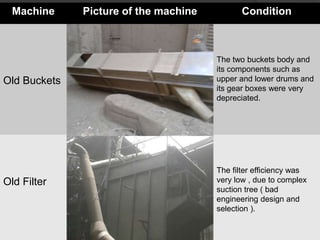

The document outlines a project to overhaul an old mining system by replacing old machines to increase efficiency, durability, and production rate. The old system included a feeder, two bucket elevators, a crusher, screen, and outlet hoppers that were deteriorated. The new system will install a new feeder, bucket elevator, screen, outlet, and hoppers. The maintenance team's scope includes manufacturing new larger hoppers, installing a new electrical panel and control system, adjusting the filter system, and adding new walkways and handrails to simplify movement. This overhaul is estimated to save $80,000 compared to outsourcing the work. The new setup is expected to decrease breakdowns and make equipment movement easier