This document provides an overview of ITI Limited, an Indian state-owned manufacturer of telecommunications equipment. It discusses ITI's profile, facilities, products, customers, and power distribution system. Some key points include:

- ITI was established in 1948 and has six manufacturing facilities producing switching, transmission, access, and subscriber equipment.

- It produces GSM mobile equipment and supplies over nine million lines annually to domestic and export markets.

- ITI's Naini facility in Allahabad manufactures telecom transmission equipment and telephone instruments to build India's telecom infrastructure.

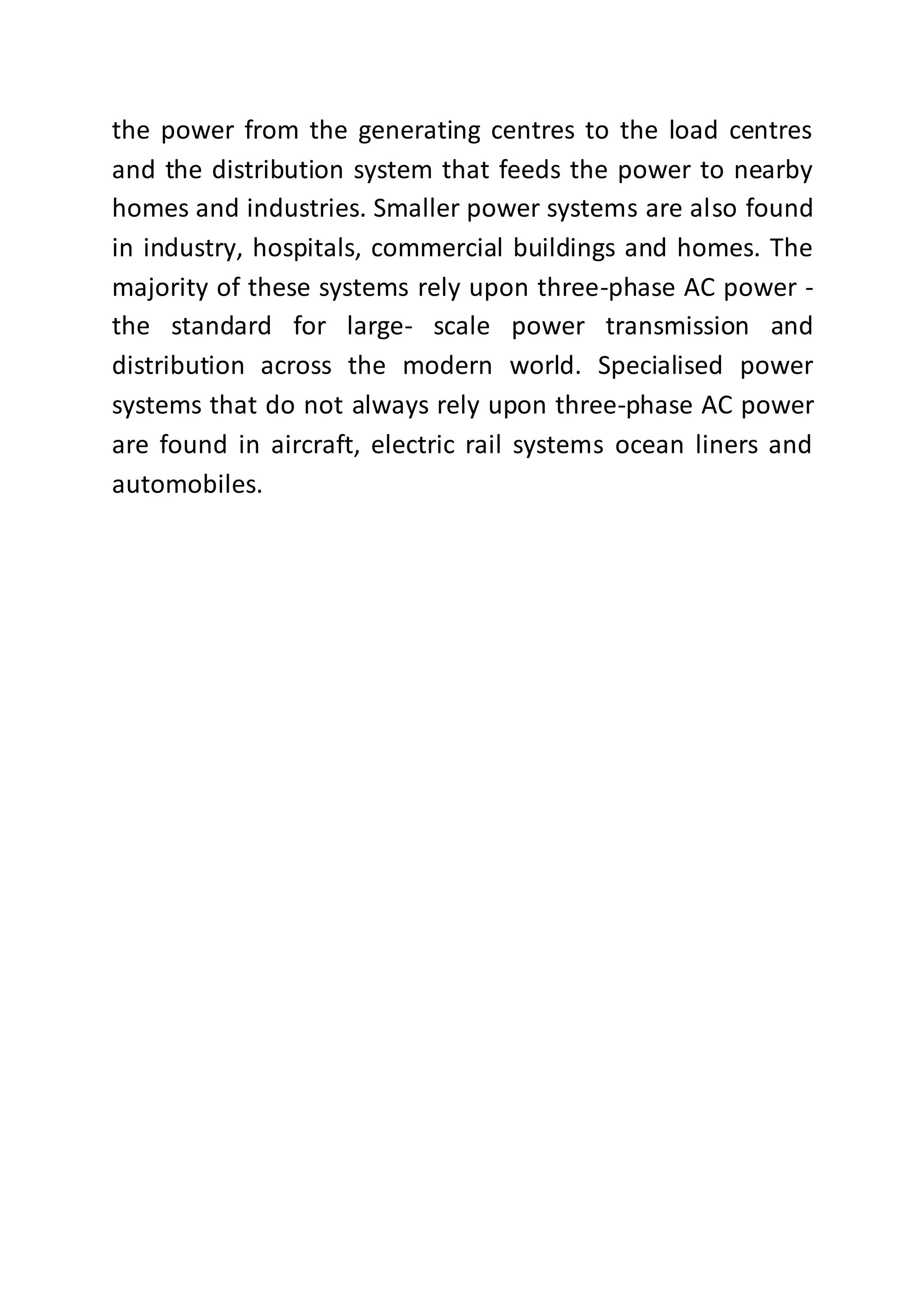

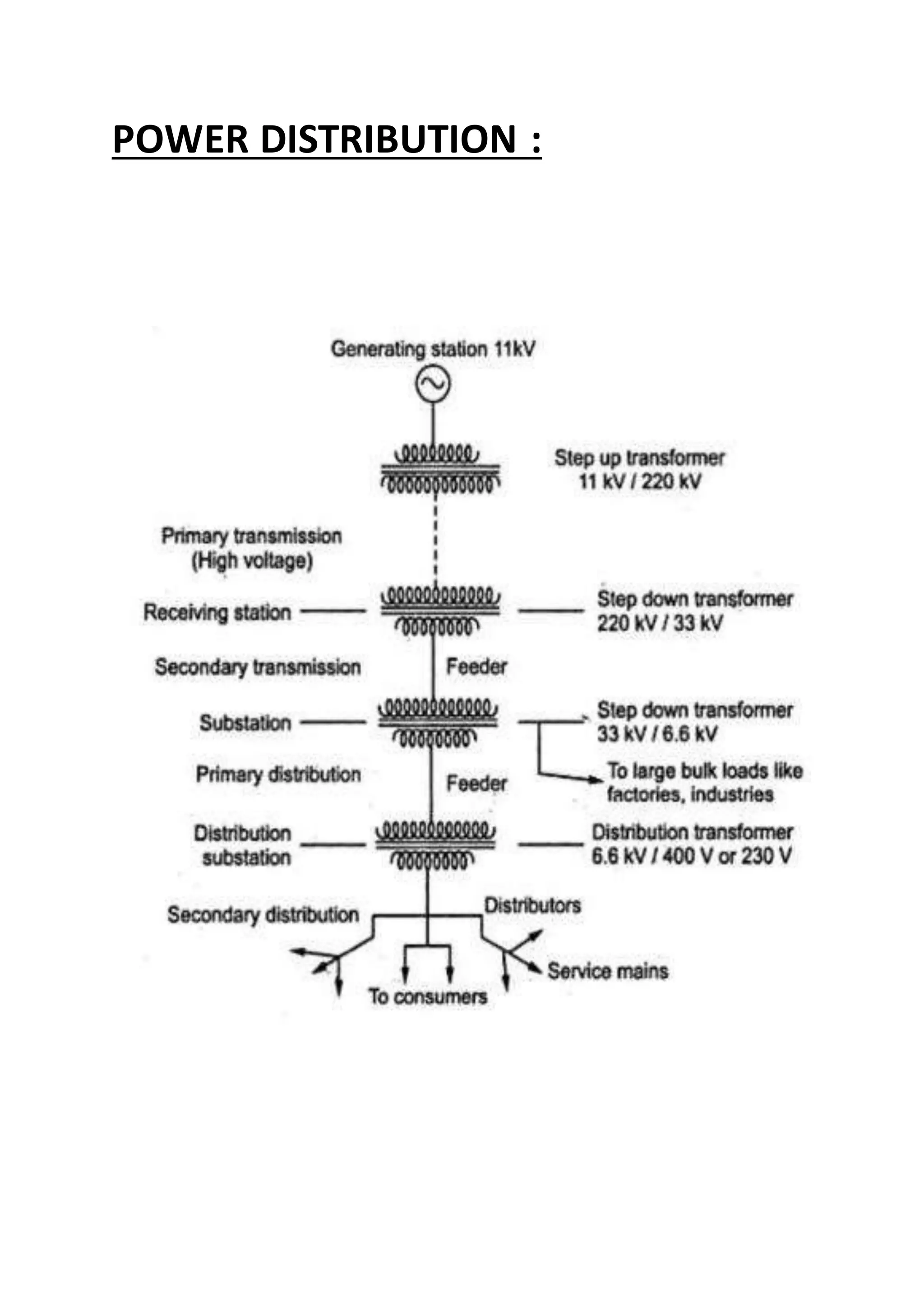

