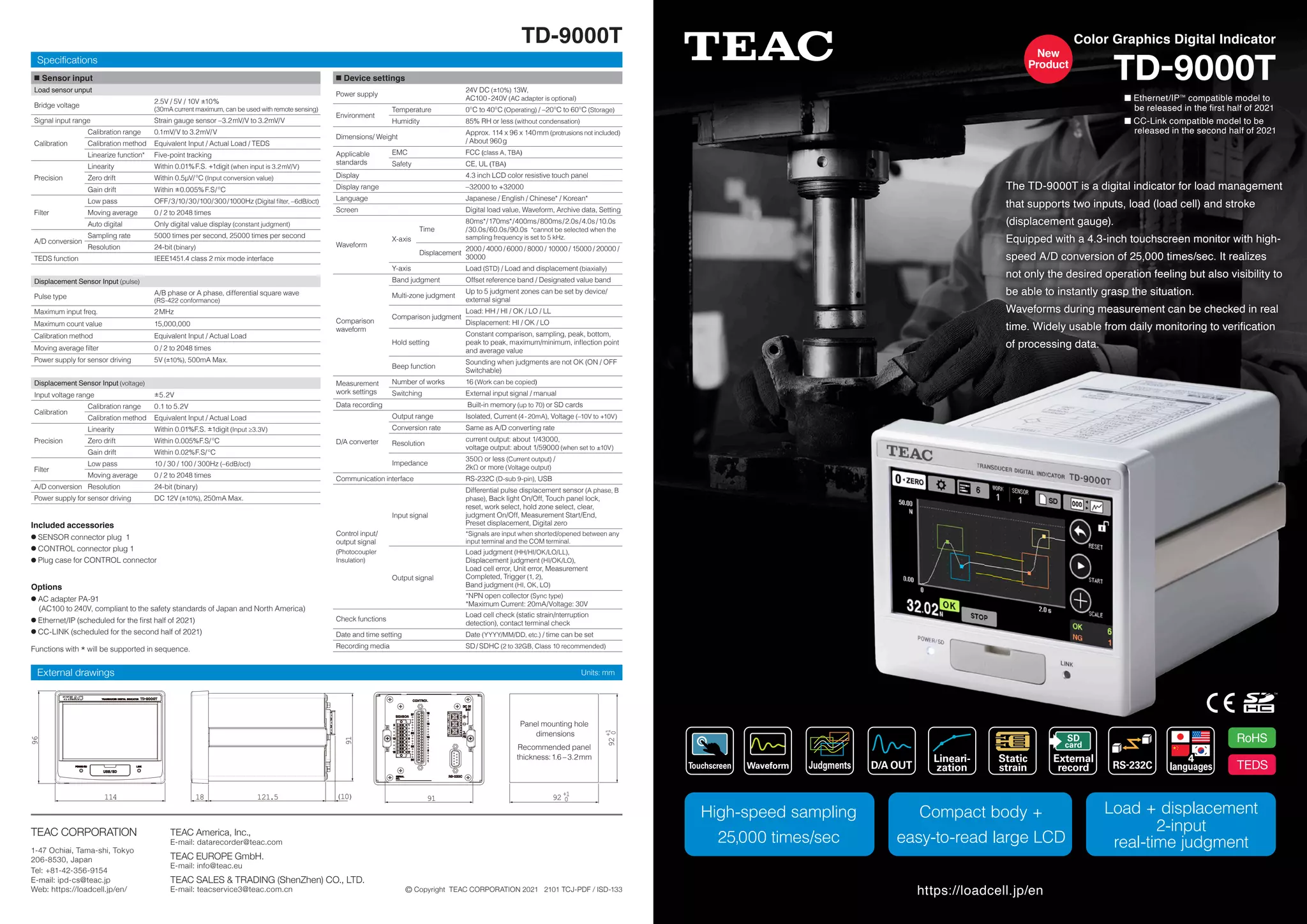

The TD-9000T is a digital indicator designed for load management, equipped with a 4.3-inch touchscreen and capable of handling two inputs - load and stroke. It offers high-speed A/D conversion and real-time waveform monitoring, making it suitable for various applications from daily monitoring to data verification. The device is expected to support Ethernet/IP and CC-Link options, enhancing its connectivity for broader system integration.