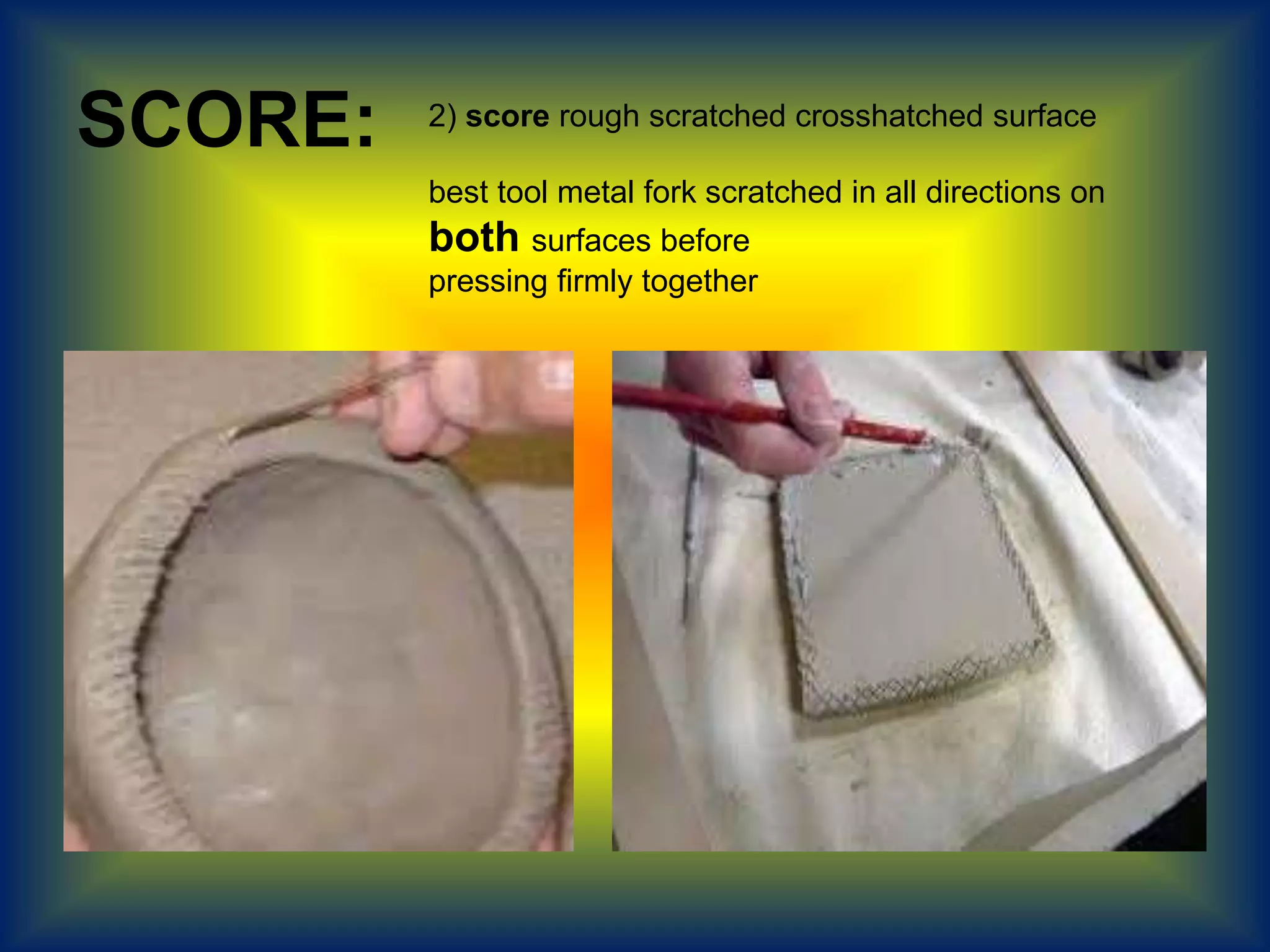

This document provides instructions for basic clay joining techniques and tips for ensuring clay projects survive the firing process. The key joining steps are to apply slip (clay liquid) to the surfaces, score the surfaces with a fork, and firmly press and blend the clay together at the seam. To avoid explosions during firing, clay pieces should not be too thick, should avoid trapped air pockets, and must be completely dry before firing. Proper drying and storage methods are also outlined.