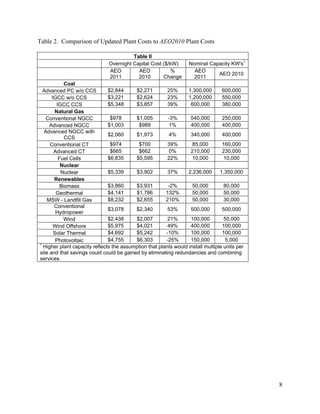

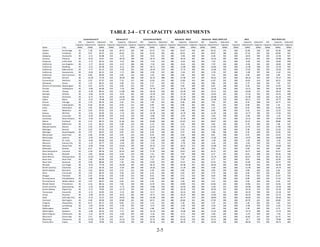

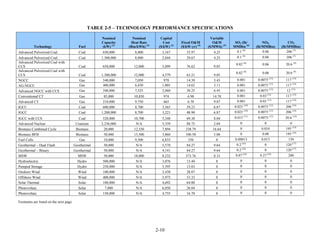

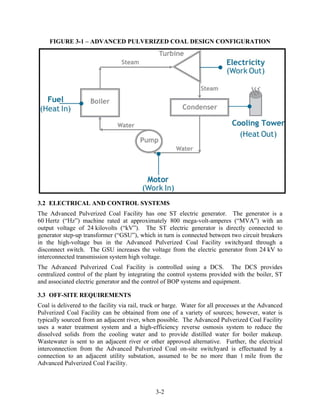

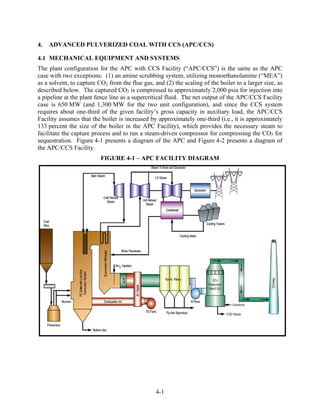

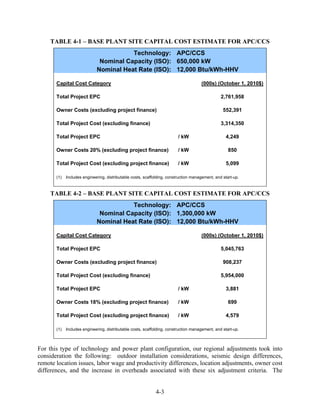

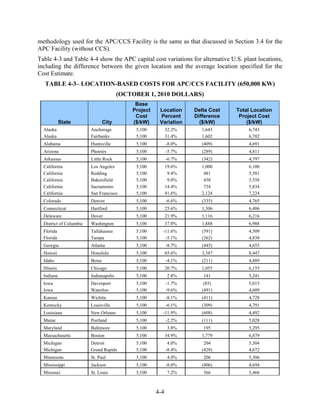

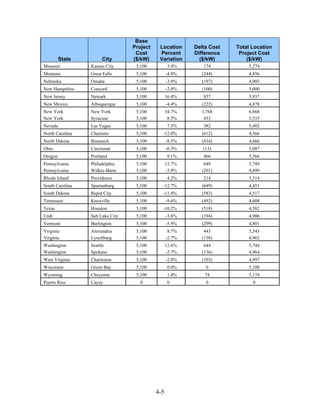

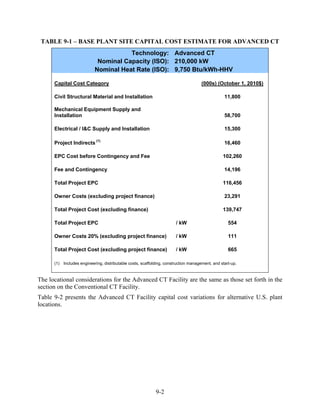

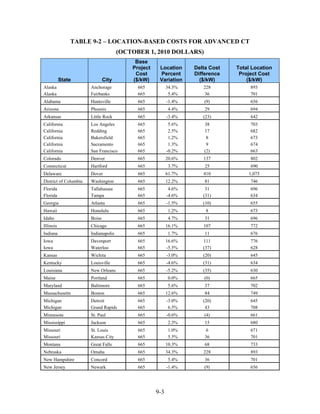

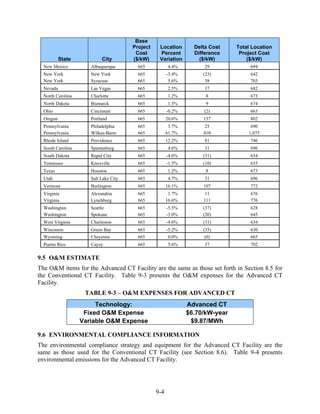

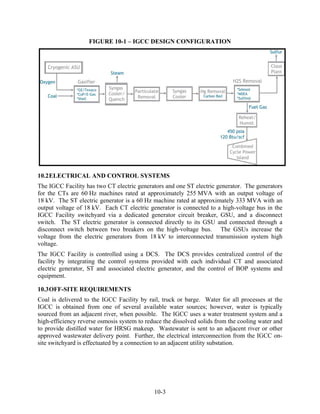

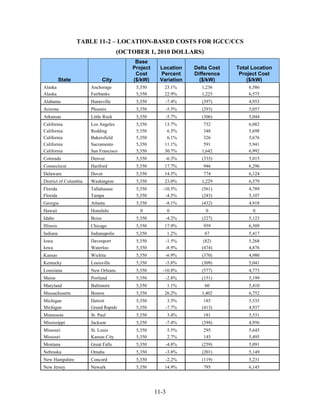

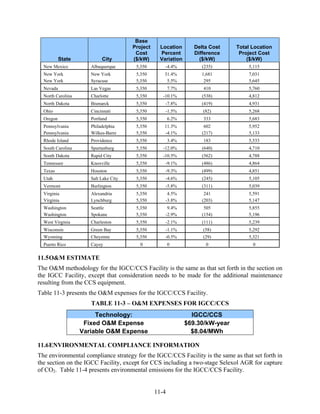

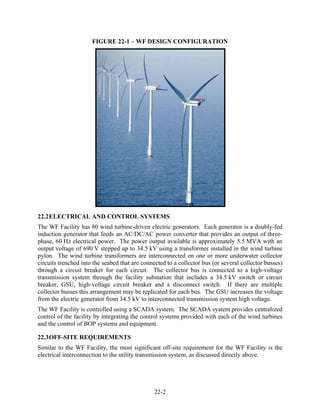

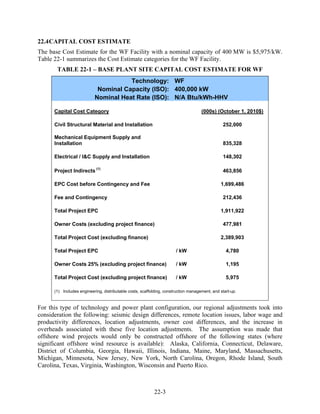

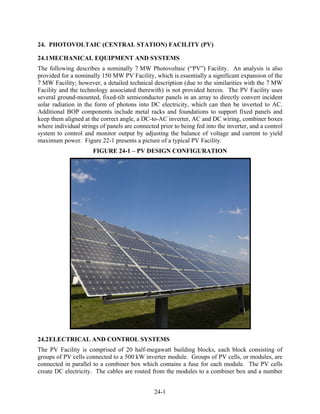

This document summarizes updated capital cost estimates for various electricity generation technologies that were commissioned by the U.S. Energy Information Administration. Key findings include that overnight capital costs for coal and nuclear plants are 25-37% higher than prior estimates, while natural gas costs remained similar. Solar photovoltaic costs declined 25% due to larger plant sizes and lower component costs. Onshore wind costs increased 21%, while offshore wind costs increased 50% to reflect first-of-a-kind U.S. project costs. Geothermal and biomass costs also increased versus prior estimates. These updated cost estimates will be used in EIA's modeling and analysis of technology choices in the electric power sector.