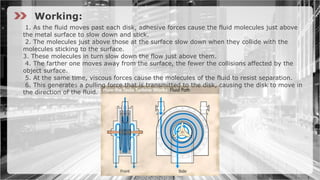

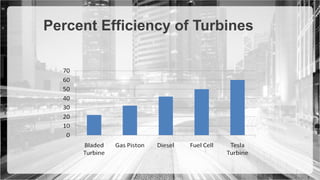

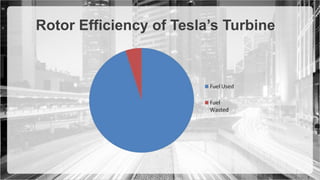

The Tesla turbine, patented by Nikola Tesla in 1913, is a bladeless centripetal flow turbine that leverages the boundary layer effect for energy conversion, achieving up to 95% efficiency with steam. It is simple to construct using readily available materials and can also function as a pump with a minor modification. Despite its potential advantages and being established in some applications, widespread commercial use remains limited due to insufficient contracts and further research needs.

![SRIDHAR.P [17Q91A0334]

Mechanical Engineering

Malla Reddy College of Engineering

TOPIC:

TESLA TURBINE](https://image.slidesharecdn.com/teslapptfinal-210222141255/85/Tesla-Turbine-PPT-1-320.jpg)