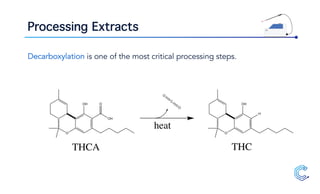

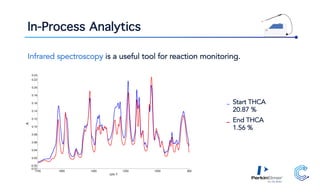

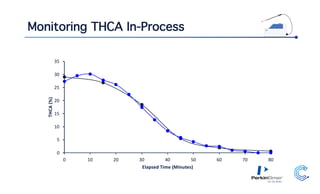

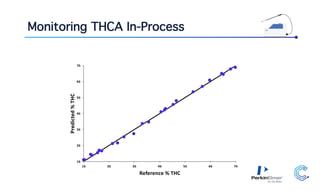

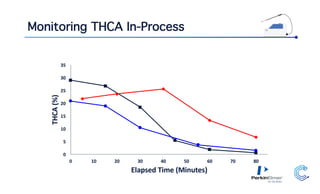

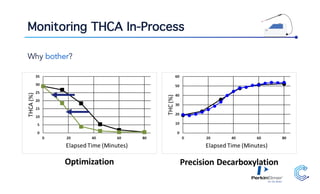

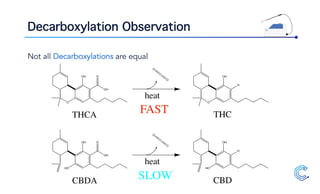

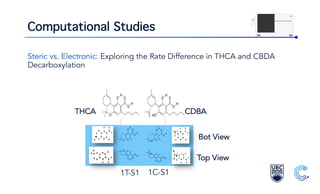

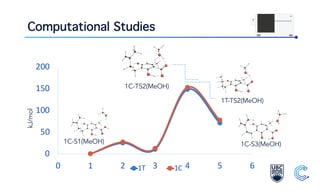

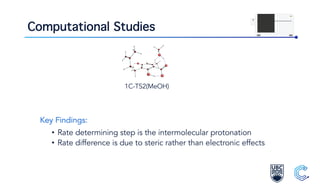

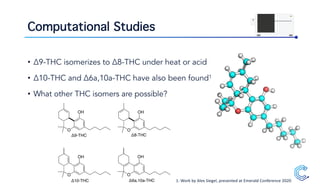

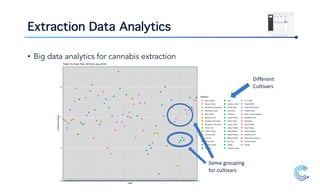

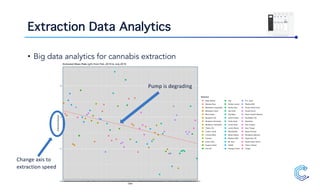

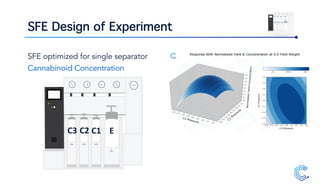

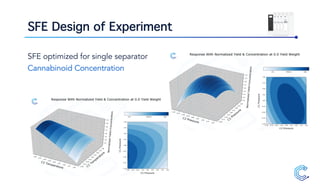

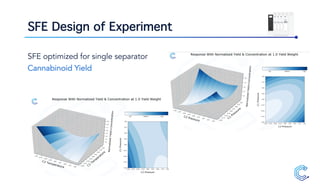

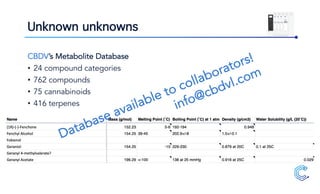

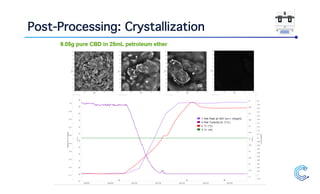

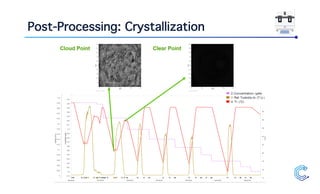

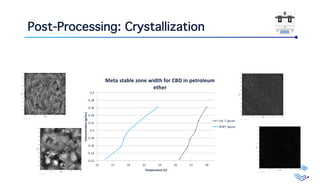

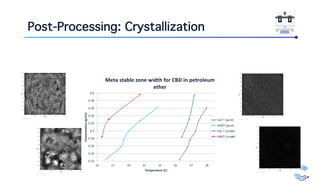

Dr. Markus Roggen founded Complex Biotech Discovery Ventures (CBDV) to establish a research hub focused on fundamental scientific insights into cannabis production processes like decarboxylation and crystallization through collaborative projects with academic and industry partners utilizing analytical techniques like infrared spectroscopy and computational studies. CBDV seeks to optimize cannabis processing through in-line monitoring, design of experiments, data analytics, and developing a metabolite database to support the industry.