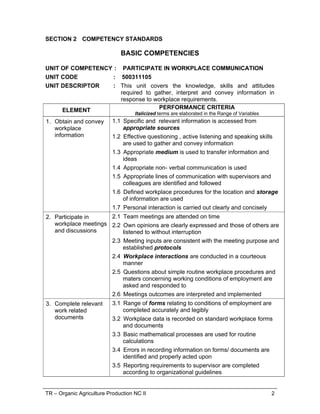

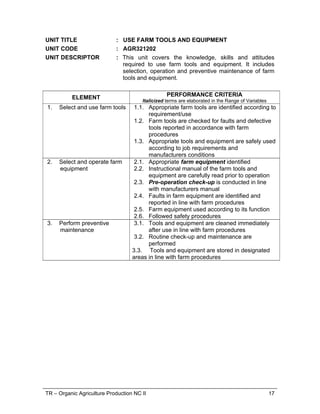

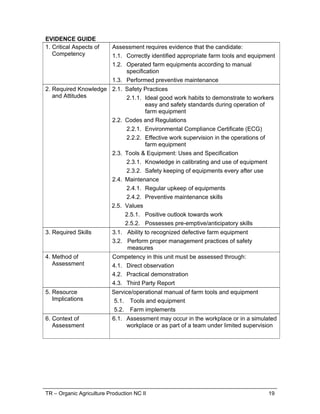

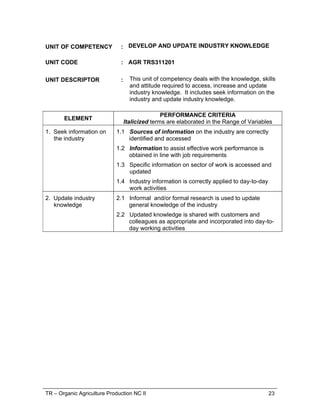

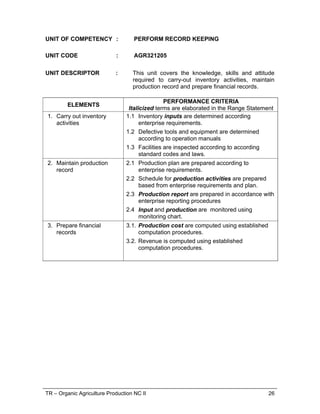

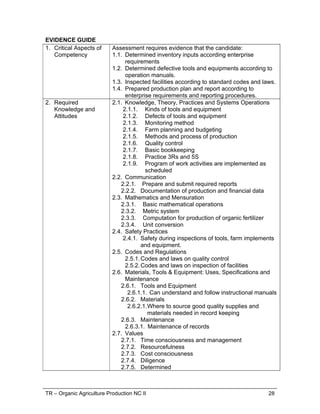

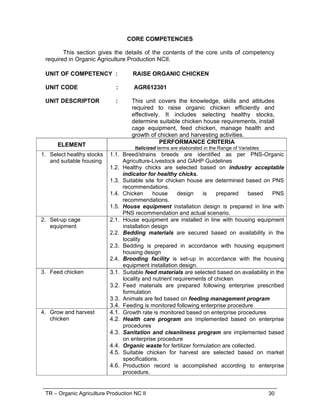

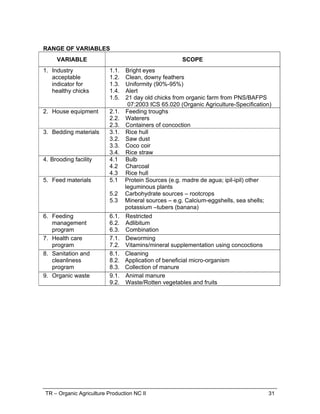

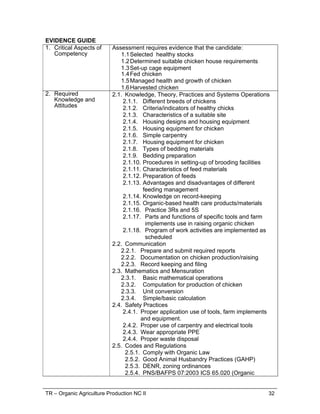

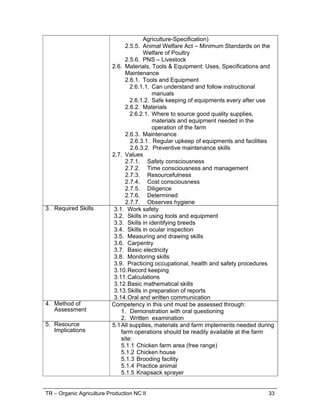

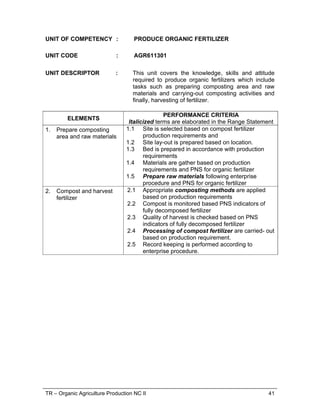

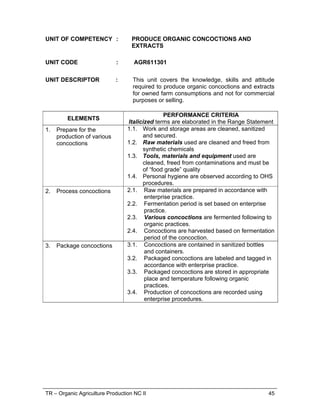

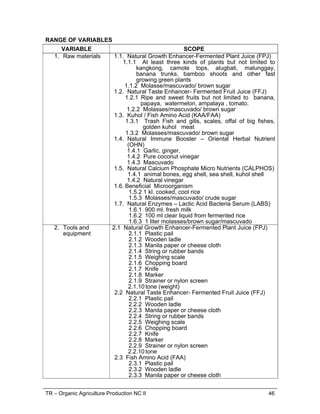

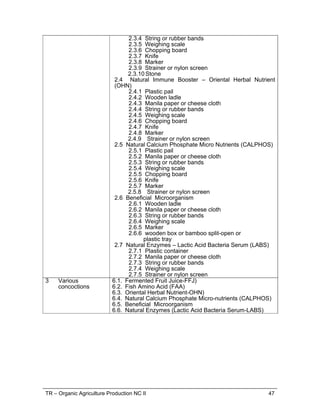

