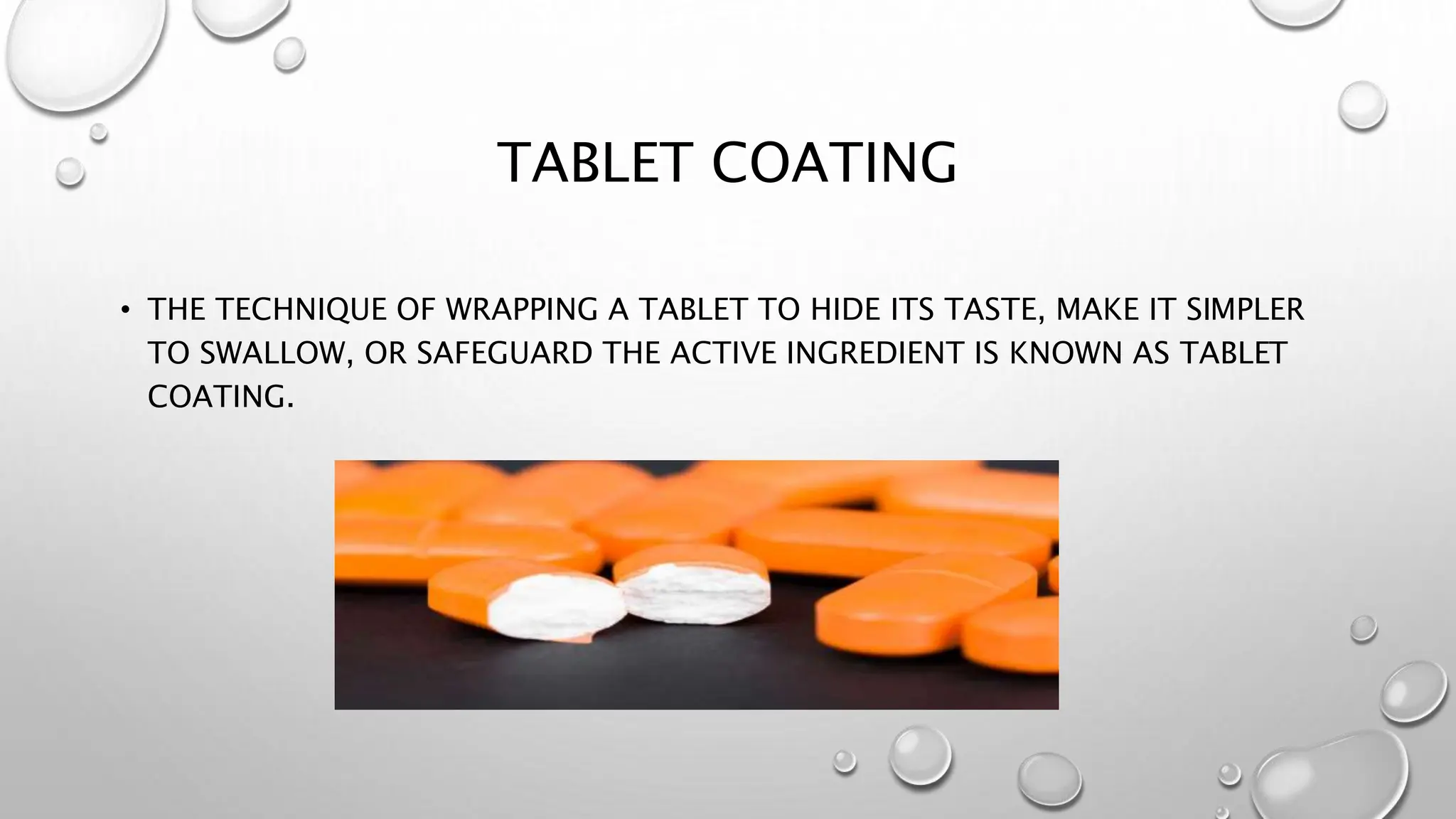

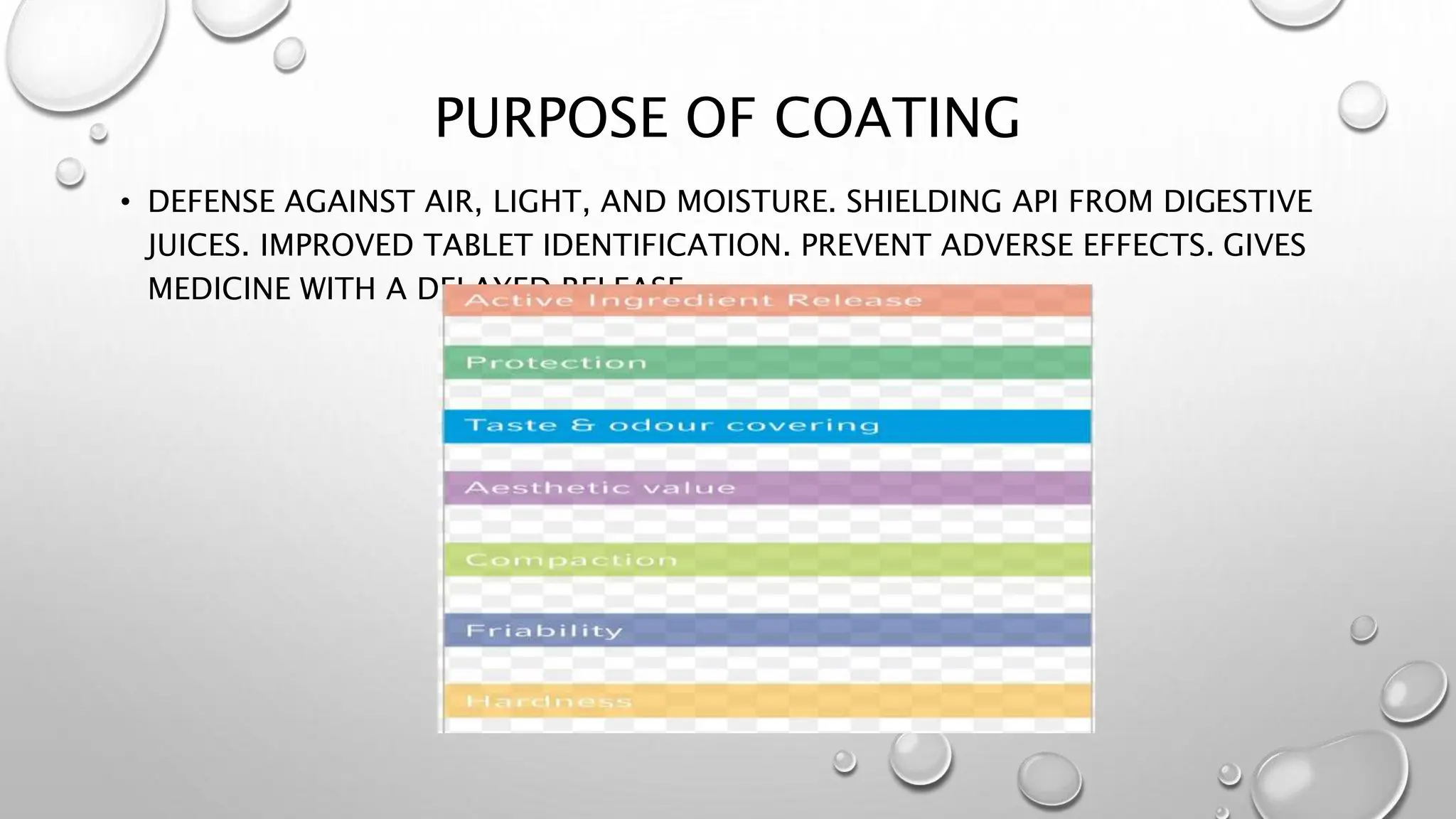

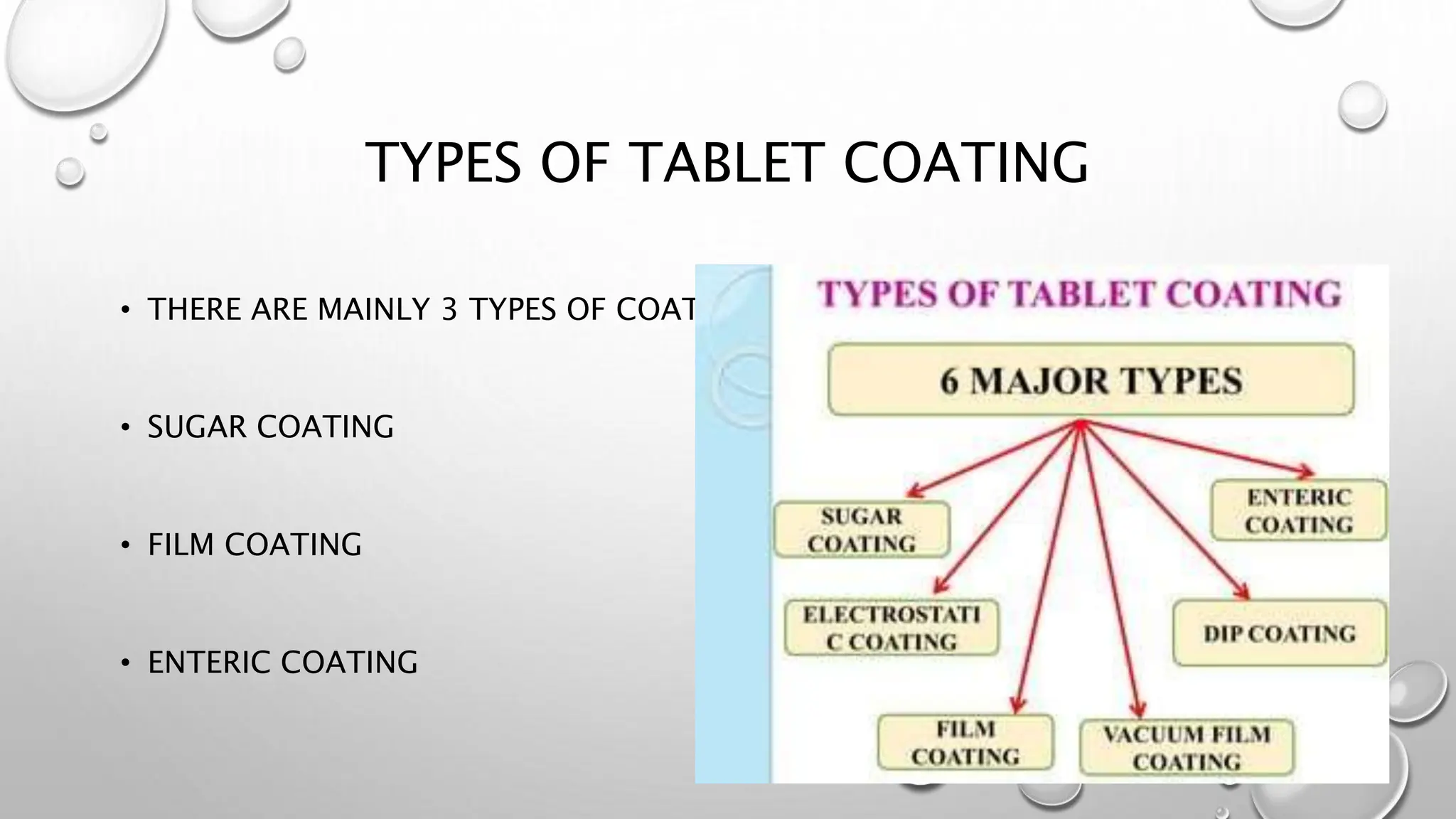

