The document provides details about Atul Malhotra's semester training at Swaraj Engines Limited in Mohali, India. It includes:

- An introduction to Swaraj Engines Limited, describing its establishment and production of diesel engines.

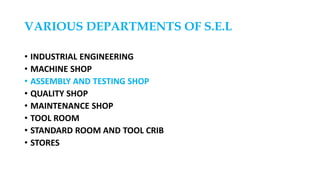

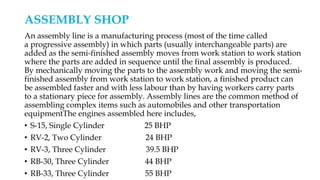

- An overview of the various departments, including the Assembly Shop where Atul was trained.

- Details of Atul's objectives for the training, which were to gain new skills, study processes, and complete projects under supervision.

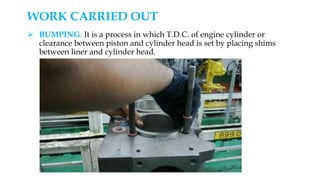

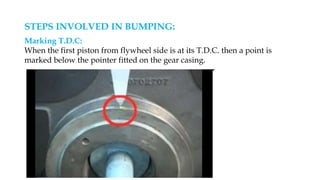

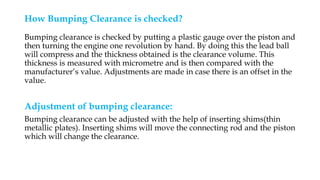

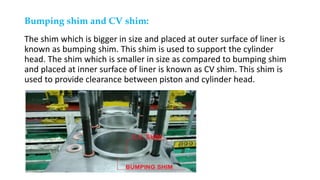

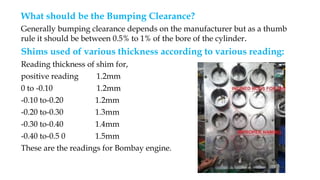

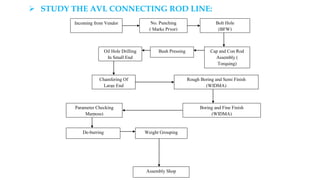

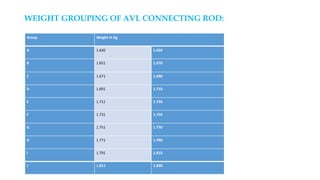

- A description of key tasks Atul carried out, such as analyzing the bumping process to set piston clearance and studying the production line for connecting rods.

![ASSEMBLY PROCESS FOLLOWED AT SHOP

• CRANK SHAFT FITMENT

• CAM SHAFT FITMENT

• GEAR CASING FITMENT

• CRITICAL AREA PISTON ASSEMBLY

• CYLINDER BLOCK FITMENT

• OIL SUMP FITMENT

• CYLINDER HEAD FITMENT

• WATER PUMP FITMENT

• FIP [FUEL INJECTION PUMP] FITMENT

• FUEL TIMING](https://image.slidesharecdn.com/f65e0ca5-83cd-4deb-88ad-6d6f519969d1-150710071234-lva1-app6891/85/training-ppt-6-320.jpg)