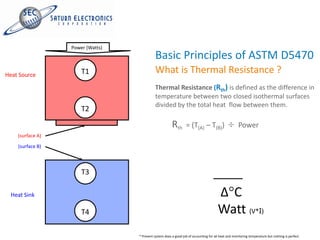

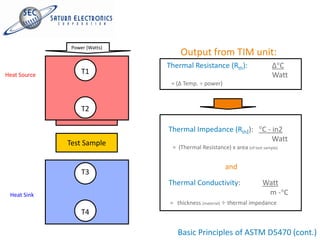

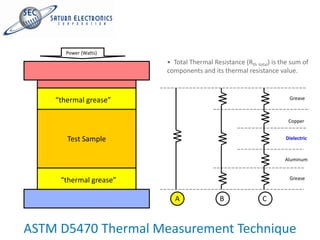

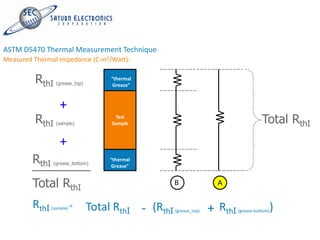

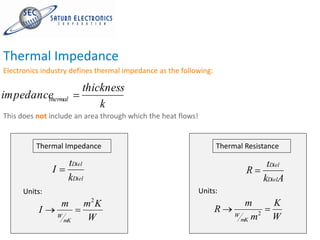

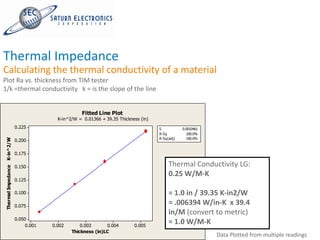

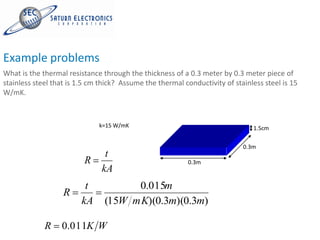

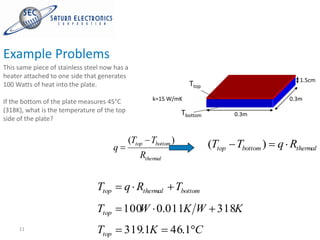

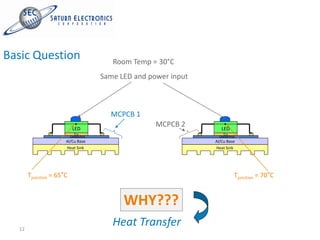

The document discusses thermal transfer principles, focusing on thermal impedance, resistance, and conductivity metrics such as °C in²/W and °W/m-K. It emphasizes the advantages of using Kapton®/polyimide materials in thermal management through low thermal impedance and high reliability, while also detailing the measurement techniques outlined in ASTM D5470 for evaluating material performance. Additionally, it provides examples and calculations related to thermal resistance and conductivity in various materials and situations.