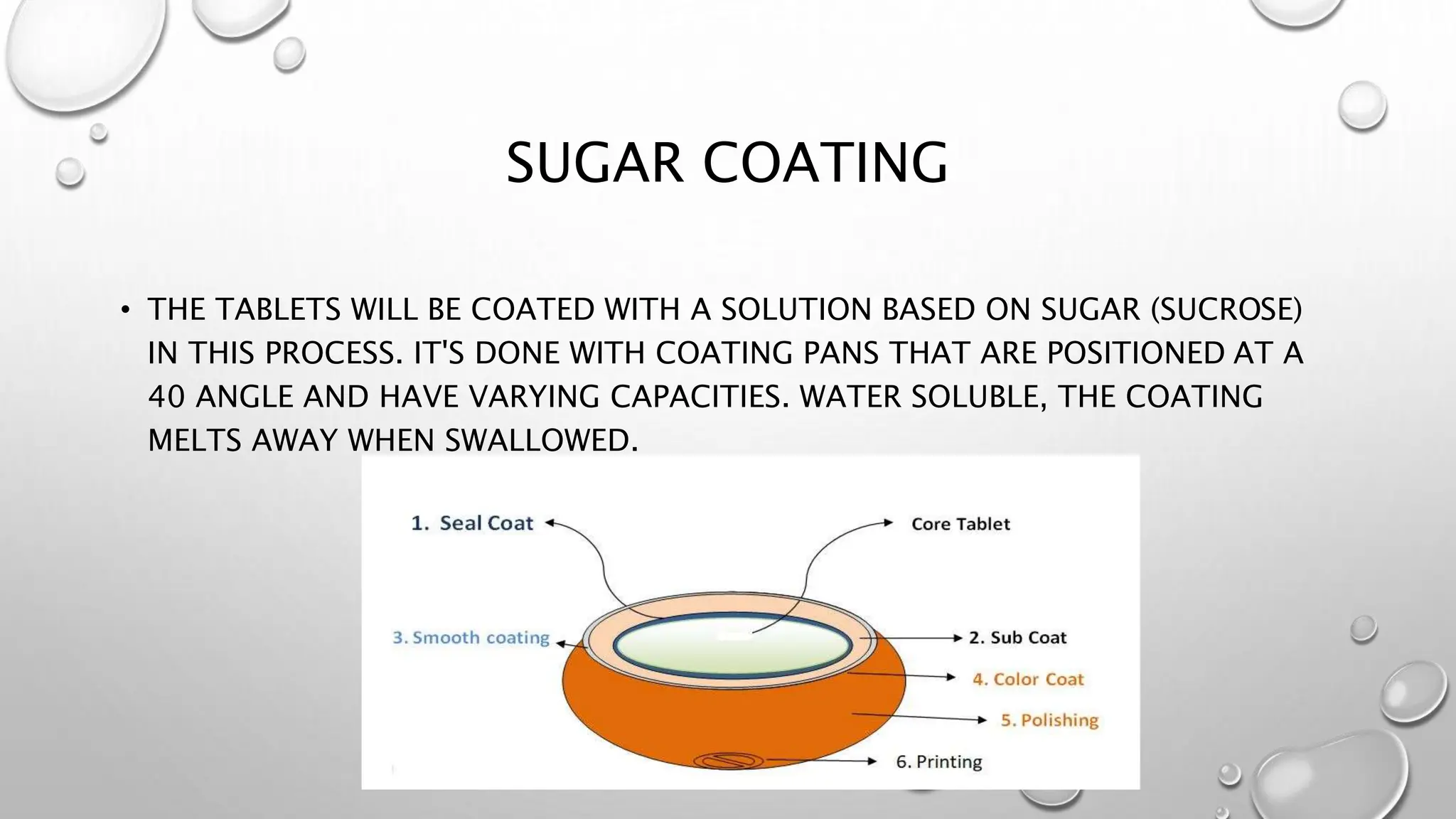

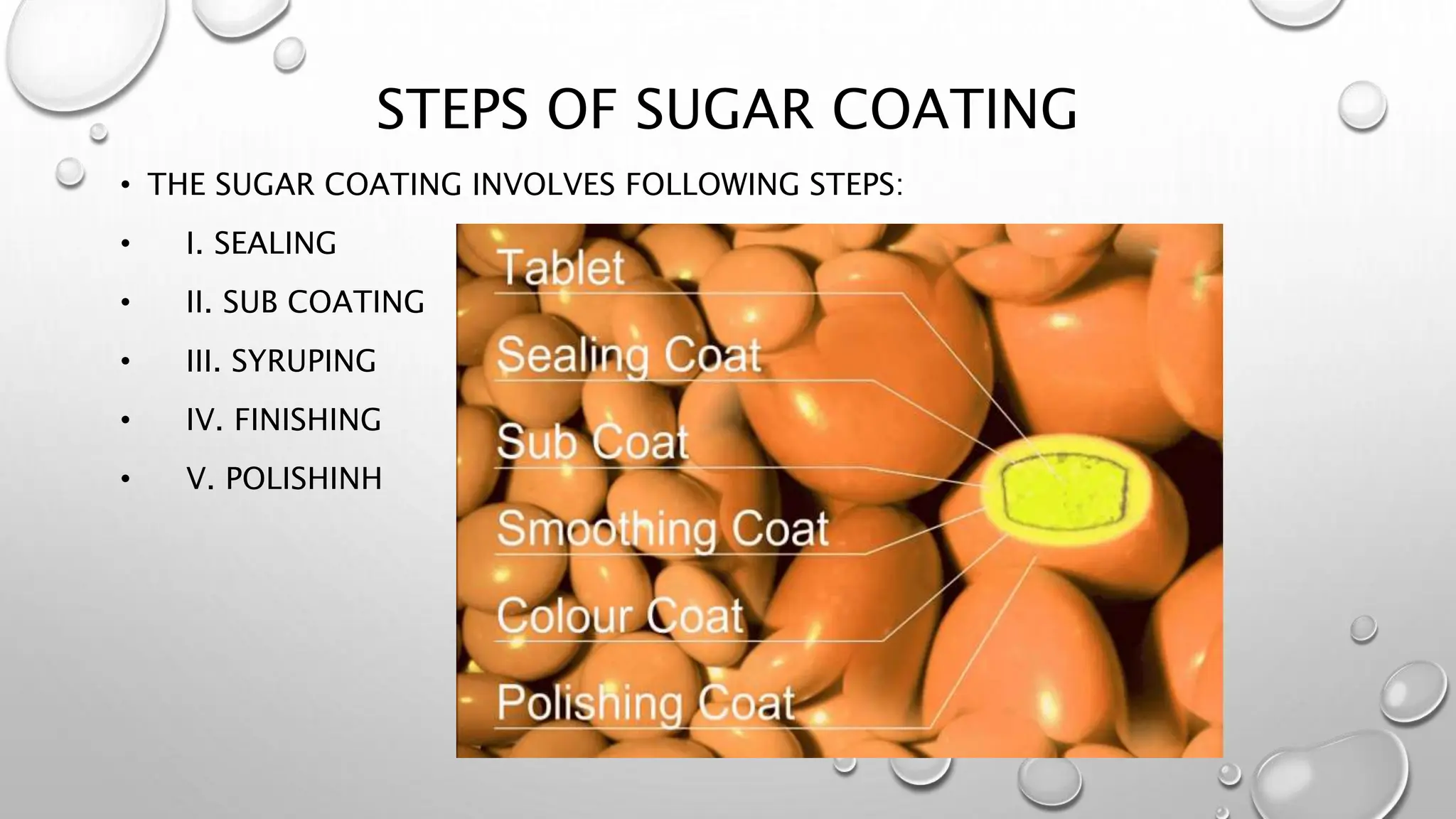

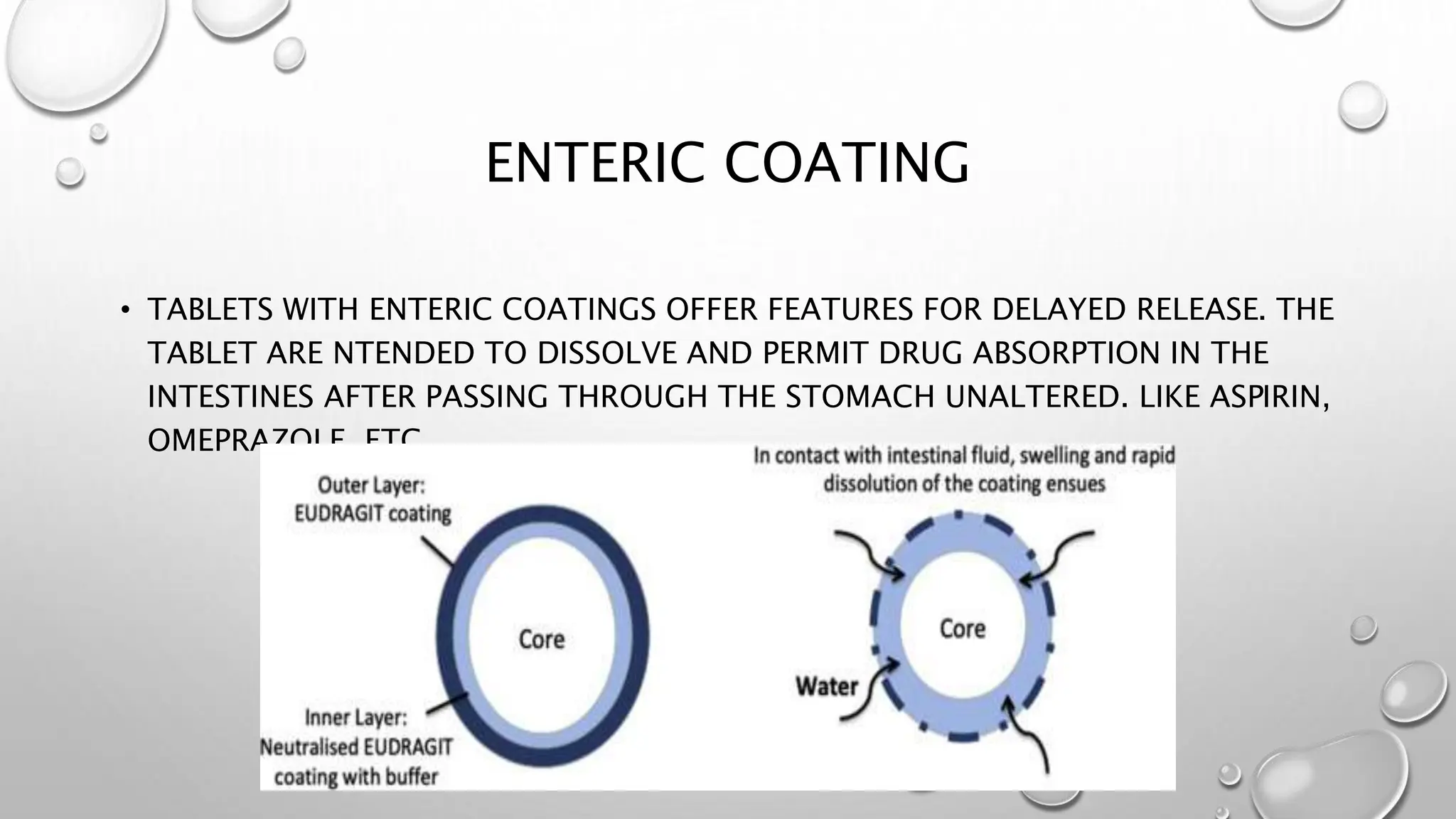

