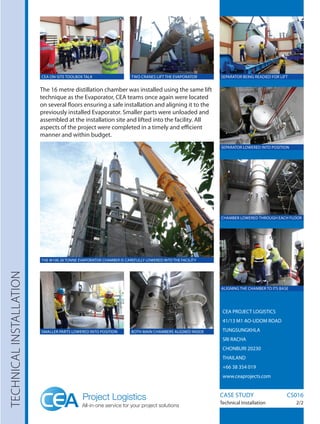

The document outlines a successful technical installation project completed by CEA for a drinks manufacturer in Chachoengsao, Thailand, lasting three days and involving the transport and installation of large equipment including evaporators and distillation chambers. The project required precise logistics, including the use of mobile cranes for safely lifting heavy parts into the facility. All work was carried out efficiently, on time, and within budget.