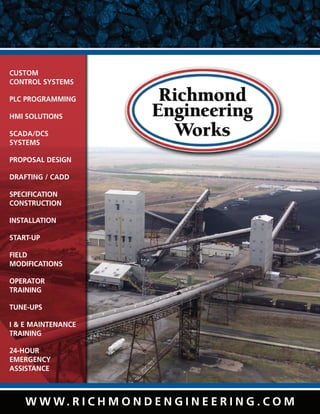

This document describes Richmond Engineering Works' services including PLC programming, HMI solutions, SCADA/DCS systems, engineering design, construction, installation, training, and maintenance. It provides examples of projects involving upgrades to clamshell unloaders, coal yard operations, ancillary power plant systems, and lists customer companies served. Richmond specializes in custom control systems for manufacturing, bulk material handling, and material handling equipment.