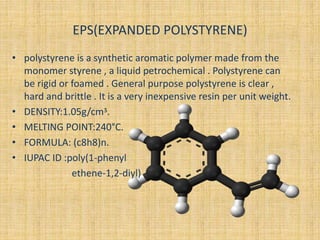

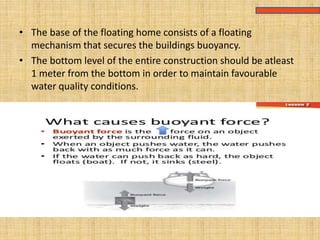

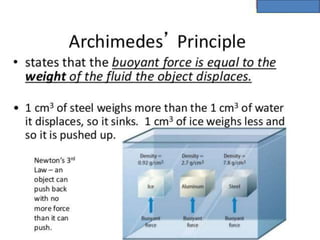

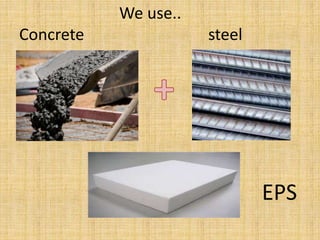

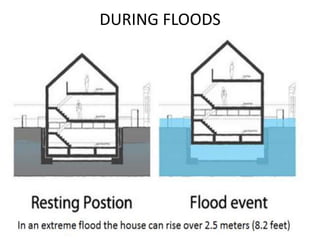

The document discusses the design and environmental benefits of an amphibious structure using expanded polystyrene (EPS) as a key material, which provides buoyancy and flood resistance. It highlights EPS's properties, applications in construction, and its minimal environmental impact, such as low thermal conductivity and reduced waste. The proposed floating homes aim to create sustainable, economical housing solutions that adapt to water level changes while ensuring safety during floods.