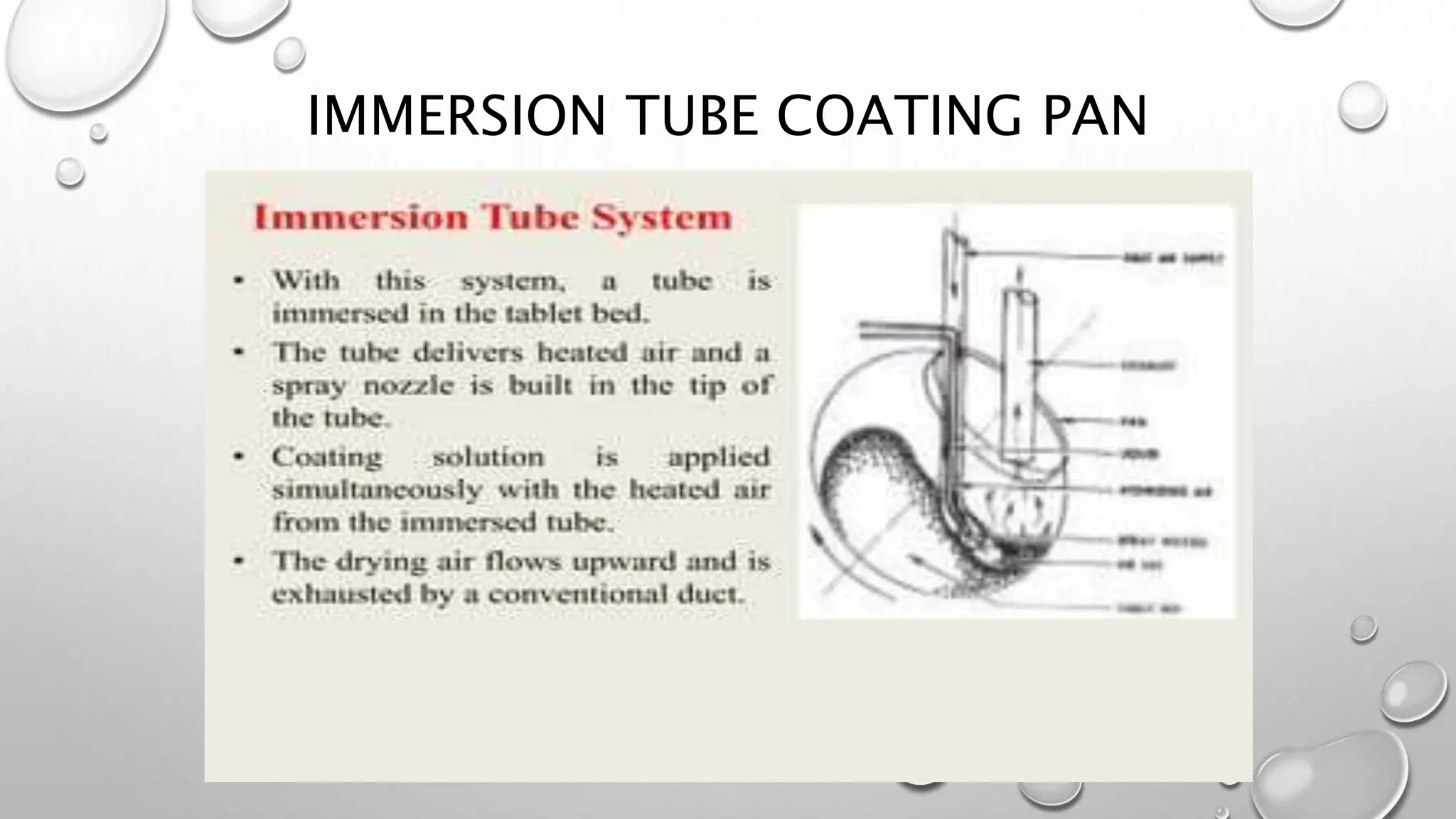

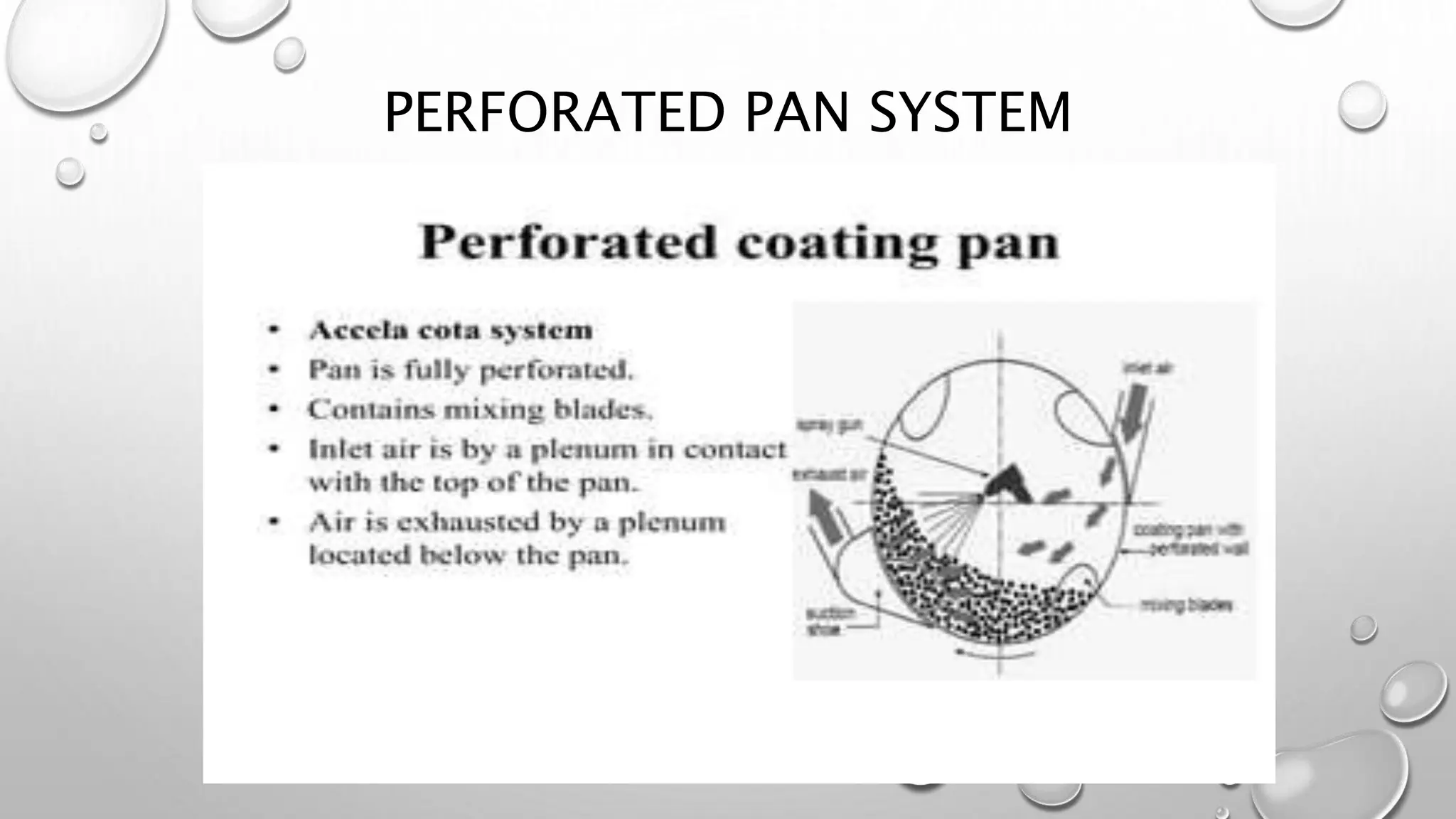

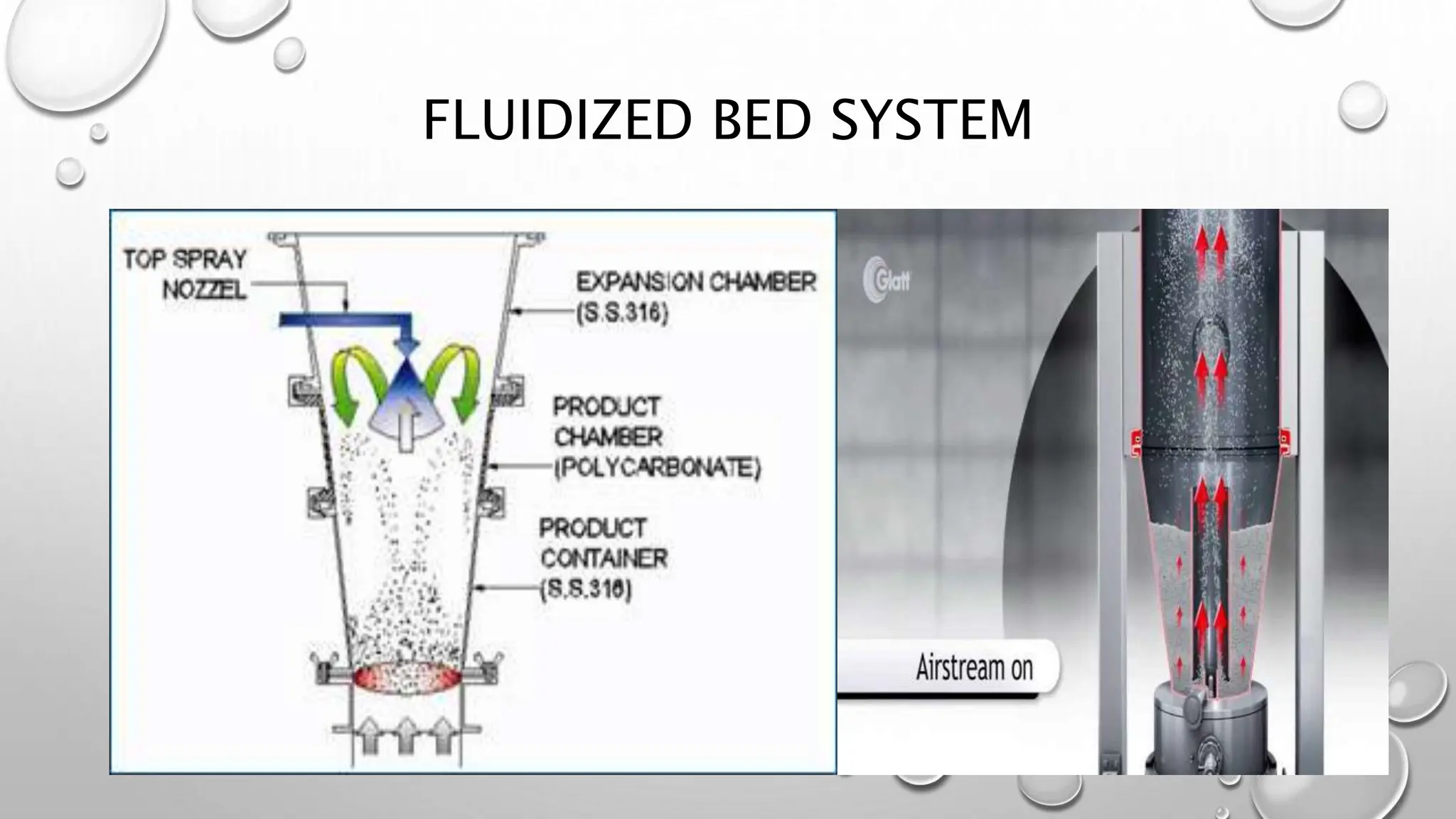

