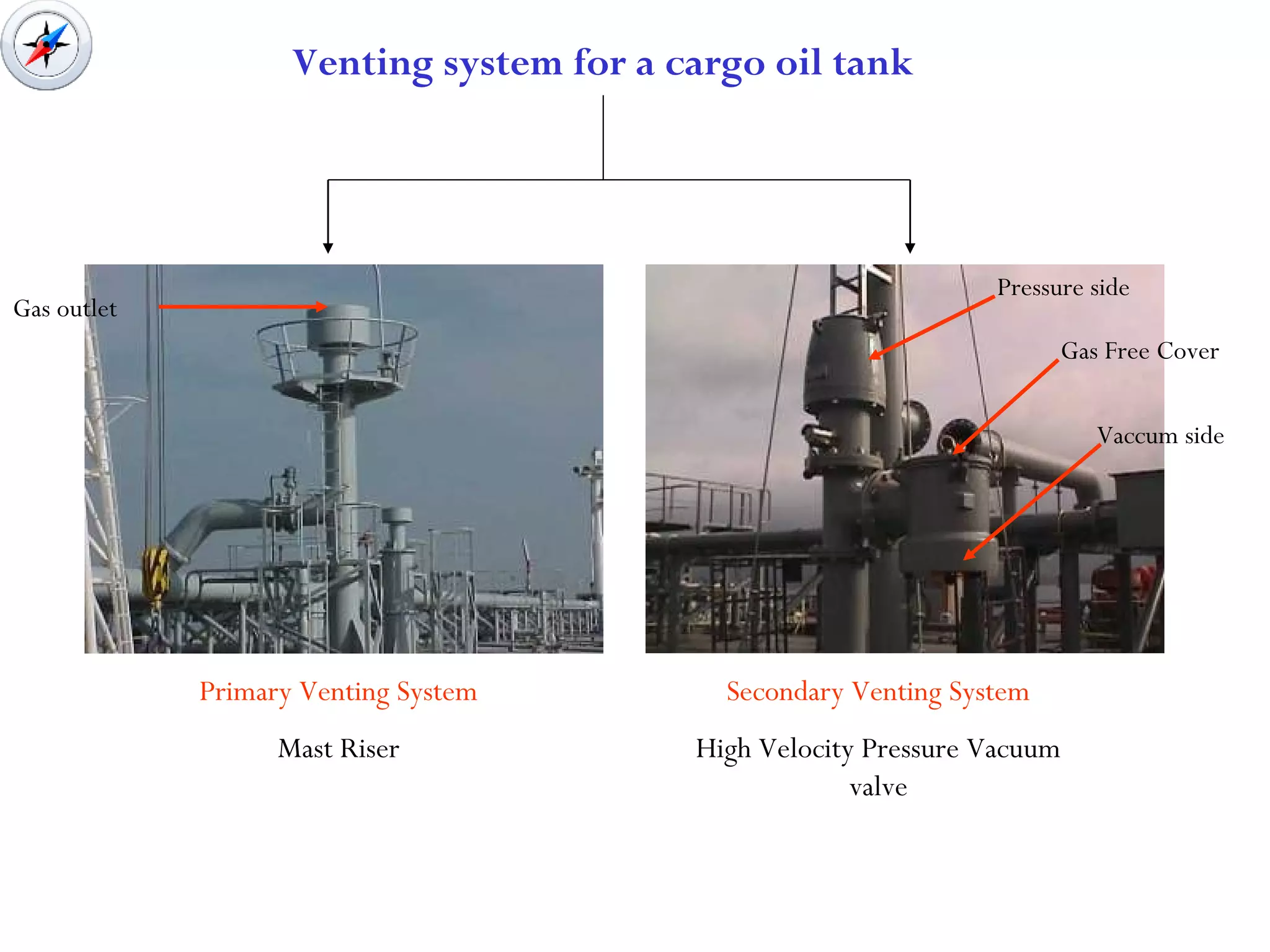

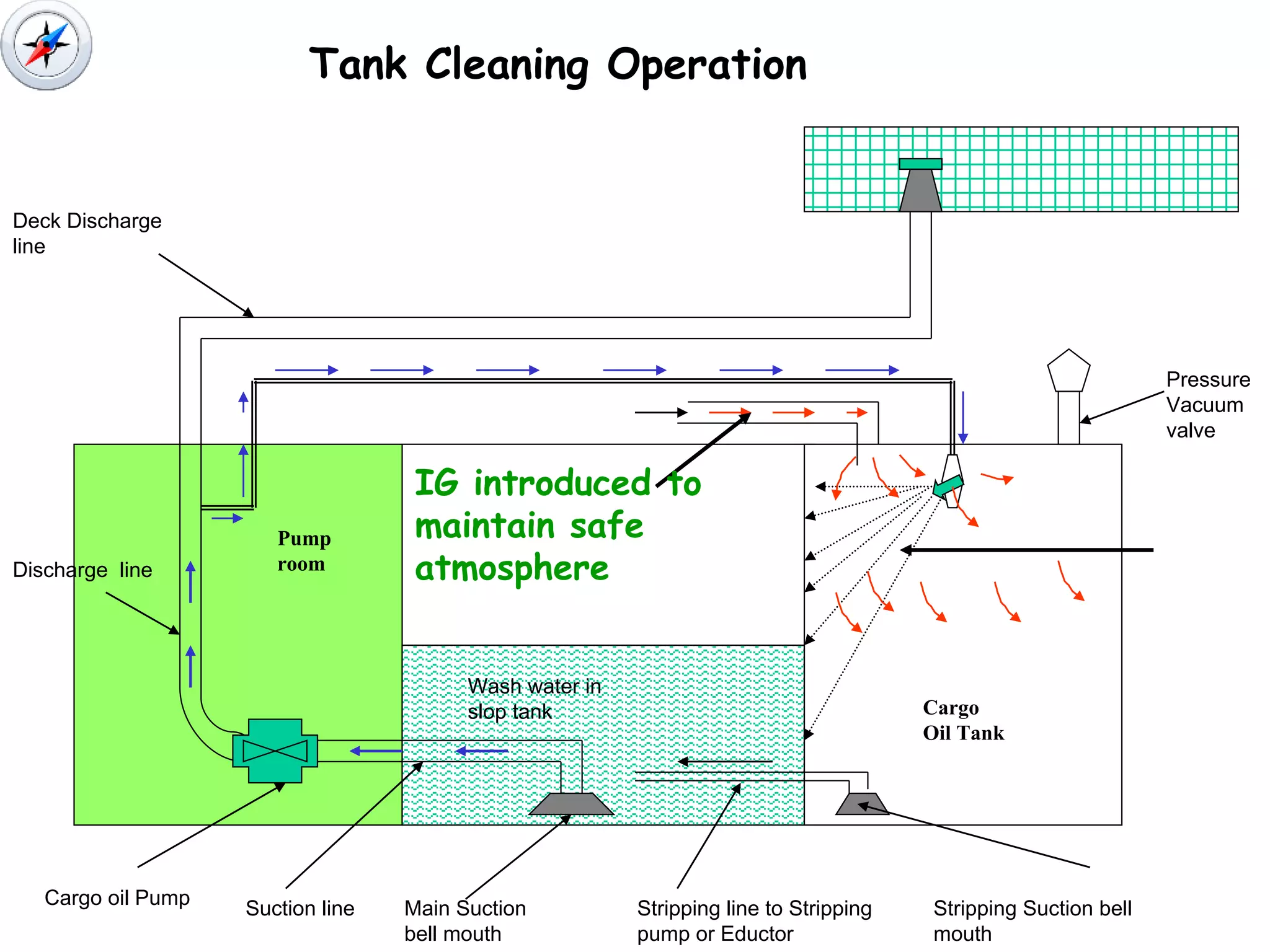

This document discusses cargo tank atmospheres on oil and chemical tankers. It notes that cargo tanks are enclosed spaces that can accumulate dangerous gases if not properly ventilated. The main hazards associated with tank atmospheres are fires and health issues caused by oxygen depletion, toxic gases, or flammable vapors. Inert gas systems are used to control tank atmospheres and remove oxygen, preventing fires. Key operations like loading, discharging, and tank cleaning require maintaining a safe inert atmosphere through controlled introduction of inert gas to dilute tank contents. Atmosphere monitoring equipment is used to check oxygen, hydrocarbon, and toxic gas levels during operations.