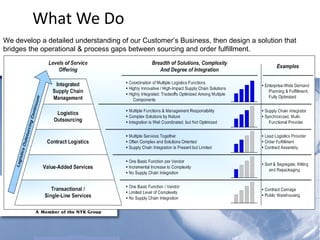

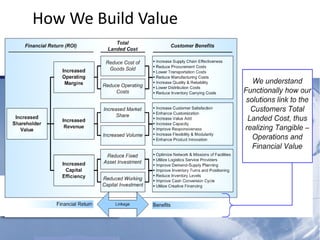

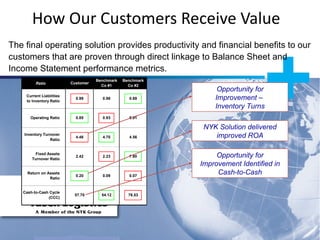

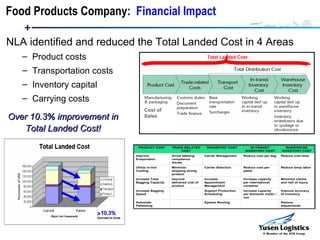

Yusen Logistics provides supply chain solutions by designing customized solutions to bridge operational and process gaps between sourcing and order fulfillment. Their solutions improve customers' productivity and financial performance by directly linking to key metrics. For a food products company customer, they conducted a supply chain evaluation that identified opportunities to reduce total landed costs by over 10% through optimizing inventory planning, transportation networks, and distribution centers.

![Allen Bains Manager, Business Development (805)460-6203 office (206)793-9166 cell [email_address]](https://image.slidesharecdn.com/scsoverview-casestudy-110509093637-phpapp02/85/Total-Landed-Cost-Case-Study-9-320.jpg)