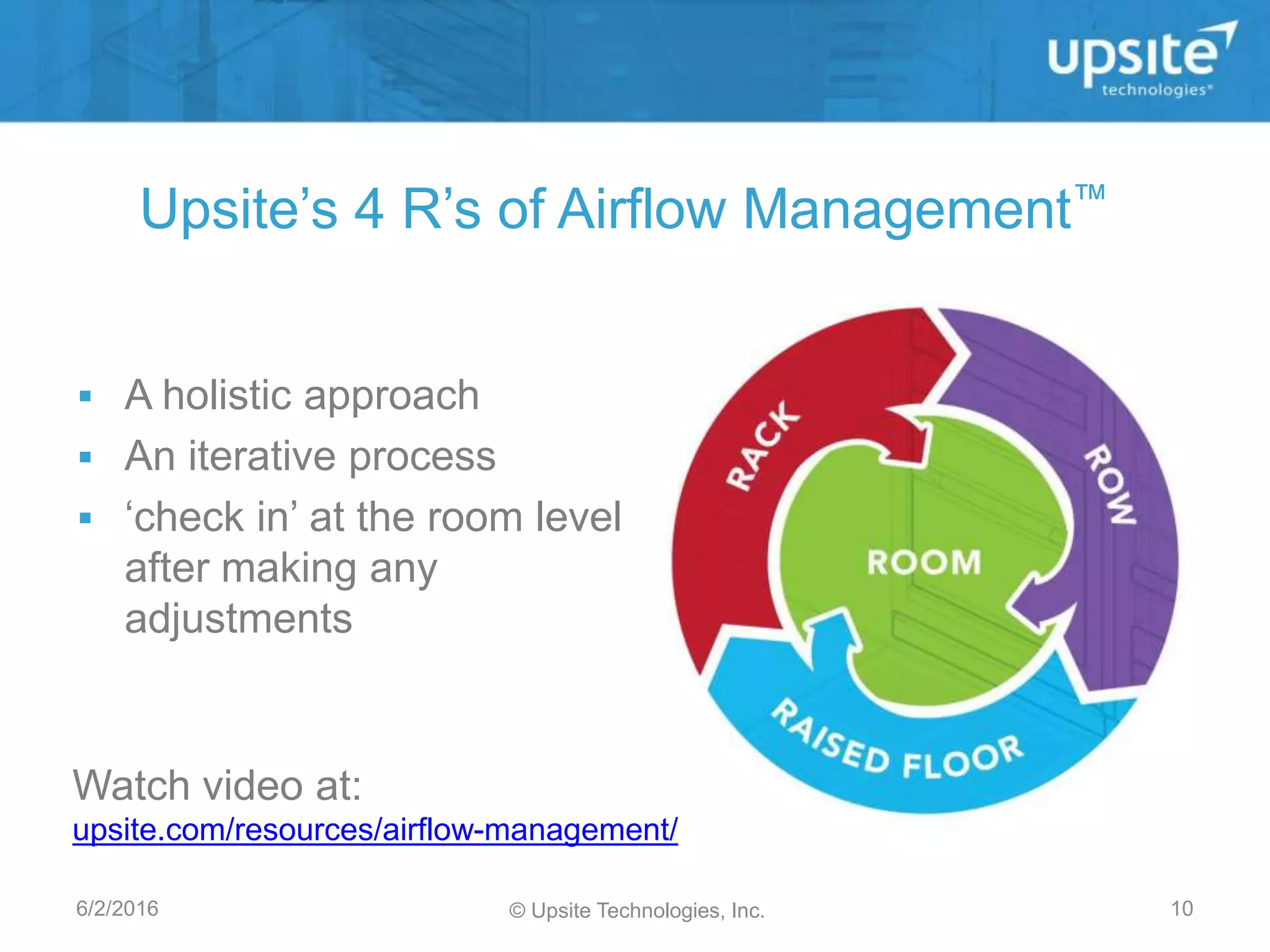

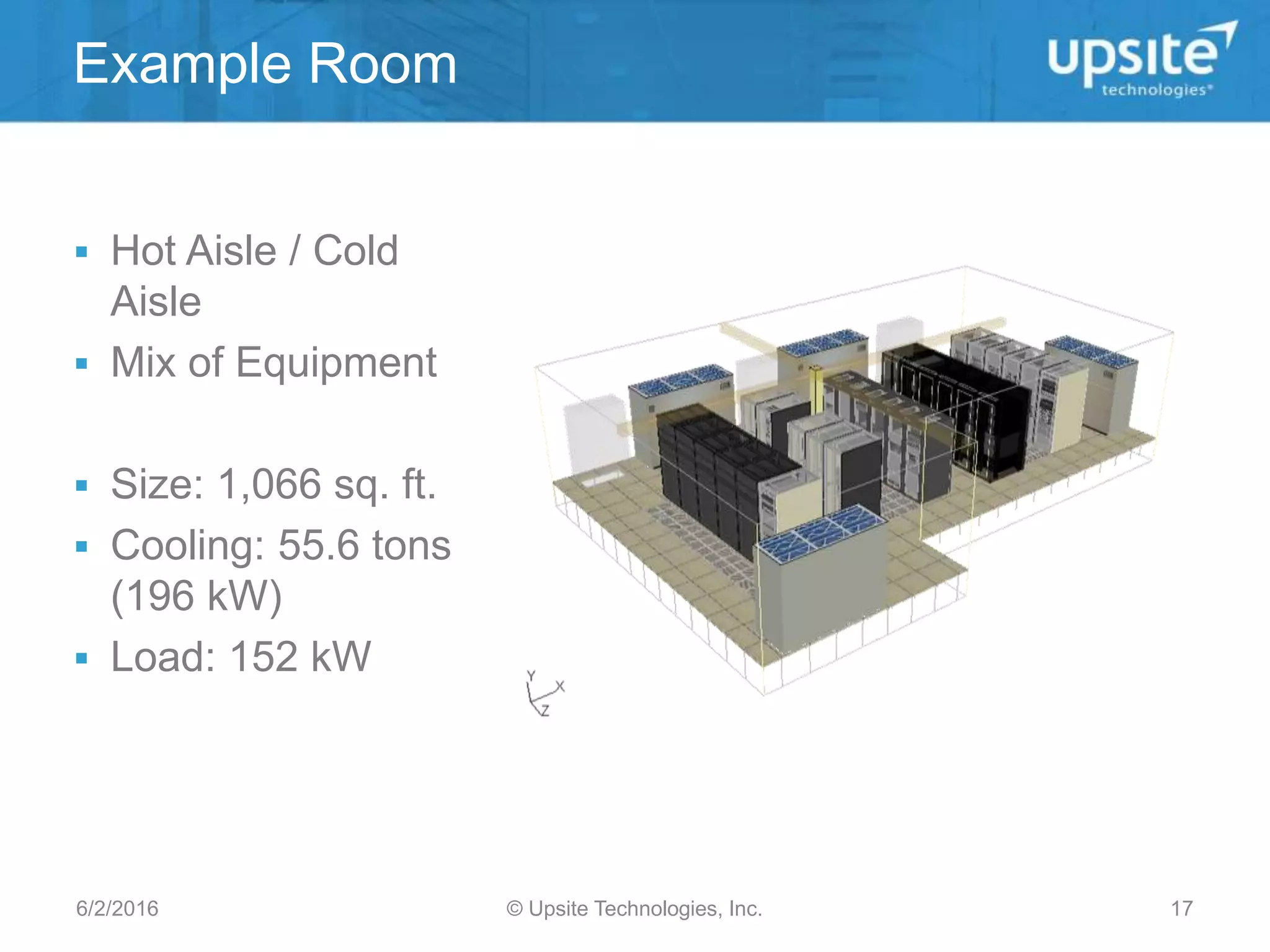

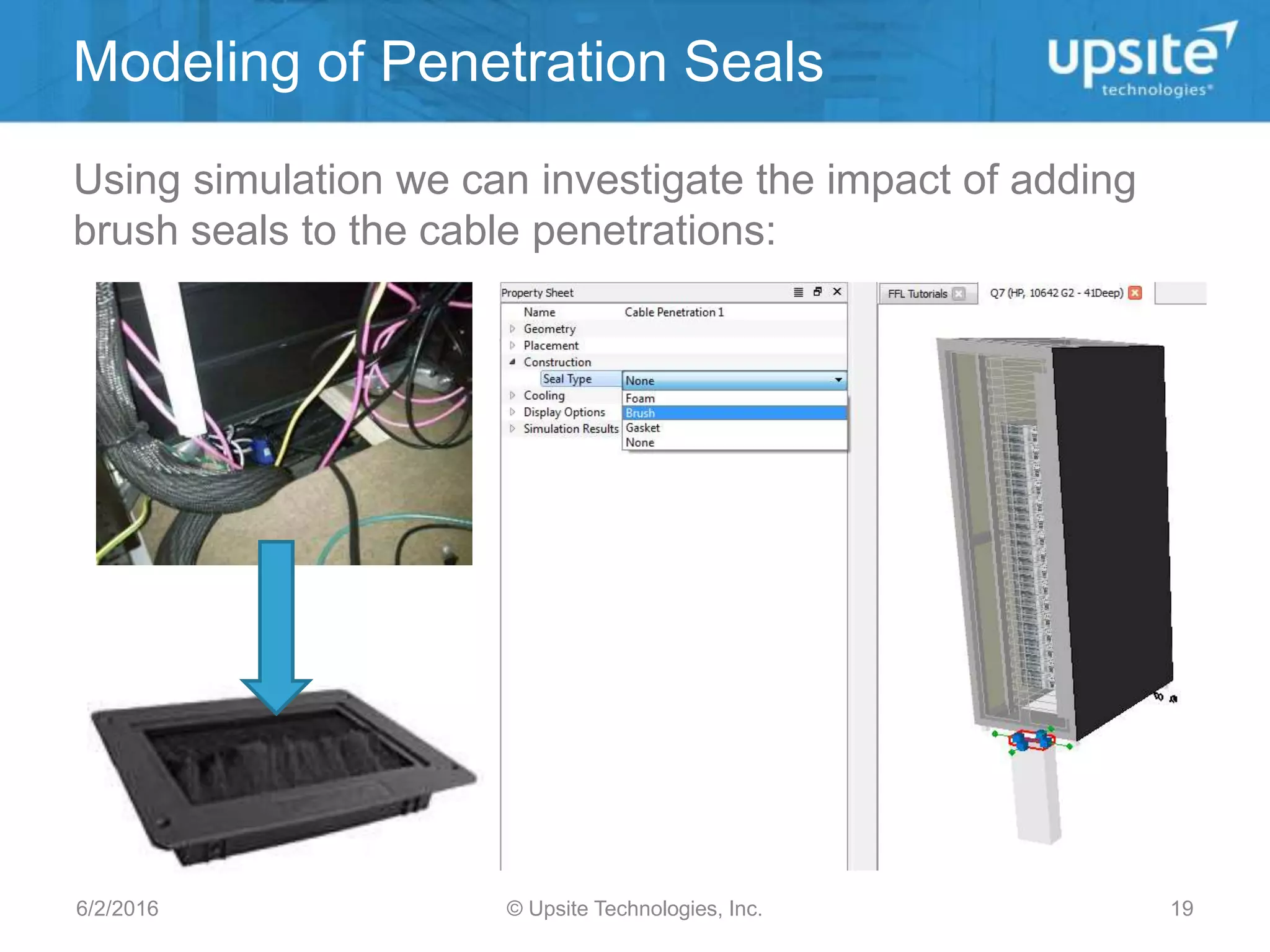

