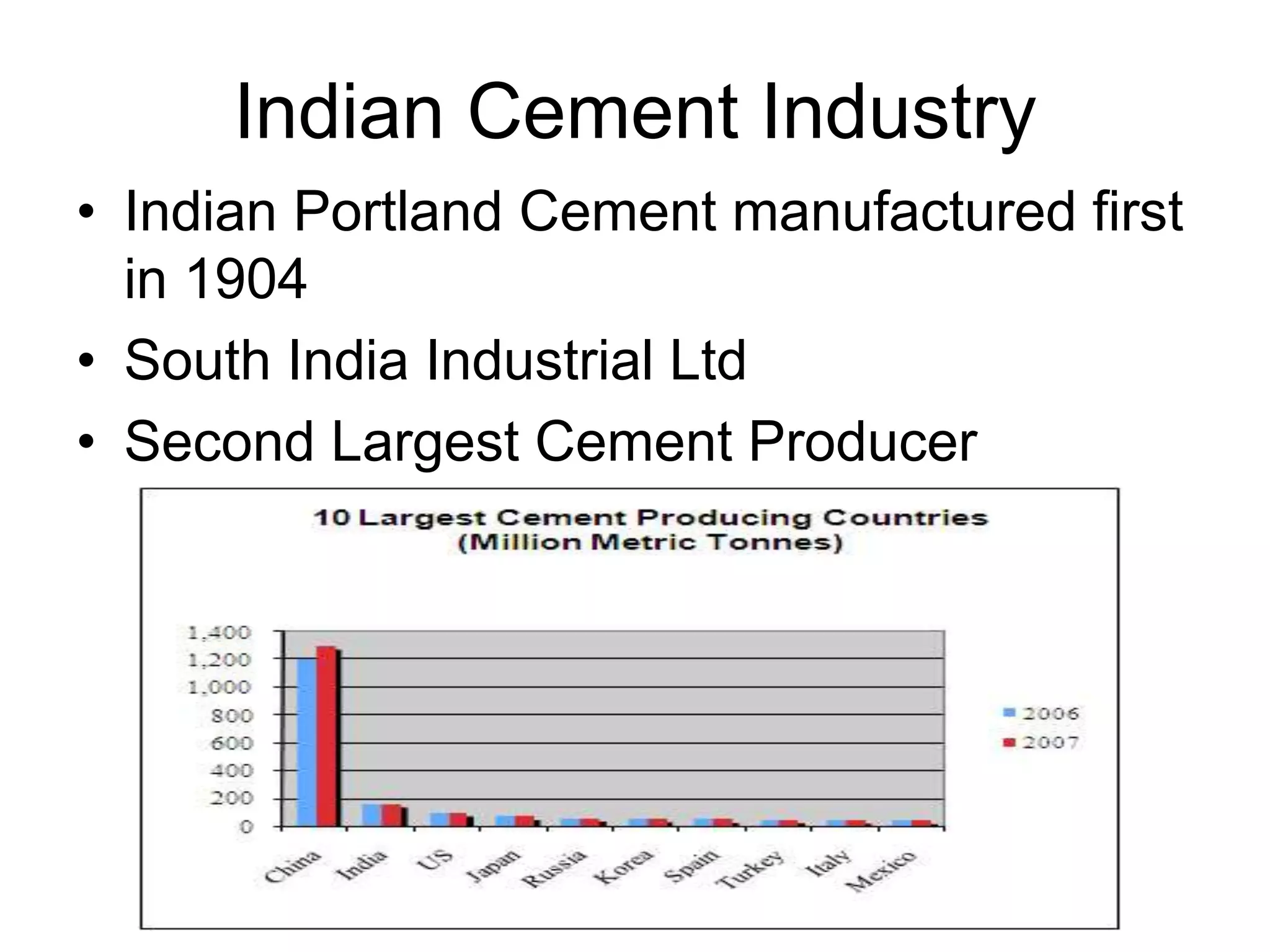

This document provides an overview of cement, including its history, manufacturing process, chemical