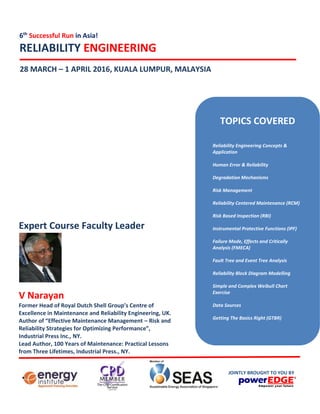

The Reliability Engineering course held from August 15 to 19, 2016, in Kuala Lumpur, Malaysia, focuses on key reliability engineering concepts and applications aimed at enhancing plant performance in various industries. Participants, limited to 20, learn essential reliability terminologies and tools, enabling them to improve maintenance strategies and analyze reliability-related metrics effectively. Conducted by V. Narayan, a former head at Royal Dutch Shell, the training includes hands-on exercises and discussions to bridge the gap between theoretical knowledge and practical applications in risk management and reliability improvement.