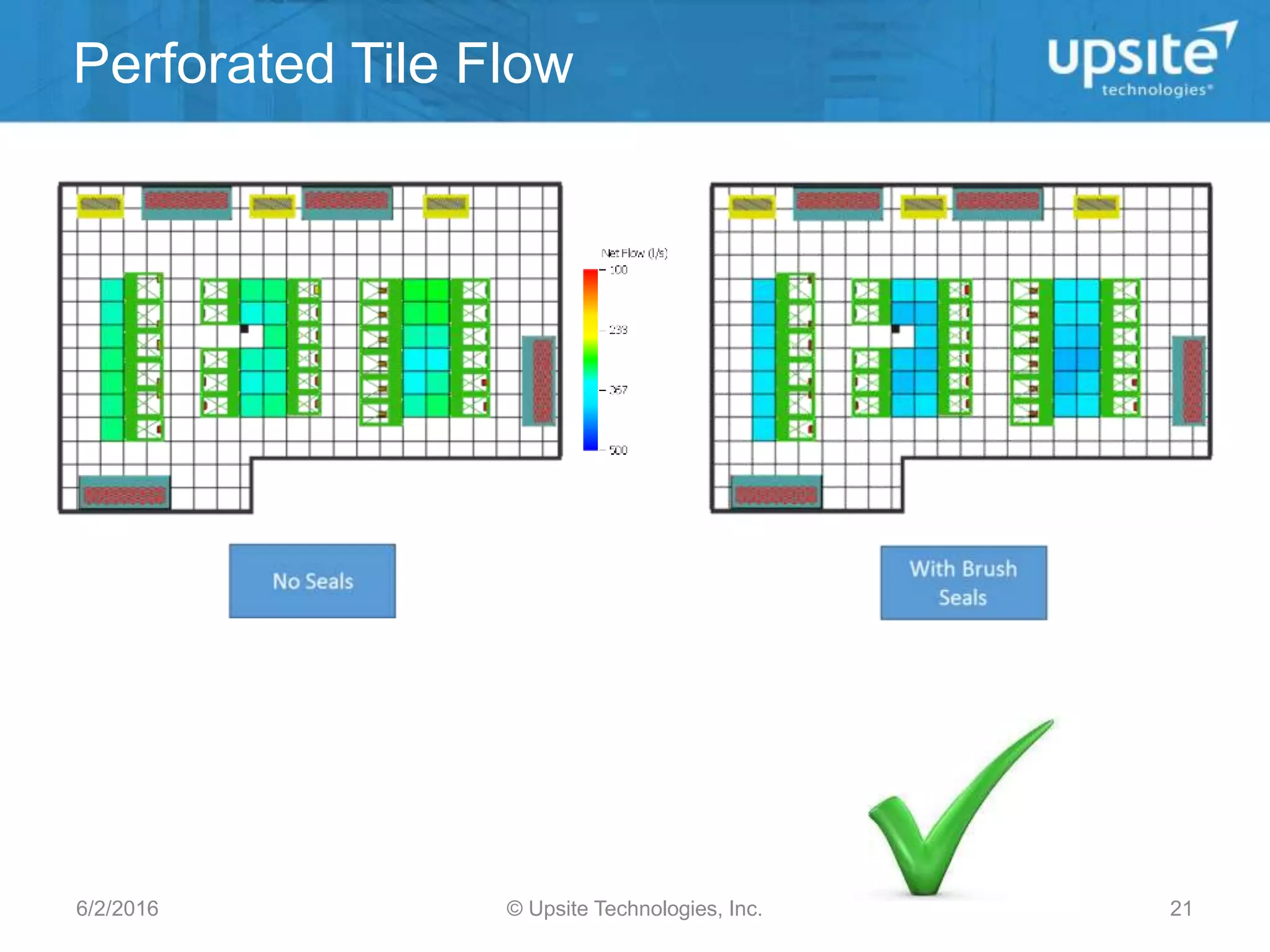

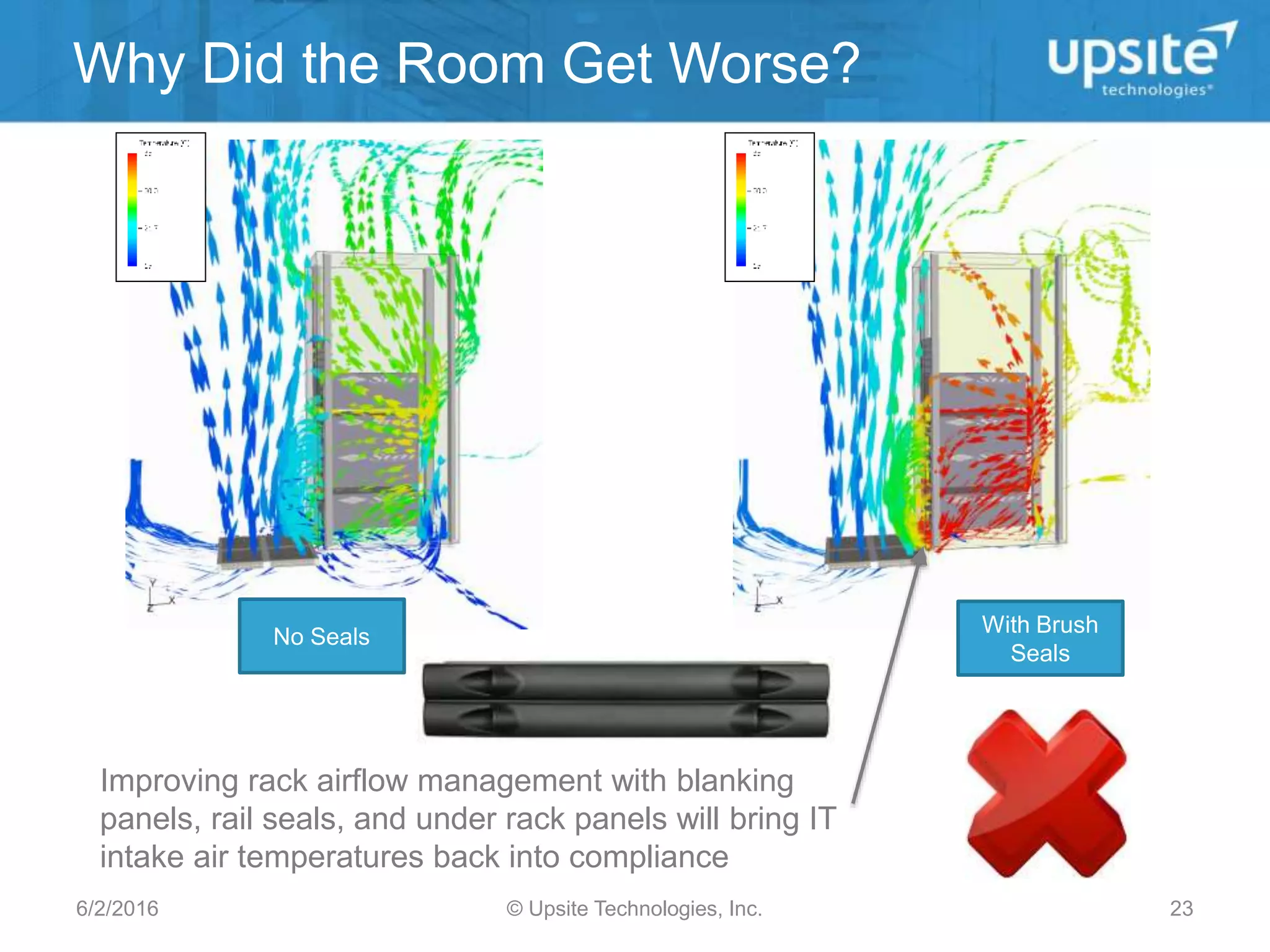

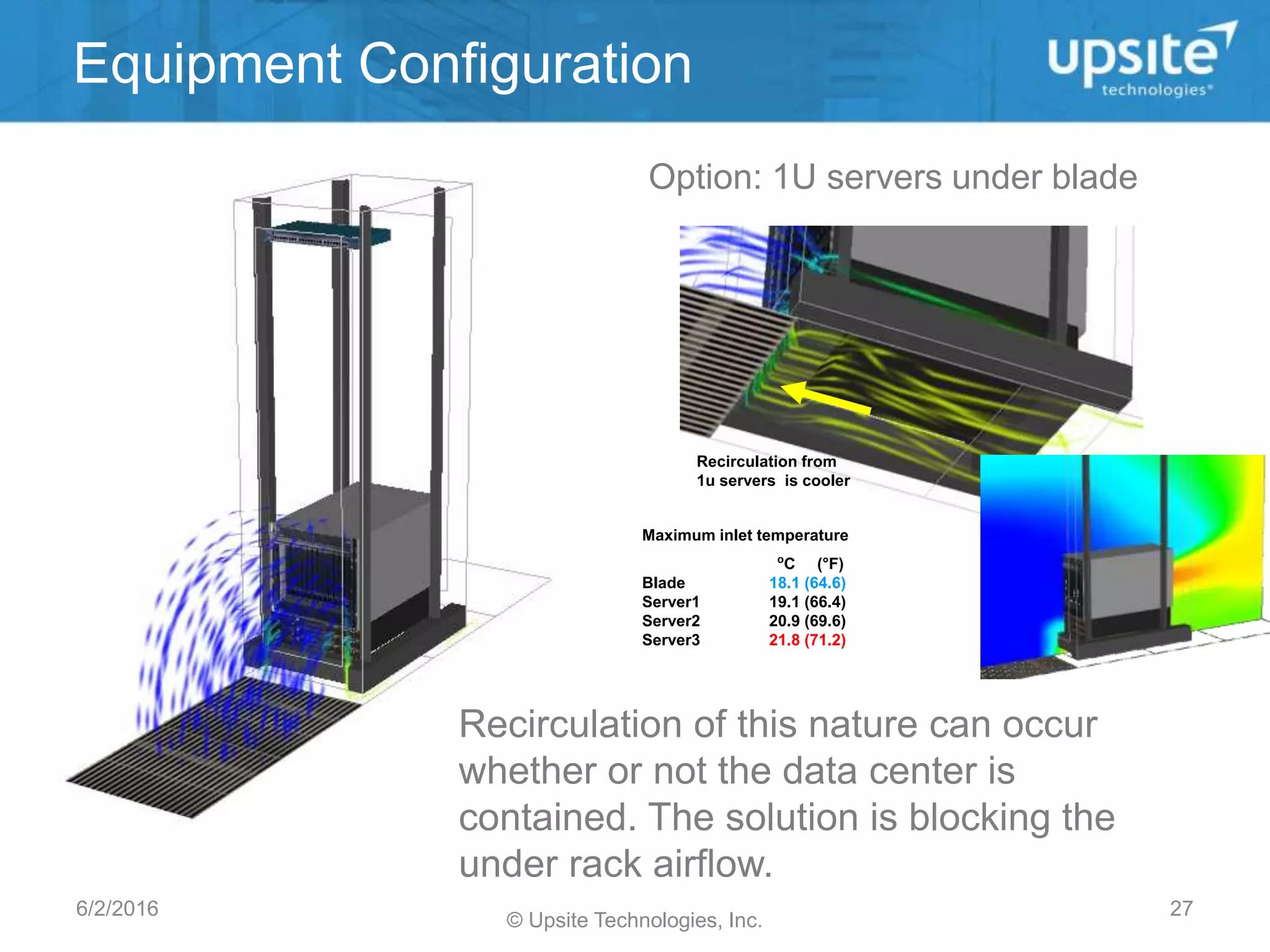