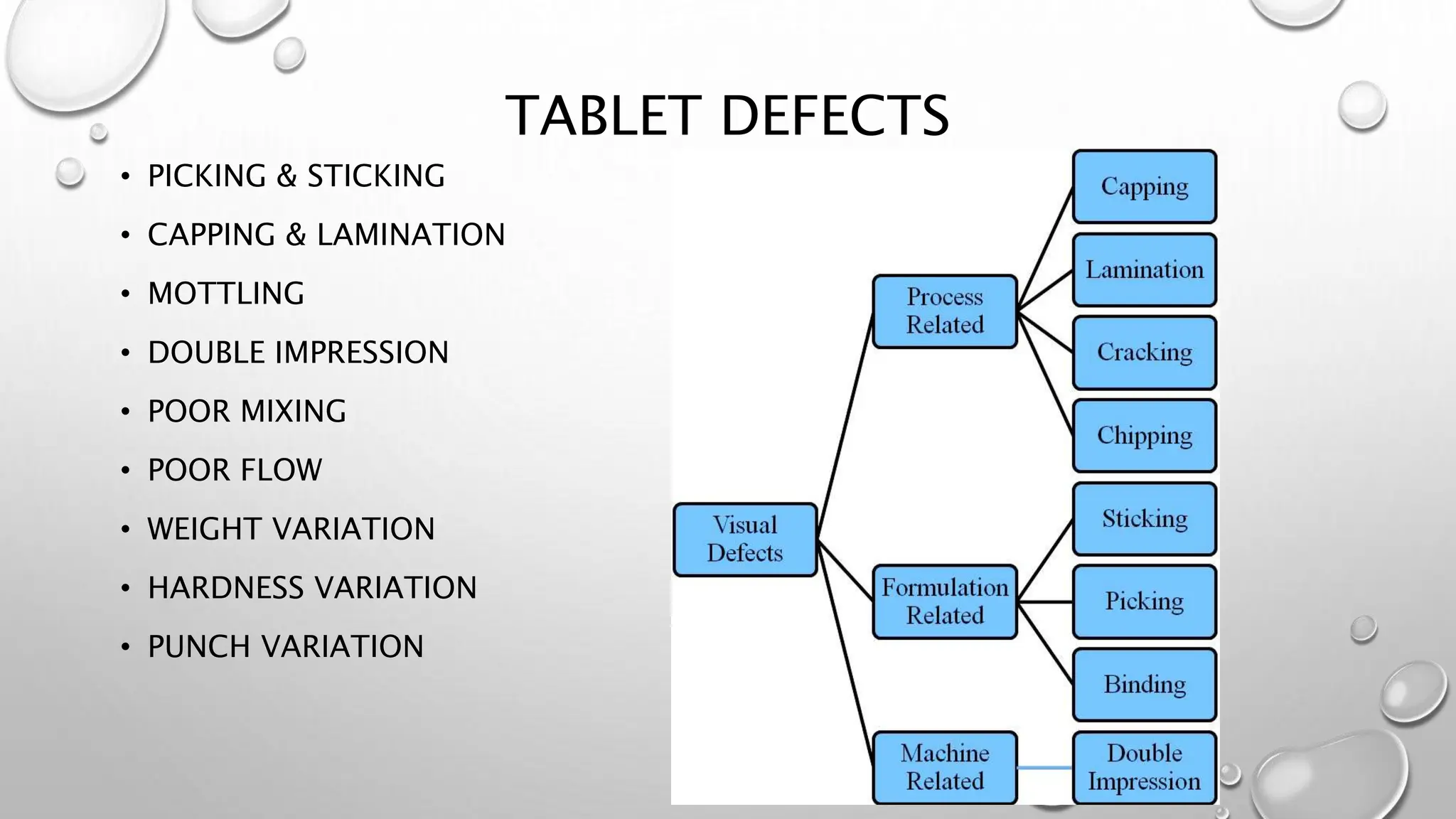

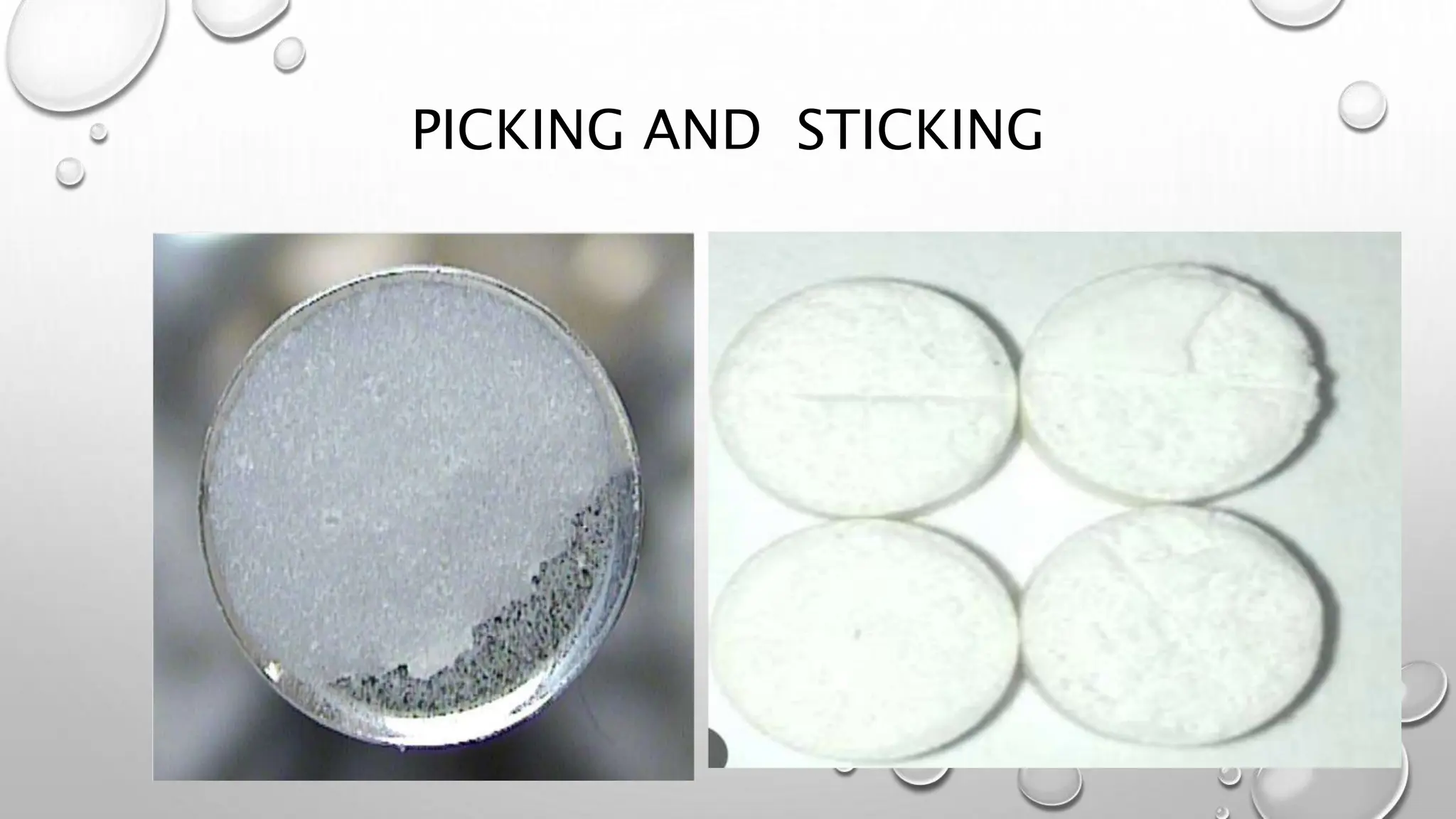

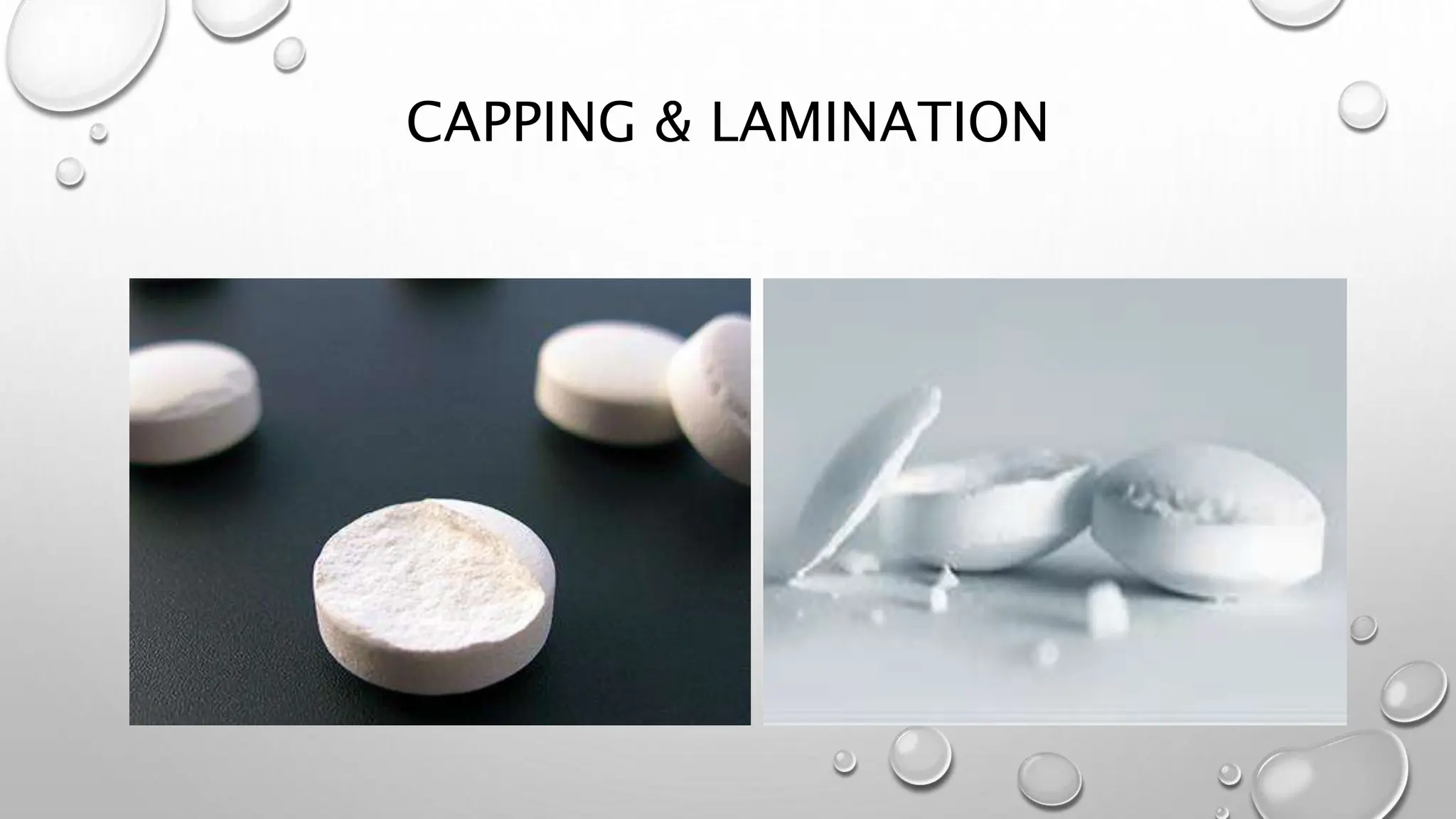

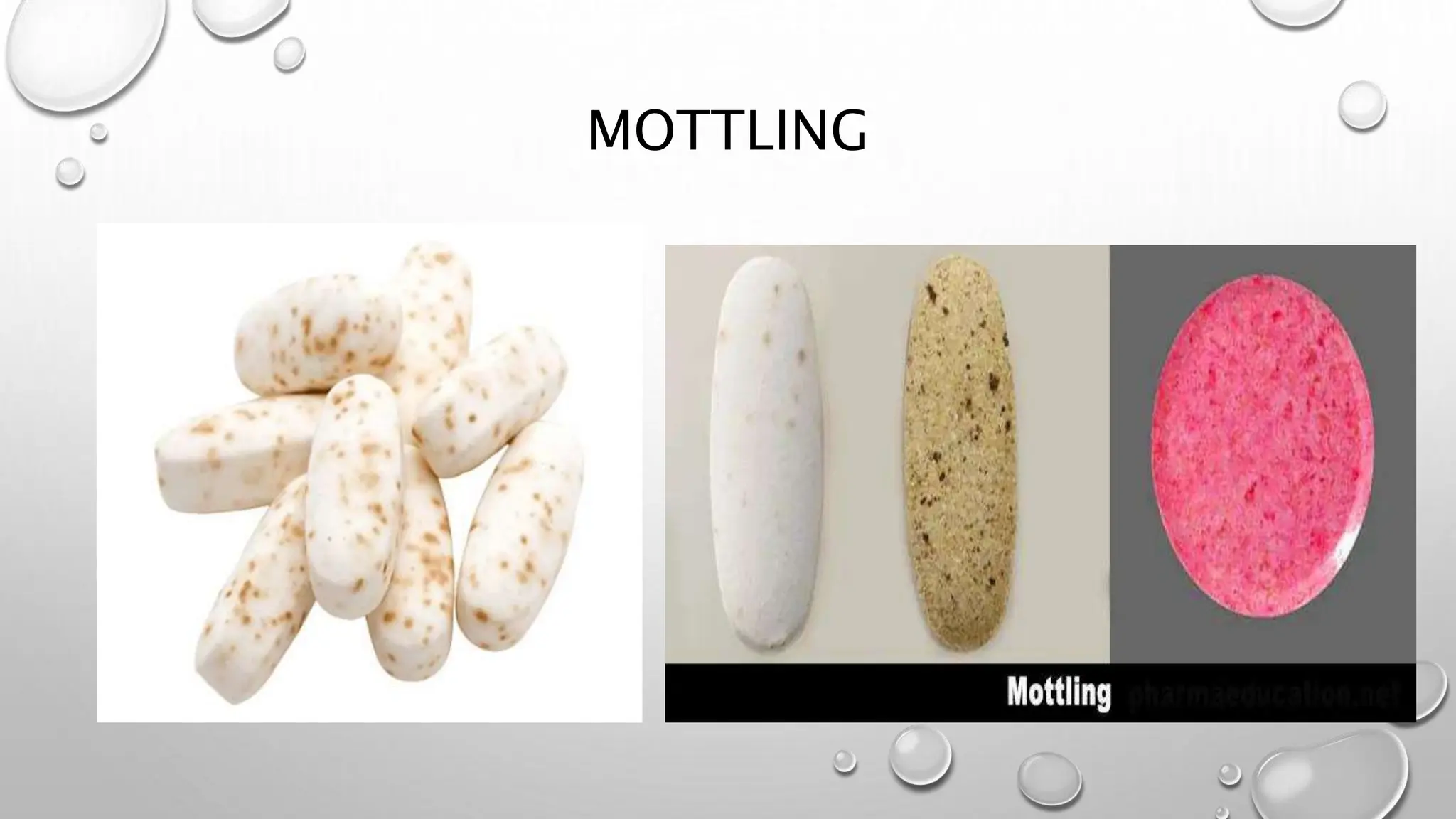

