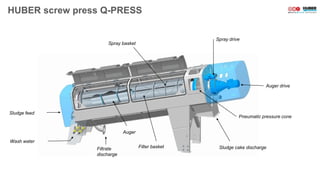

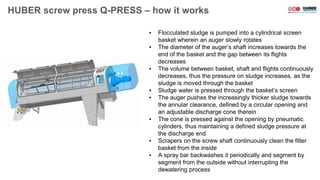

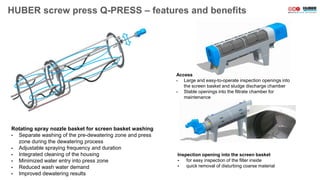

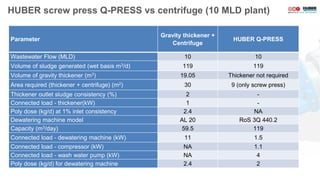

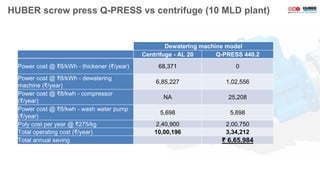

The Huber Screw Press Q-Press is an efficient sludge dewatering solution that eliminates the need for prior thickening, achieving 18-25% dry solids and over 97% volume reduction with minimal operator attention. It features low power consumption, a low rotation speed for reduced wear, and integrated cleaning systems to optimize performance. A.T.E. Huber Envirotech, leveraging 180 years of experience, provides advanced wastewater treatment solutions across various industries.