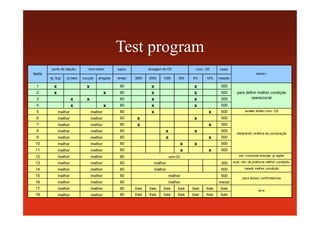

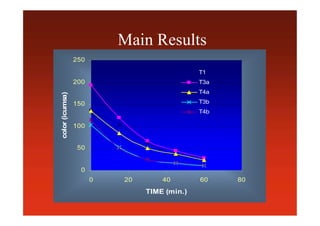

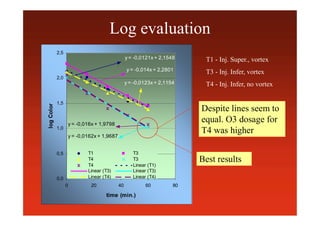

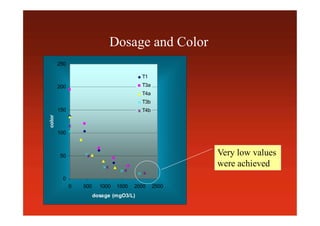

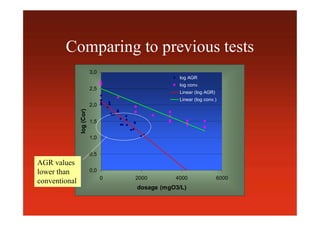

The document evaluates the feasibility of using ozone to bleach sugar in an agitated reactor (AGR), highlighting that while ozone application is effective, high consumption levels and off-flavors were observed at certain doses. Preliminary results show AGR performs better than conventional methods with a 30% reduction in ozone consumption, though further testing is necessary to optimize conditions and assess kinetics. Next steps include conducting additional tests with varying initial sugar colors and ozone concentrations.