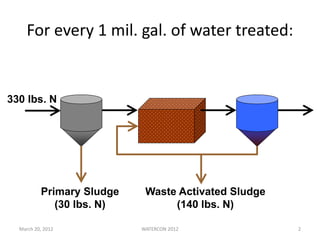

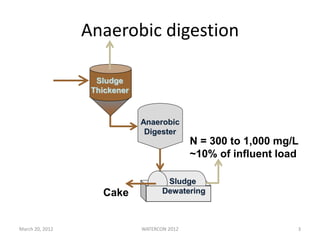

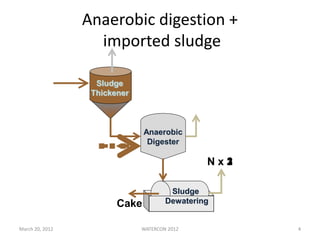

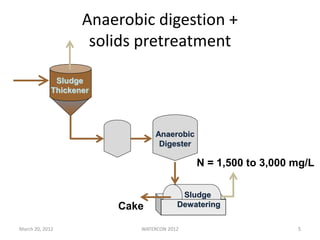

This document discusses various technologies for removing nitrogen from sludge dewatering liquor, including:

- Anaerobic digestion, which typically reduces nitrogen levels but additional treatment may be needed.

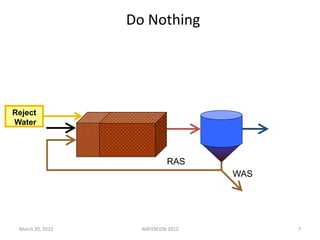

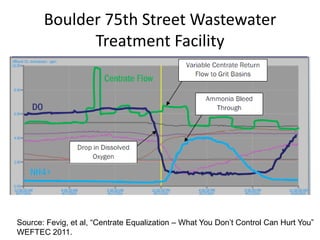

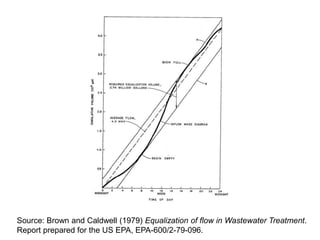

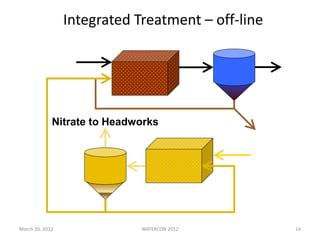

- Reject water handling alternatives such as doing nothing, exporting, attenuating through flow equalization, or treating through integrated or separate treatment processes.