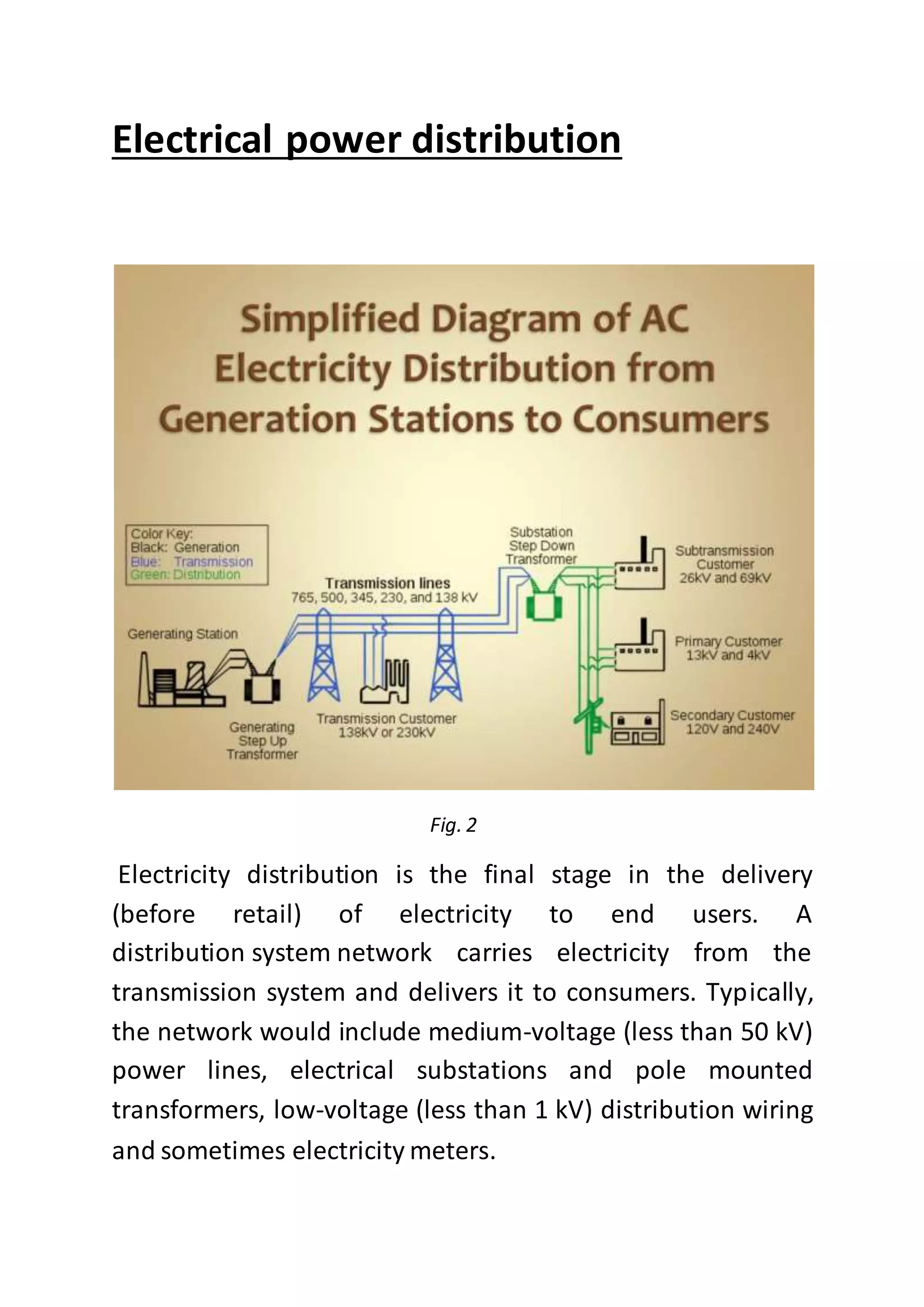

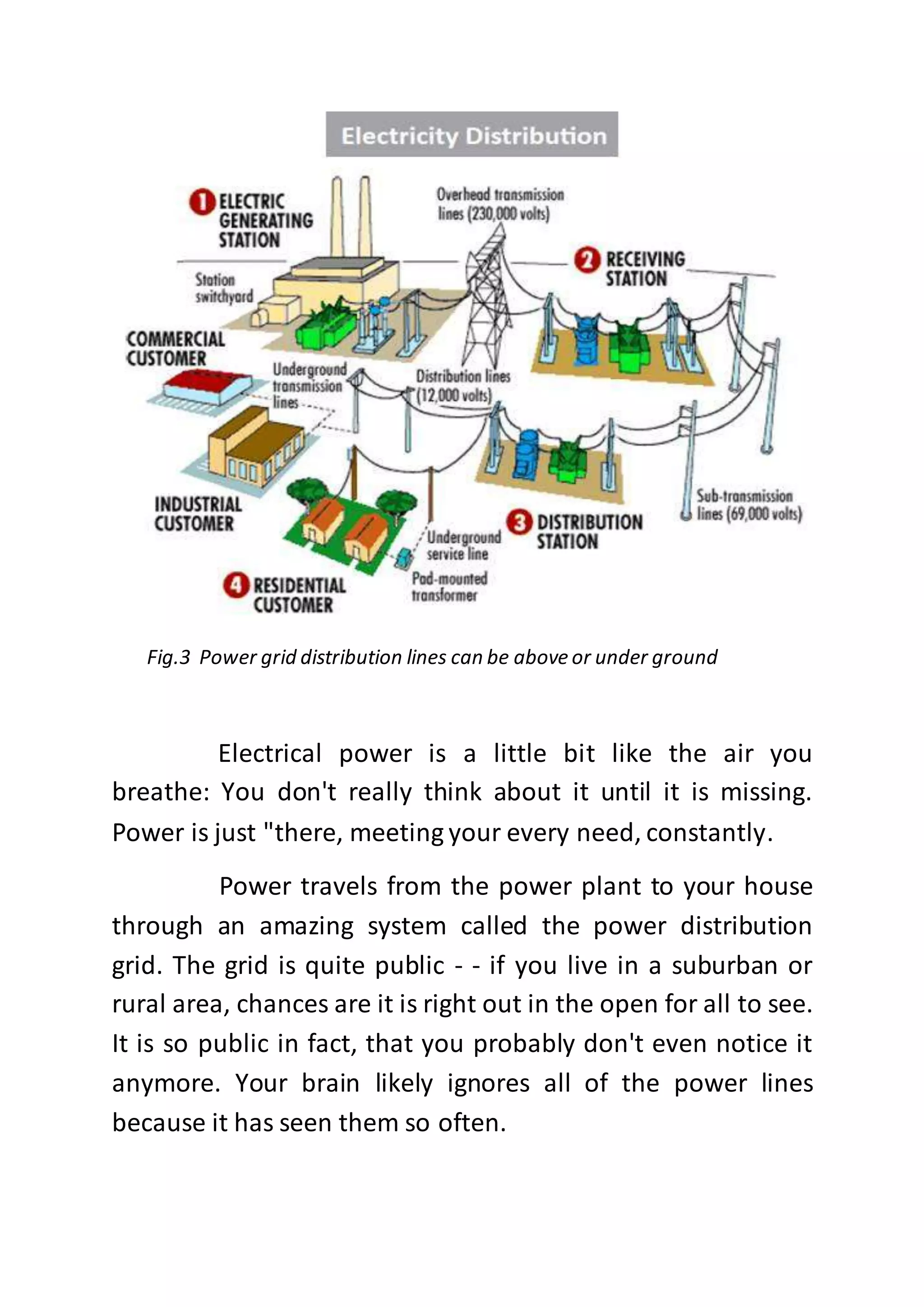

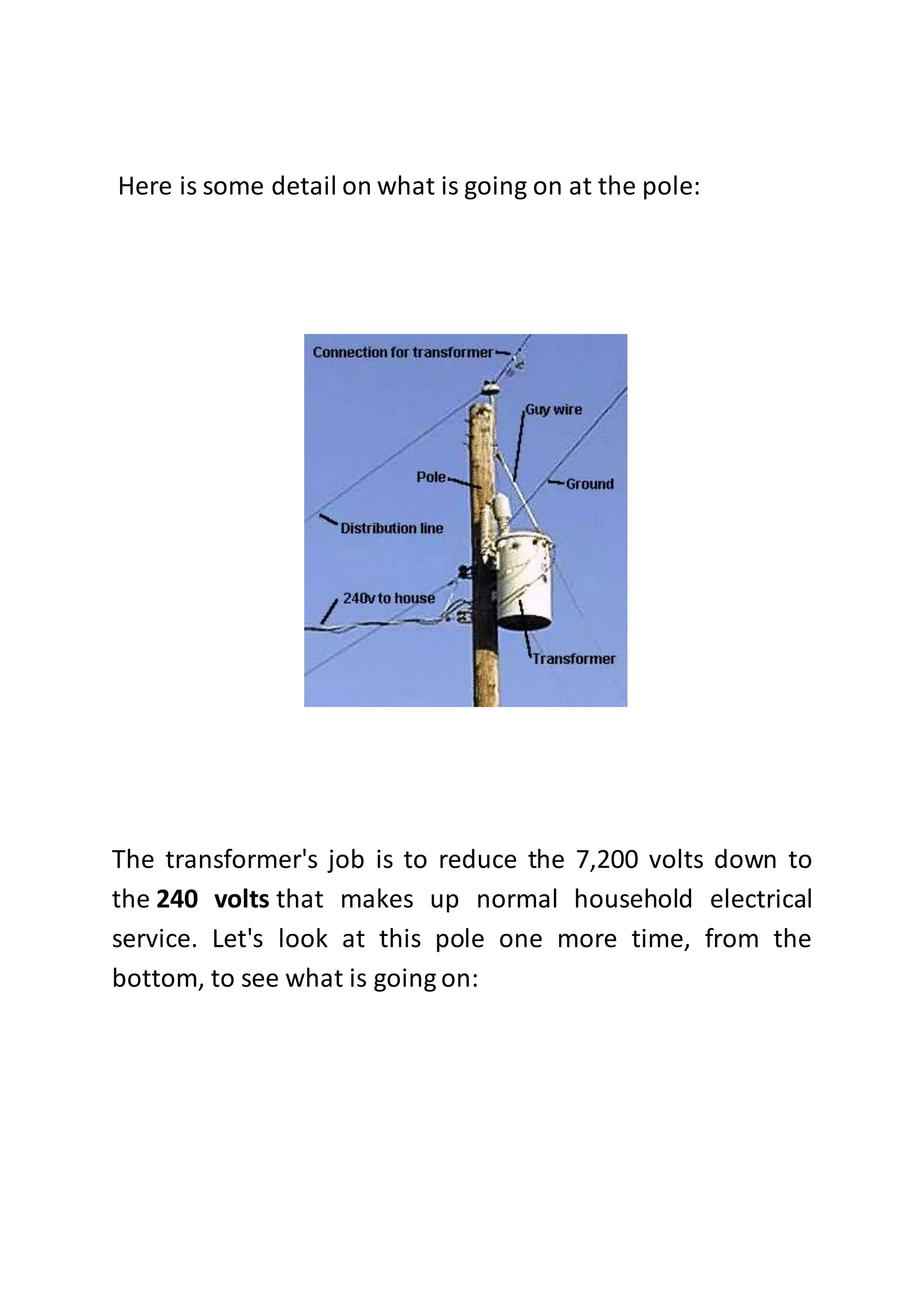

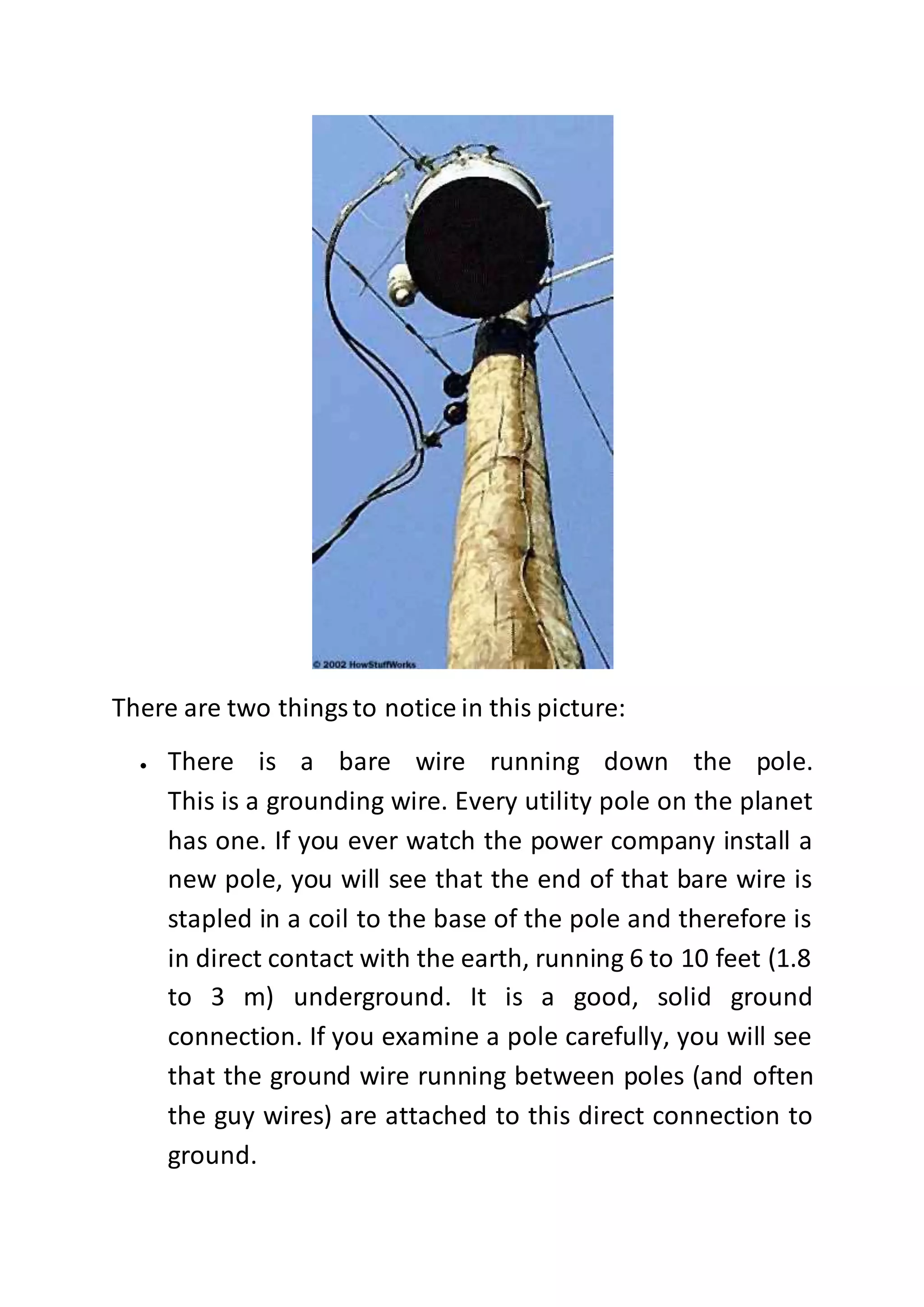