composition and properties. It discusses the development of cement from ancient times to modern Portland cement. The key points are:

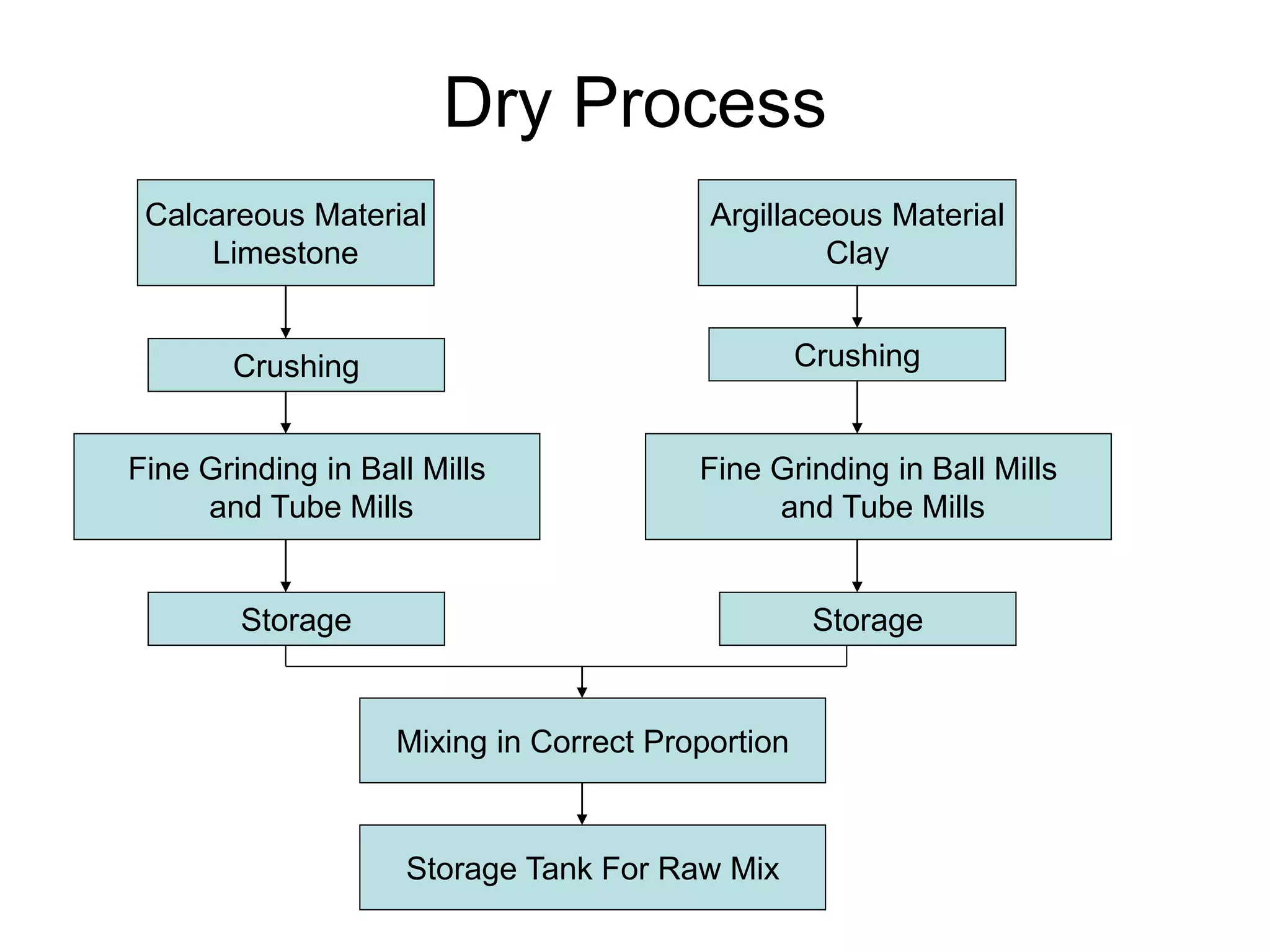

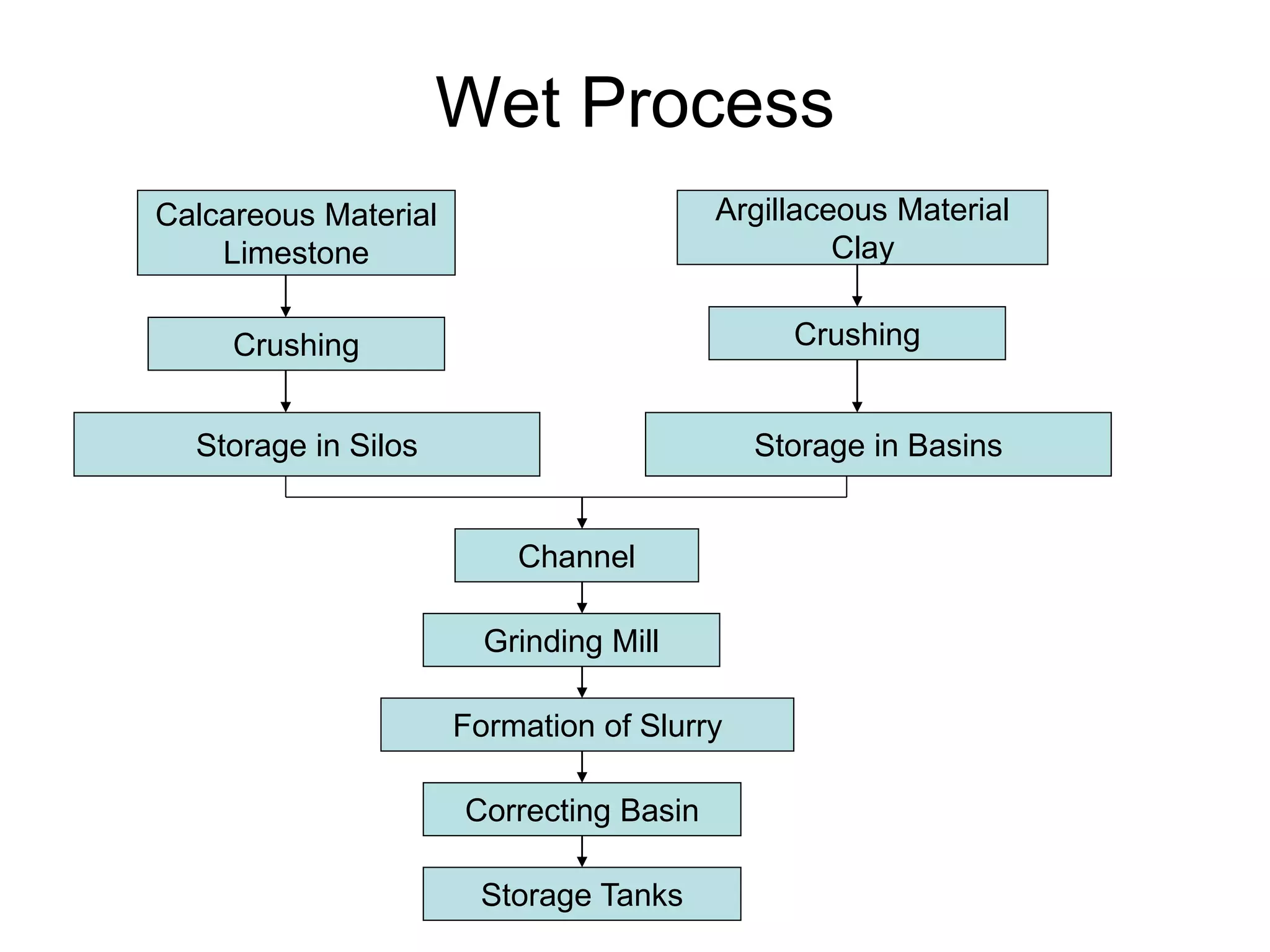

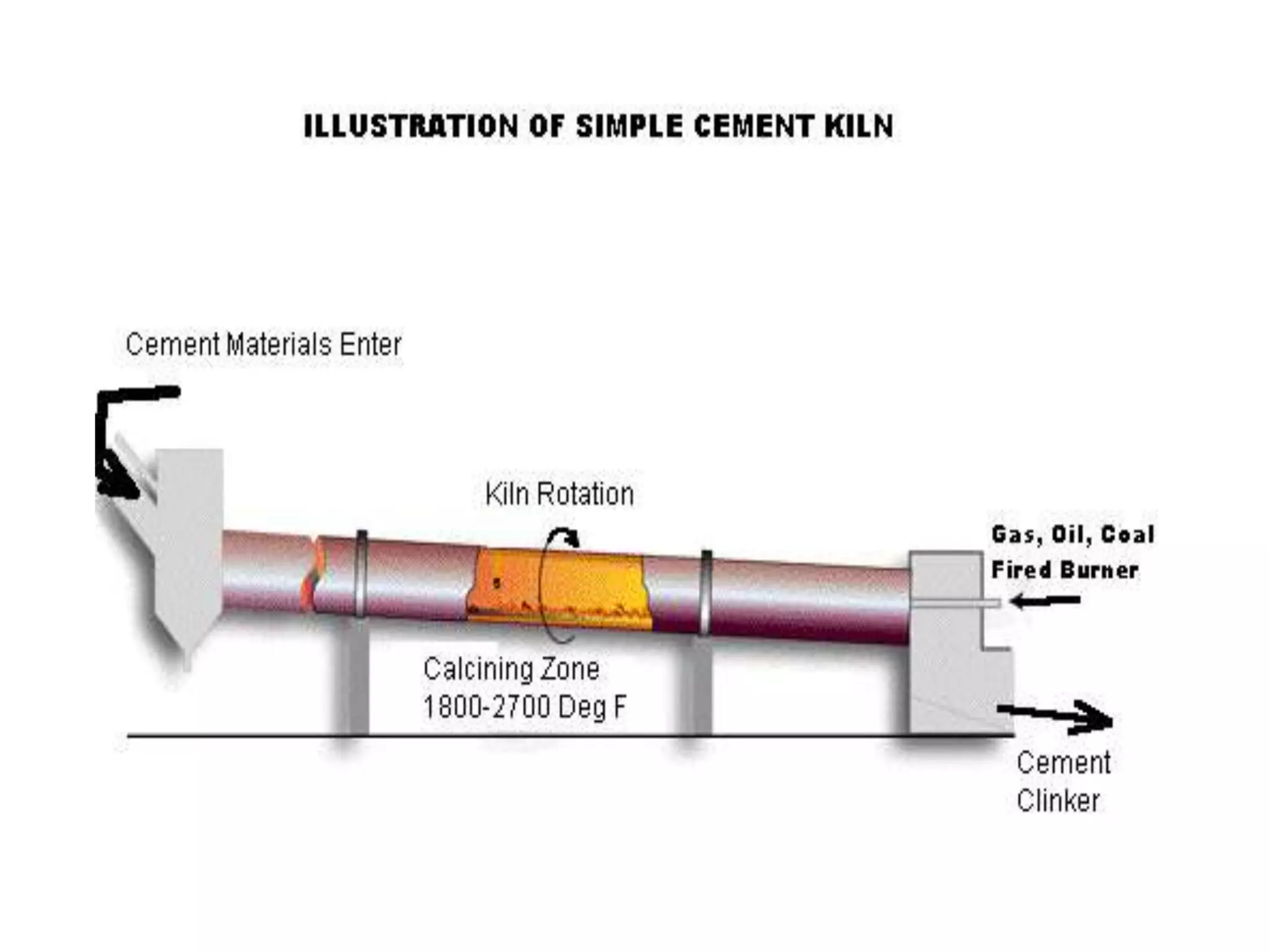