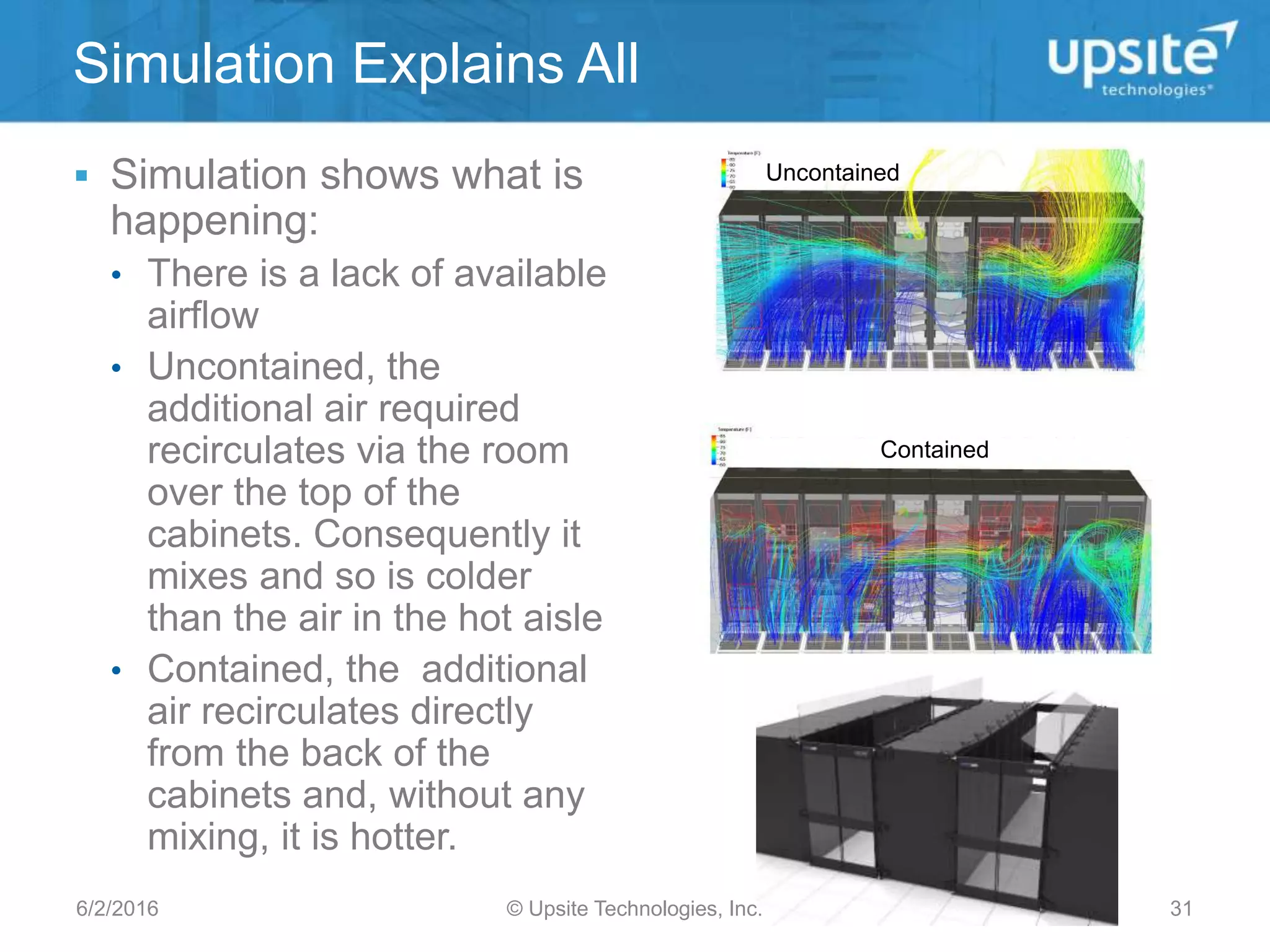

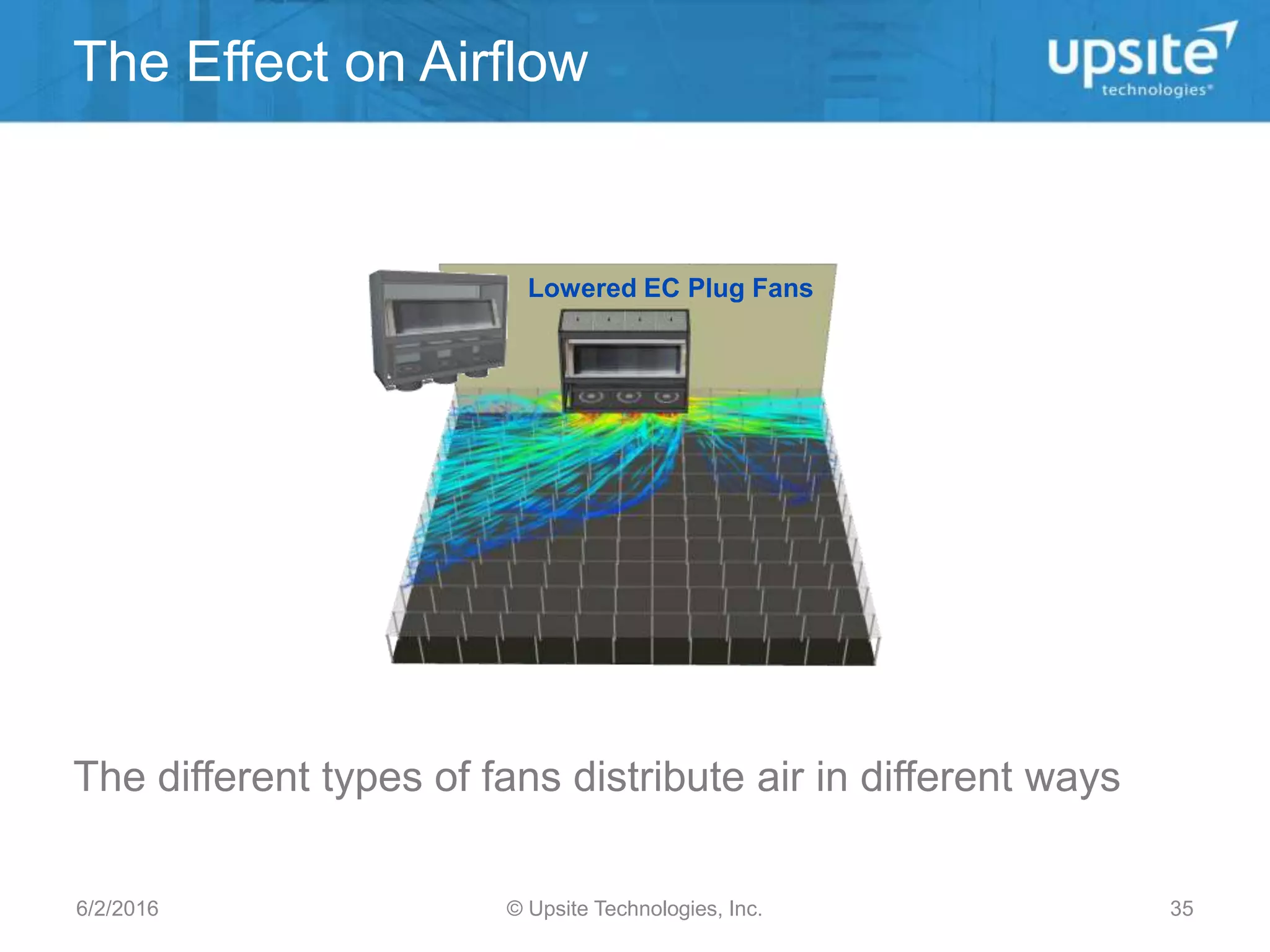

The document discusses best practices for airflow management in computer rooms and data centers. It identifies two types of computer rooms - those without and with intake air temperature problems for IT equipment. Improving airflow management (AFM) can solve intake air issues to make facilities more efficient. The document also discusses concepts like bypass airflow, recirculation, and the benefits of proper cable penetrations and containment. It provides examples of how AFM practices applied incorrectly can negatively impact cooling and presents strategies like Upsite's 4 R's methodology to optimize airflow.