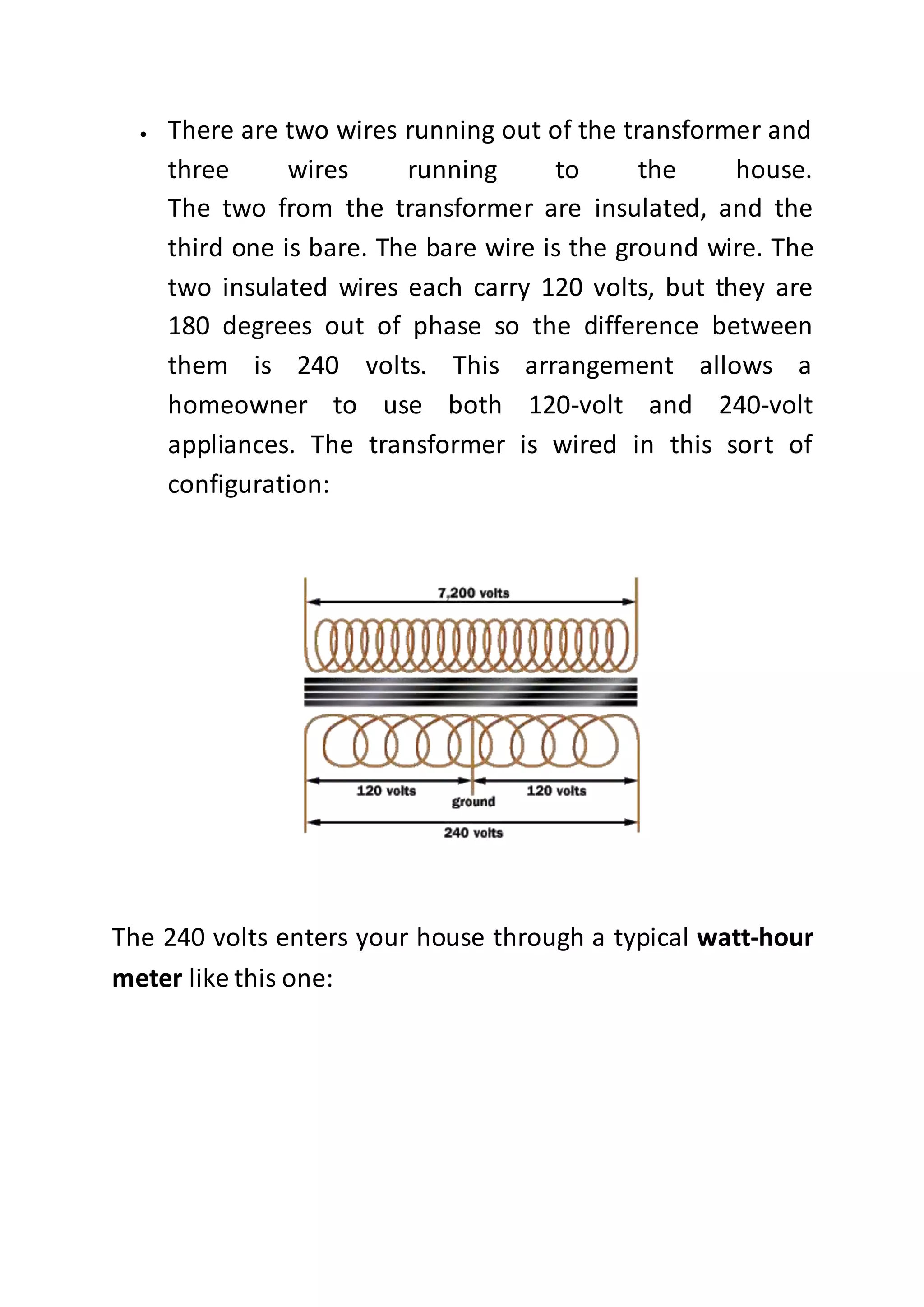

- The document outlines ITI's electricity distribution network within its facilities.