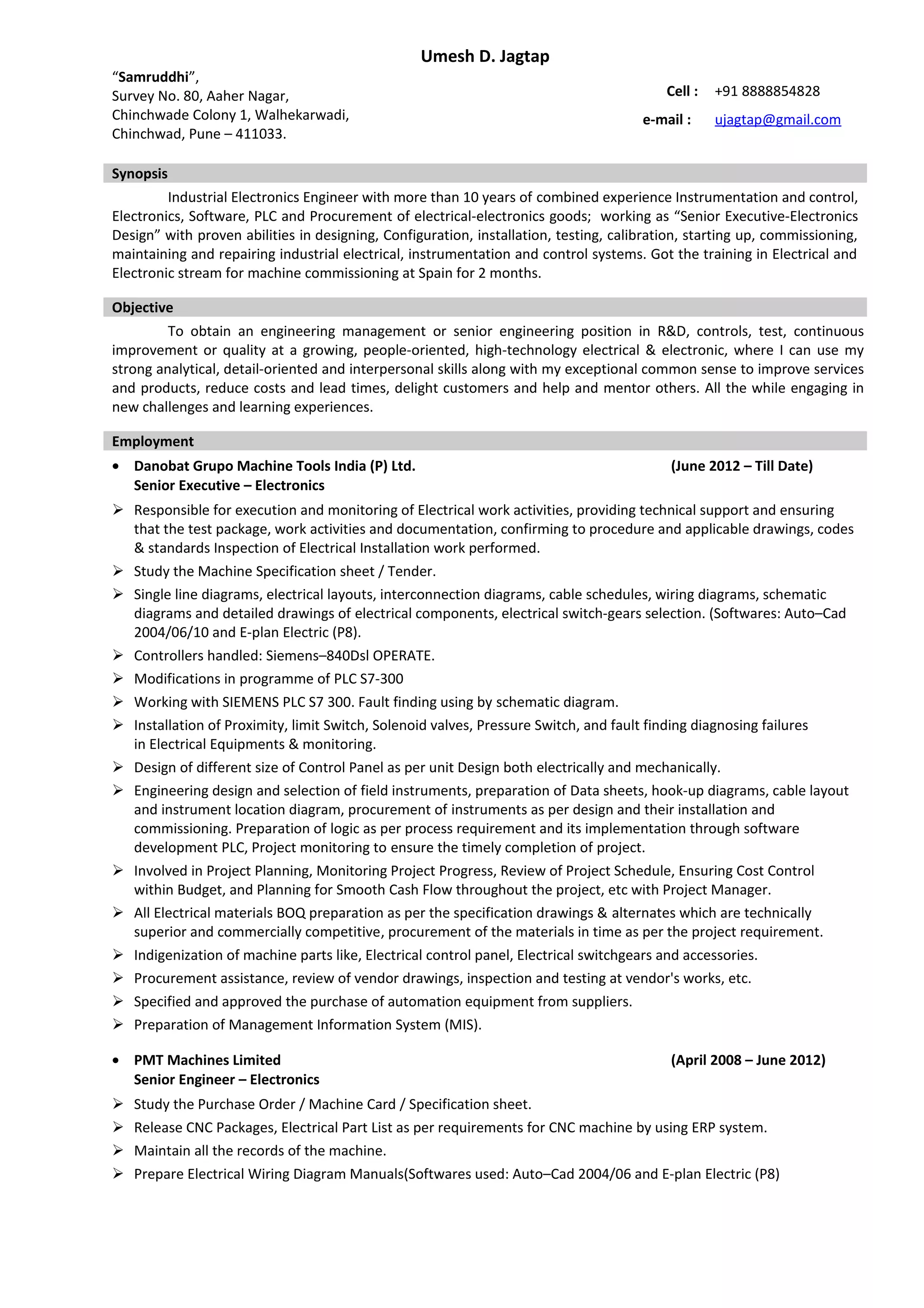

Umesh D. Jagtap is an industrial electronics engineer with over 10 years of experience in electrical systems, instrumentation, and control. Currently a Senior Executive at Danobat Grupo, he specializes in executing and monitoring electrical projects, designing control systems, and managing procurement. His objective is to secure a senior engineering position where he can leverage his analytical and interpersonal skills for continuous improvement in a high-technology environment.