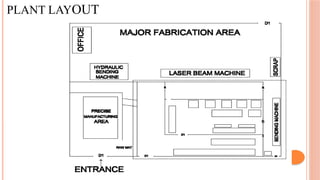

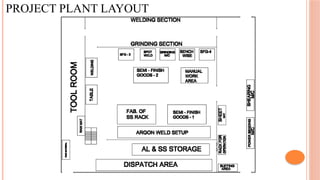

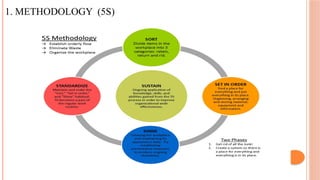

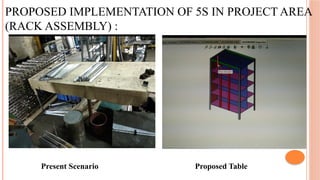

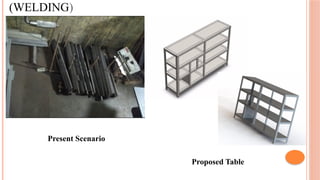

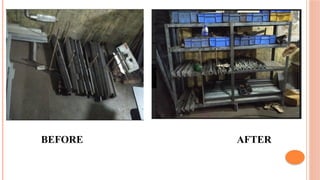

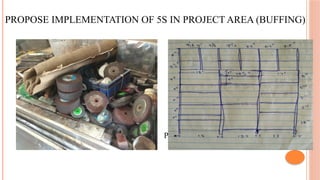

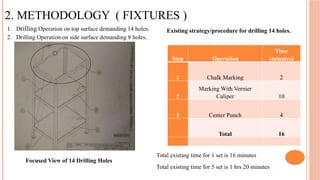

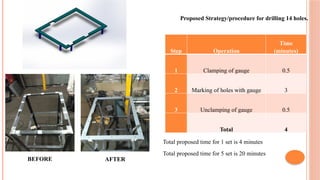

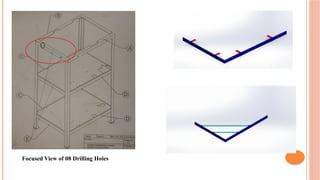

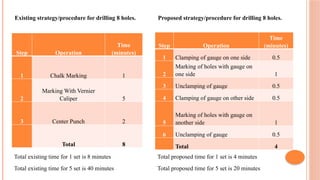

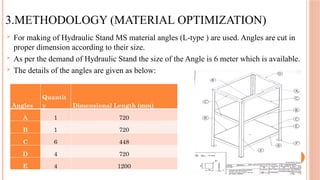

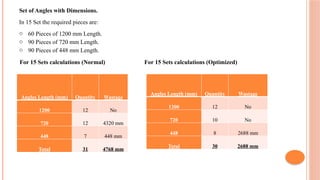

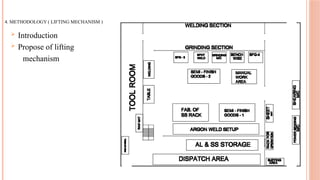

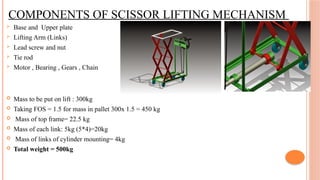

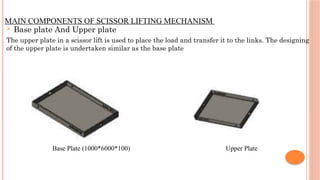

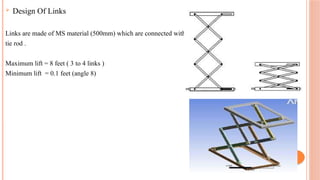

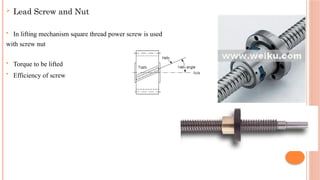

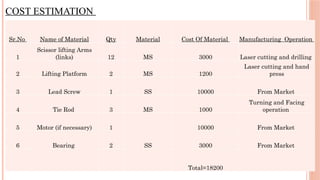

The document outlines a project on the implementation of 5S and improvement methodology at Fledon Engineering Works to address issues related to workspace utilization, material handling, and production costs. It details various methodologies, including plant layout improvements, material optimization, and the design of a scissor lifting mechanism, with aimed outcomes of reducing manufacturing cycle times, increasing productivity, and enhancing safety. The project concludes that effective implementation of these techniques can significantly enhance productivity and streamline material flow while optimizing storage space.