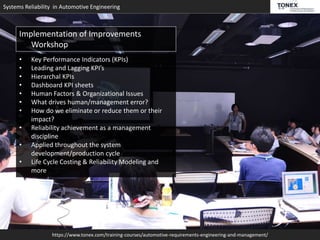

The document outlines a 2-day training course in automotive systems reliability engineering, focusing on concepts, tools, and techniques essential for implementing effective reliability programs. Participants will learn about fundamental reliability concepts, various predictive models, and management of reliability programs, aimed at professionals in the automotive industry. The course content covers reliability analysis, maintenance strategies, and condition monitoring techniques, making it suitable for a diverse audience including automotive engineers and business professionals.