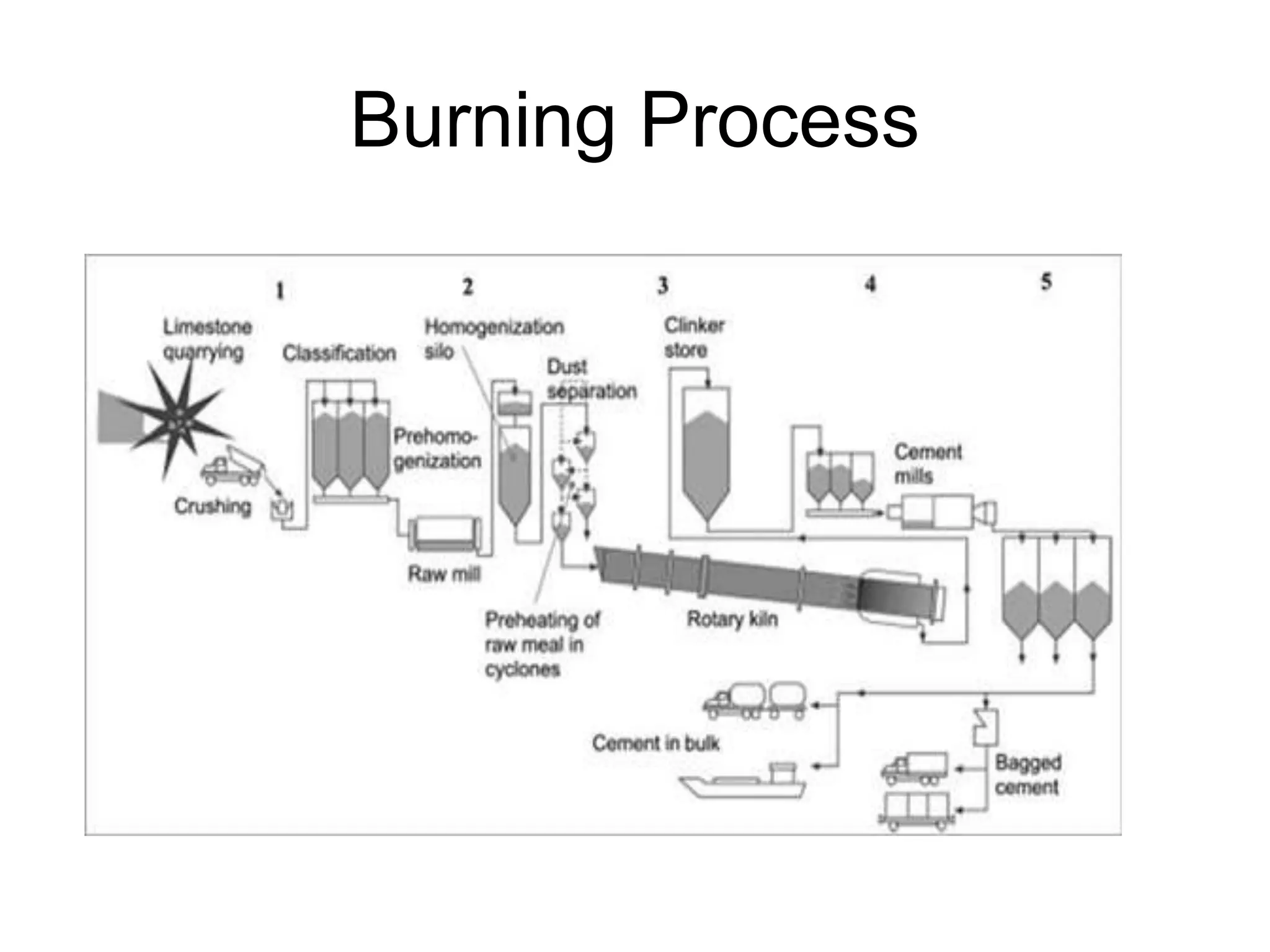

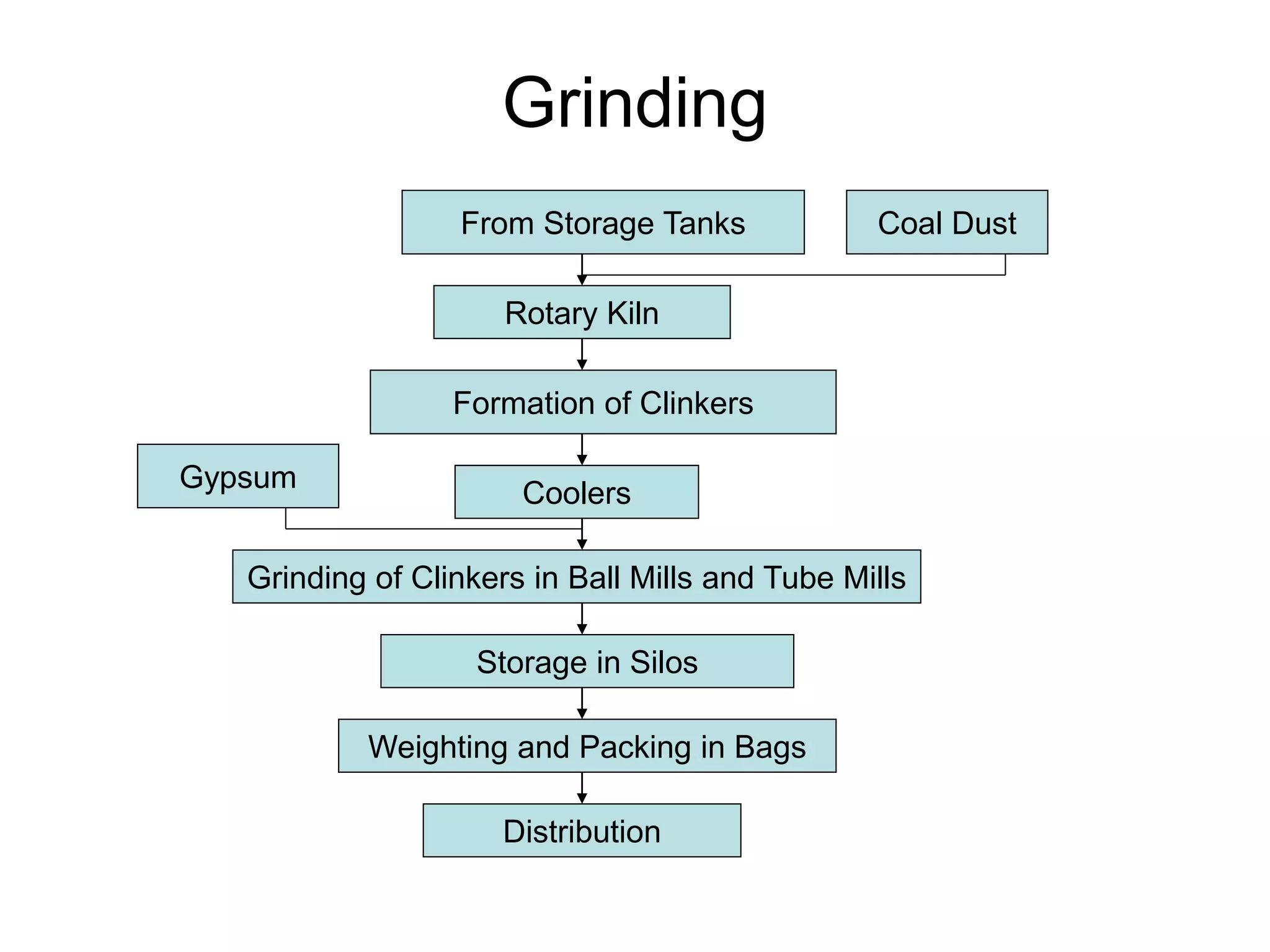

1) Cement is produced through a process of mixing raw materials like limestone and clay, burning them at high temperatures to form clinker, and grinding the clinker into a fine powder.

