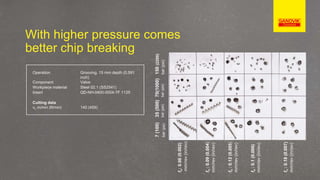

The document provides tips for successful parting and grooving operations. It recommends using tools with over- and under-coolant to control chips, wear, and temperature. Quick change systems and smart clamping solutions can minimize tool change time and avoid errors. When parting off, reduce feed rate near the part falling off, maintain center height tolerance, and turn off coolant at the rpm limit. For face grooving, start on the largest diameter and work inward in multiple cuts, use side turning when possible, and use the highest coolant pressure to improve chip control and evacuation.