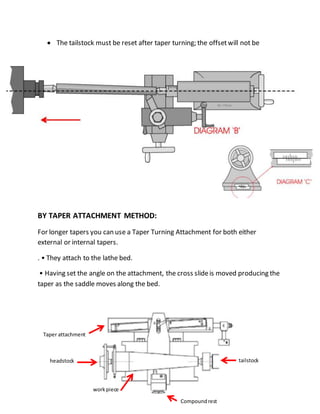

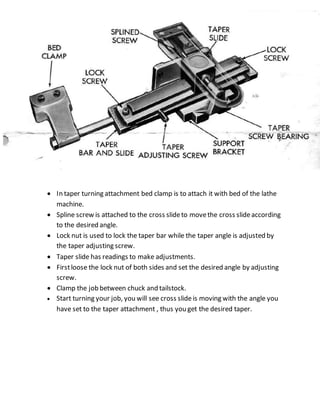

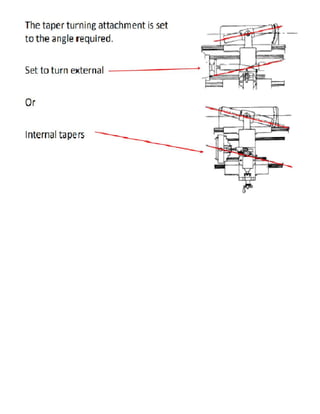

This manual discusses two methods for forming tapers on workpieces in a lathe: offsetting the tailstock and using a taper attachment. Offsetting the tailstock involves calculating the distance to offset the tailstock from the centerline and clamping the workpiece between the chuck and offset tailstock to cut a taper. The taper attachment method uses an attachment that mounts to the lathe bed and allows adjusting the angle to move the cross-slide and cut a taper as the workpiece moves along the bed. Both methods involve clamping the workpiece and adjusting settings to cut the desired taper angle on the lathe.