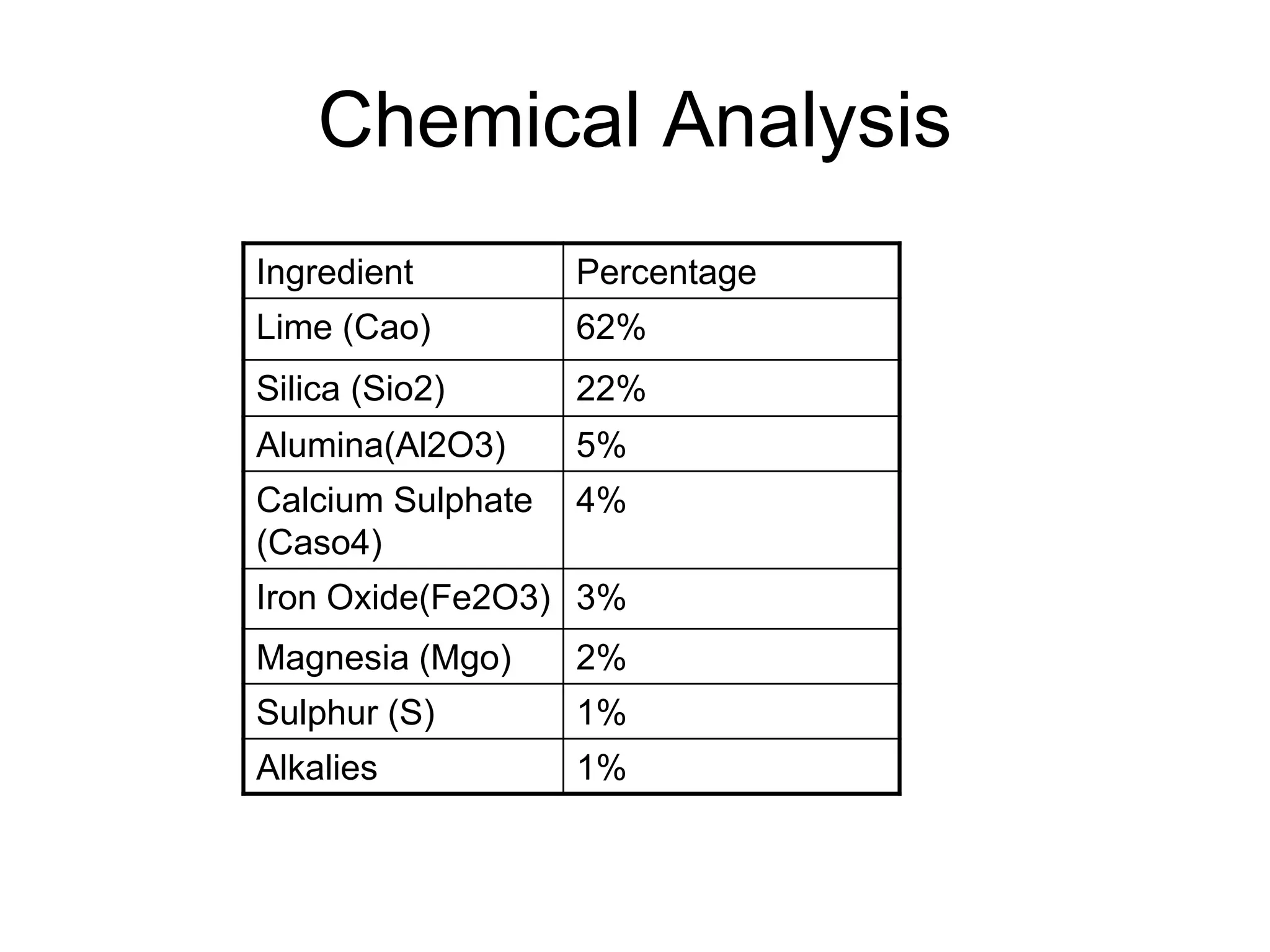

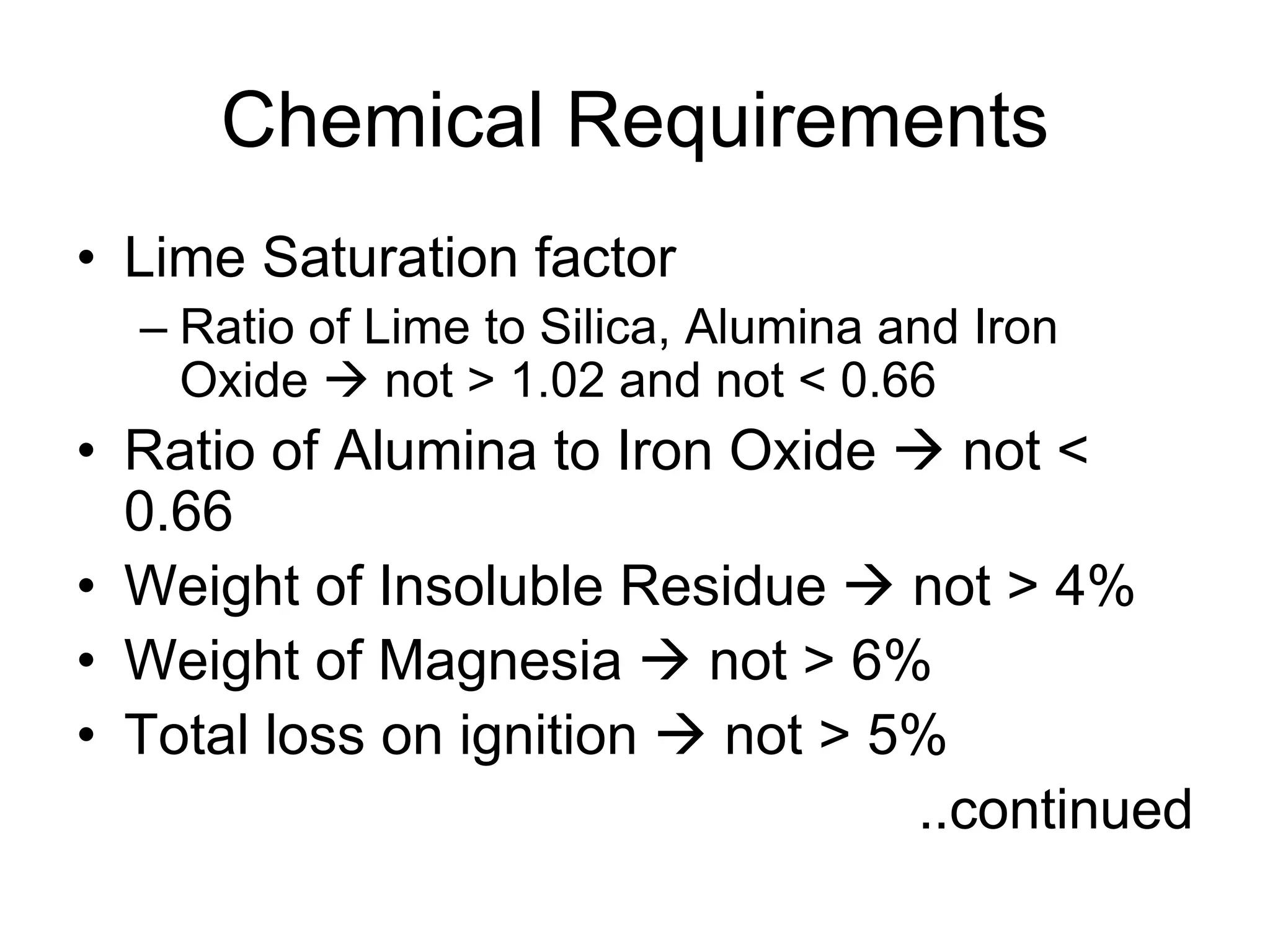

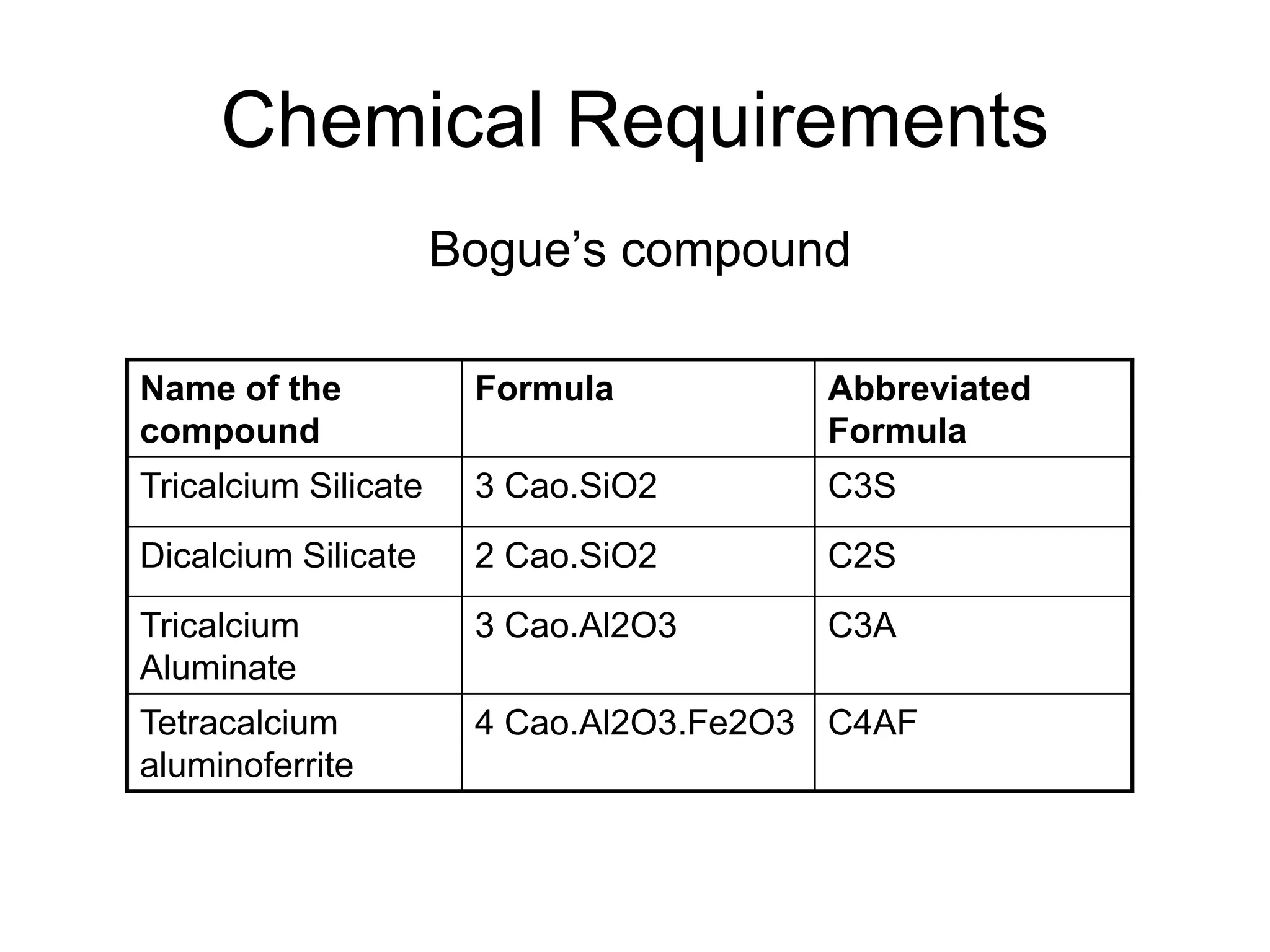

2) Proper chemical composition and ratios of ingredients like lime, silica and alumina are important for cement to set and gain strength over time.

