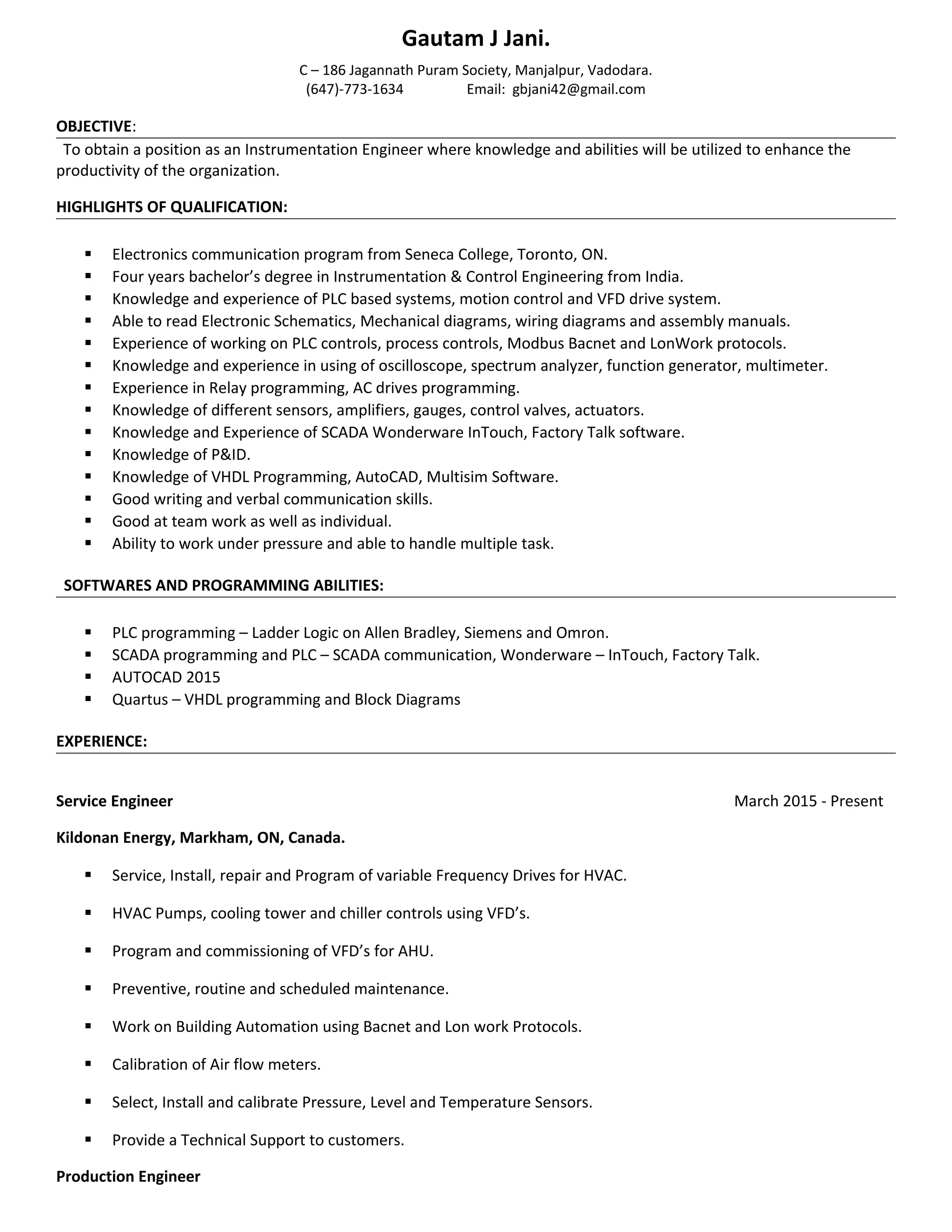

Gautam J Jani is seeking a position as an Instrumentation Engineer with experience in PLC programming, SCADA systems, process controls, and building automation. He has a certificate in PLC programming and a bachelor's degree in Instrumentation and Control Engineering. His experience includes programming VFD drives, sensors, and control systems for HVAC, manufacturing, and water treatment facilities.