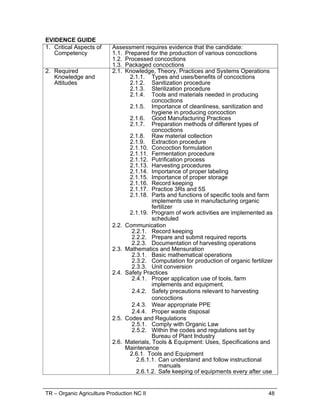

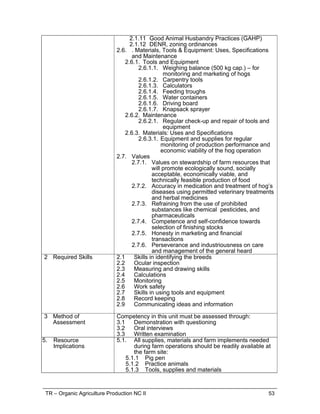

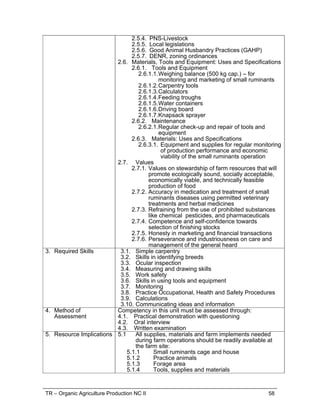

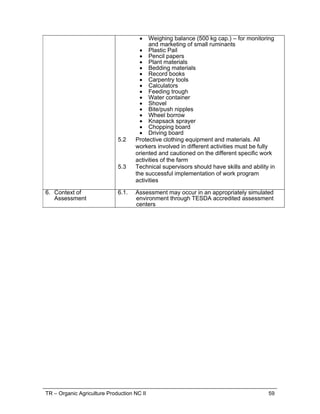

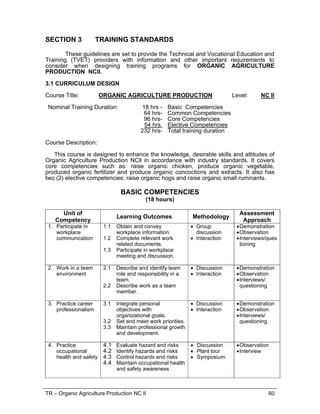

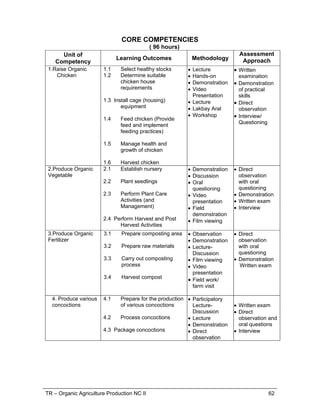

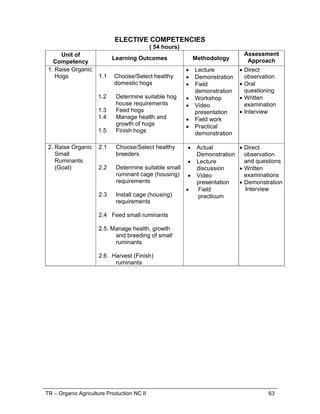

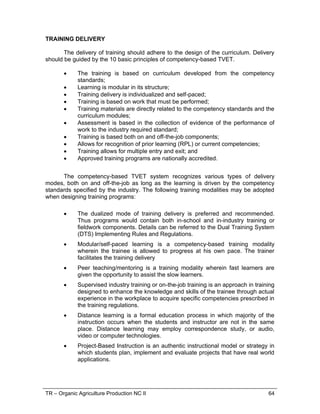

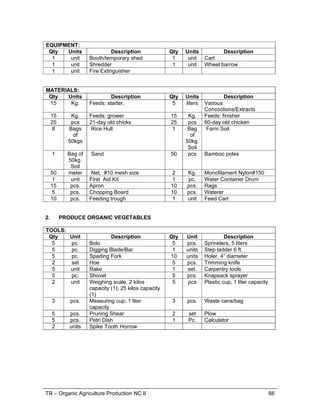

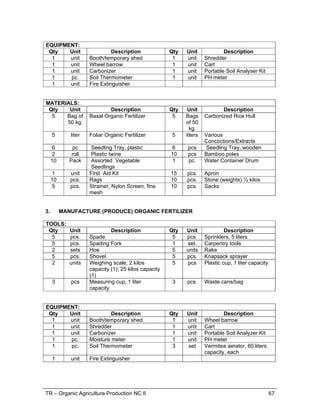

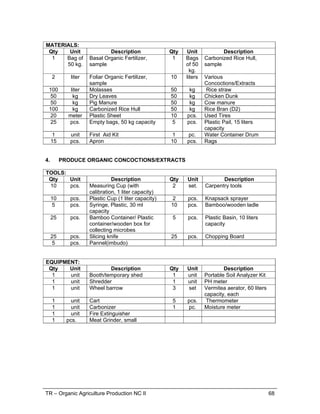

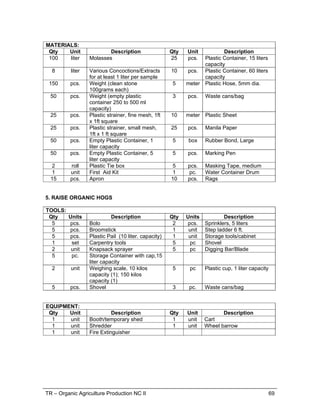

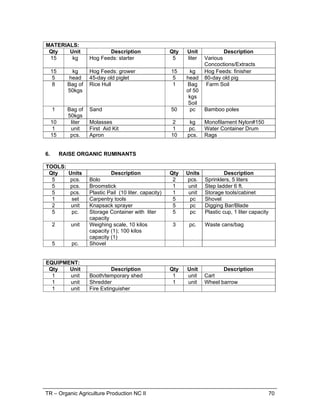

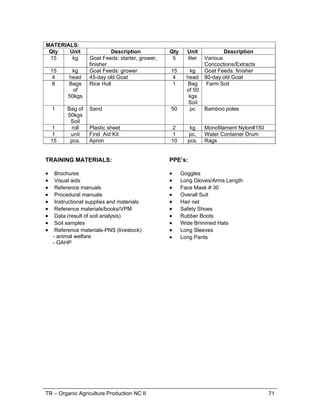

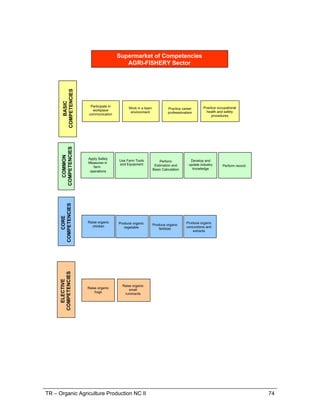

This document outlines the training regulations for the Organic Agriculture Production NC II Qualification in the Philippines. It includes 4 sections that define the qualification components, competency standards, training standards, and national assessment and certification arrangements. The qualification consists of basic, common, core and elective competencies related to organic agriculture production. The training standards section specifies the curriculum design, delivery methods, entry requirements, tools/equipment, facilities, trainer qualifications and assessment for the qualification.