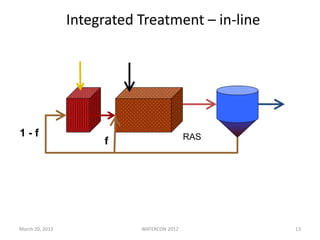

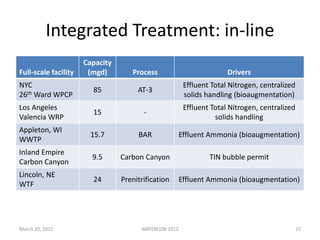

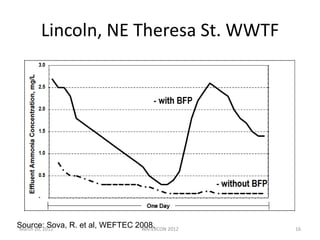

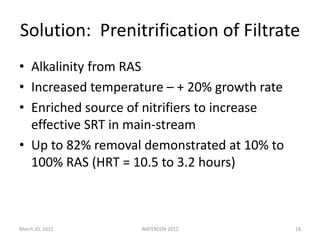

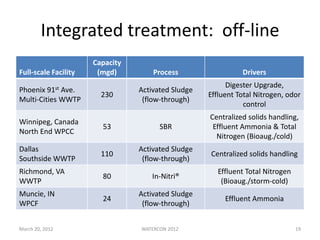

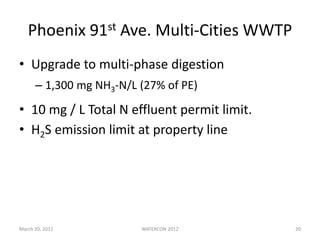

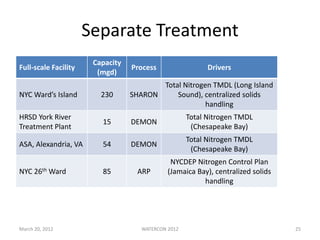

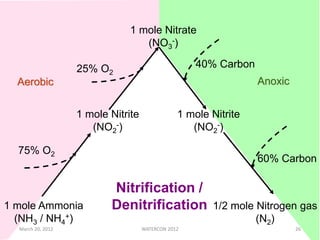

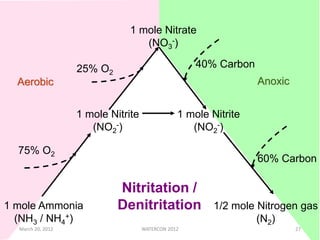

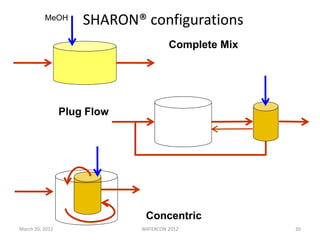

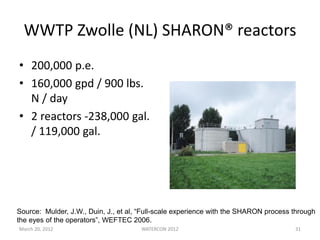

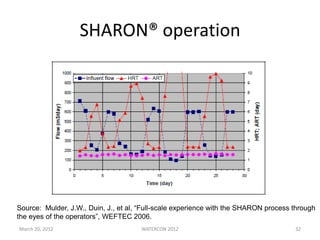

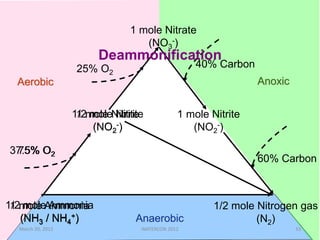

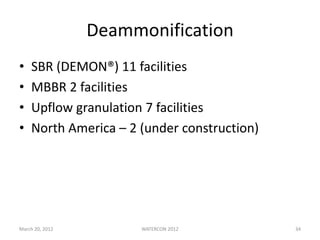

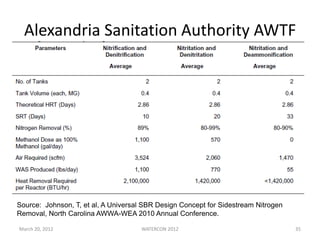

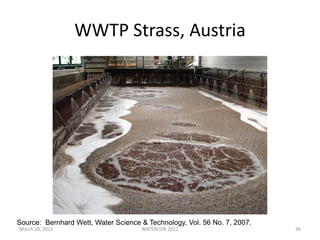

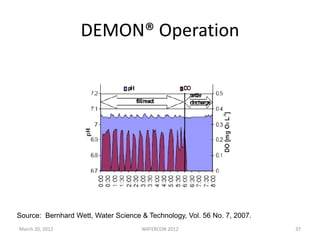

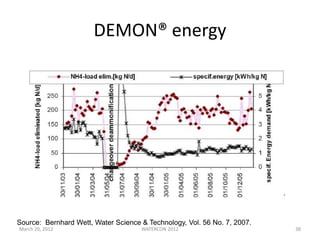

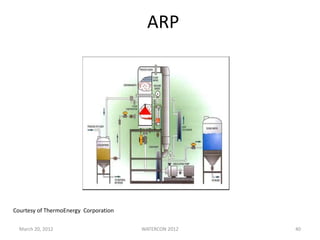

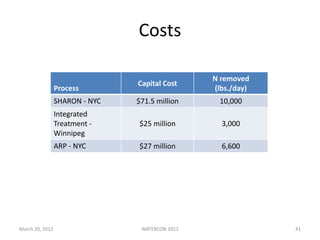

- Integrated treatment processes include in-line or off-line prenitrification of filtrate while separate treatment examples provided are SHARON, DEMON, and ammonia stripping processes. Capital and nitrogen removal costs are provided for some example full-scale facilities using these different technologies.