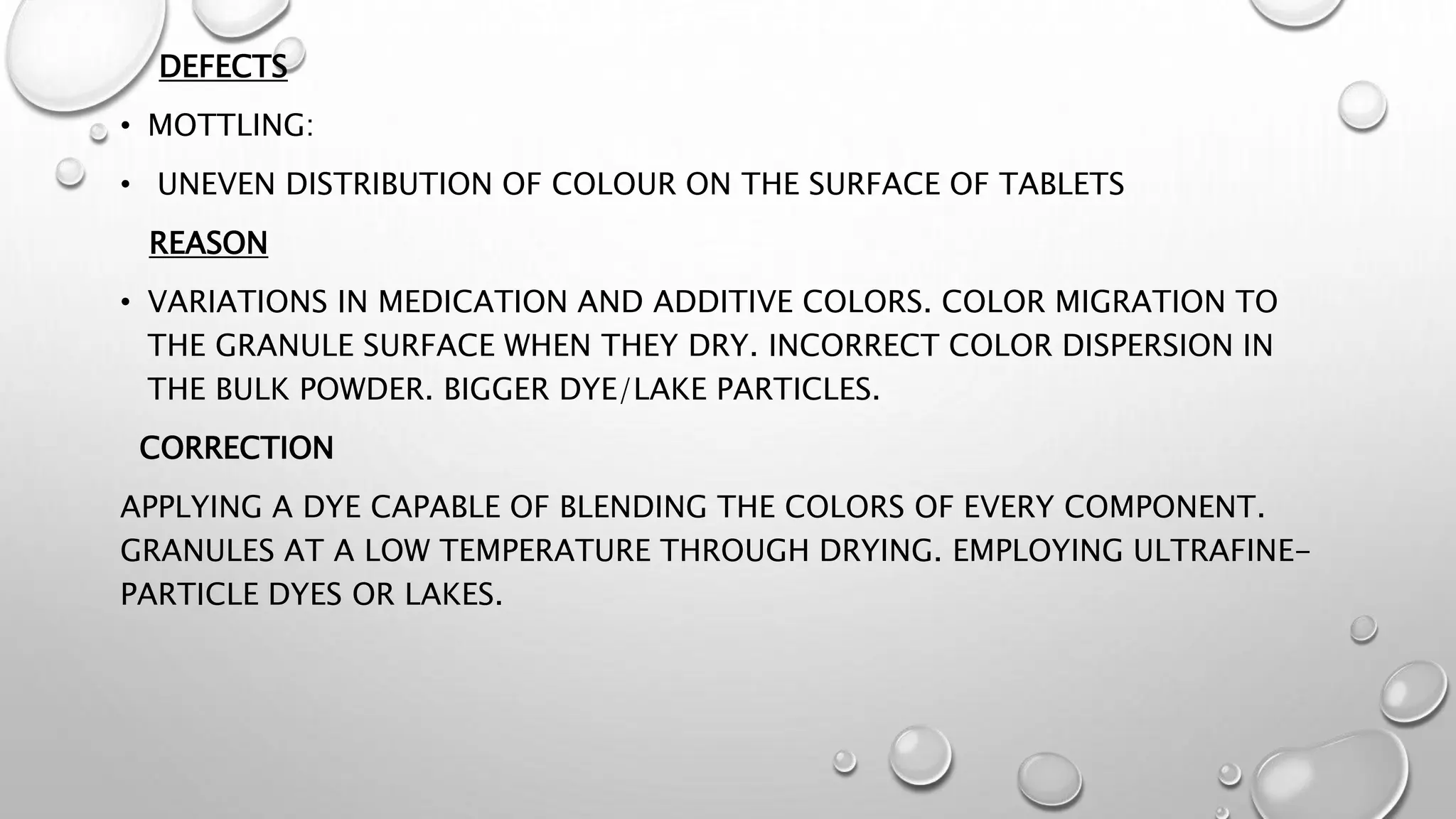

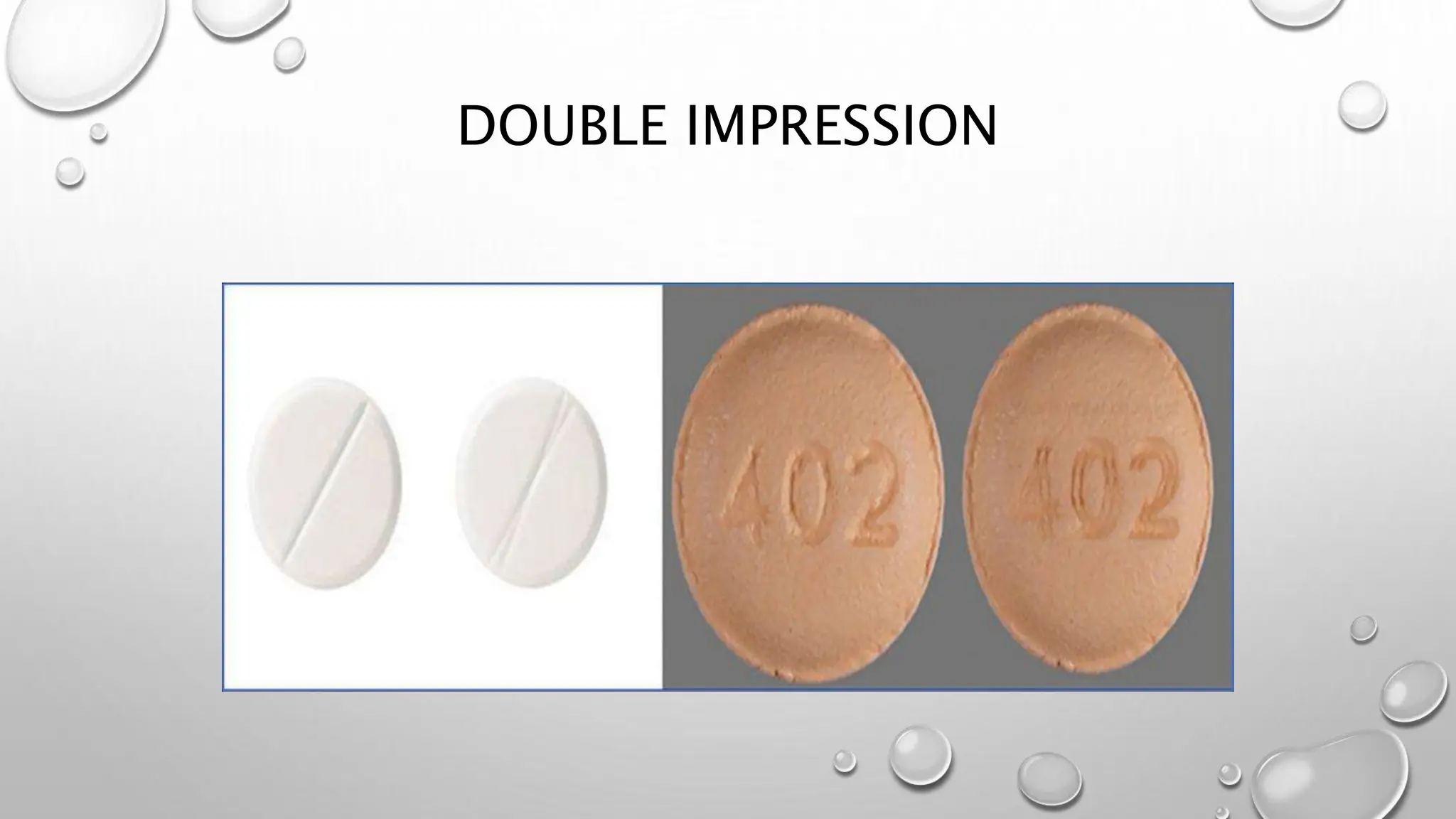

The document discusses tablet coating techniques, outlining their purposes such as protecting active ingredients and aiding in drug identification. It details three primary types of coatings: sugar, film, and enteric, along with their respective processes and equipment involved. Additionally, the document addresses various tablet defects, their causes, and corrective measures to ensure quality in tablet manufacturing.