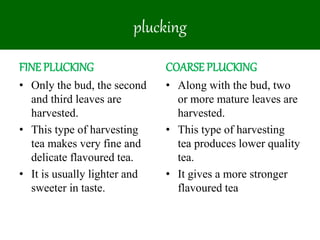

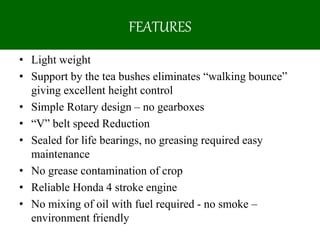

India and China are the largest producers and consumers of tea. Tea leaves are ready for harvesting after 5 years. Manual harvesting involves plucking only the buds and youngest leaves by hand. An experienced worker can harvest 40kg per day. Mechanized harvesting was introduced due to labor shortages and increasing wages, and can harvest over 1000kg in 8 hours. There are two main types of tea leaf harvesters - petrol/gas powered machines that harvest 900kg per day but produce fumes and noise, and battery powered machines that are quieter but can damage leaves and harvest only 30kg per hour. Selective harvesting machines harvest more efficiently while minimizing damage to tea bushes.