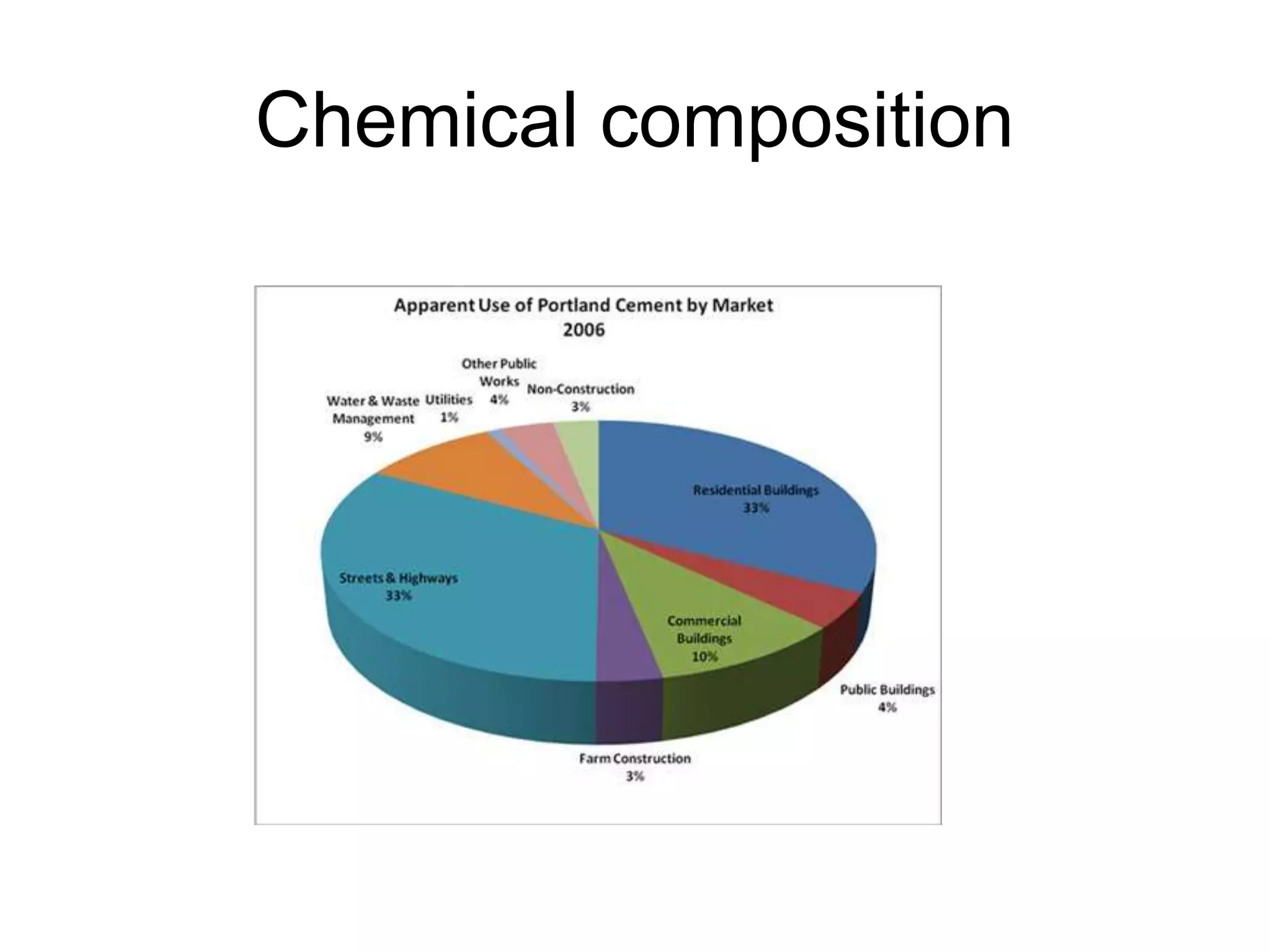

3) The main uses of cement are in construction applications like buildings, roads, and pipes due to its binding properties and ability to harden.